Engineering and Technology

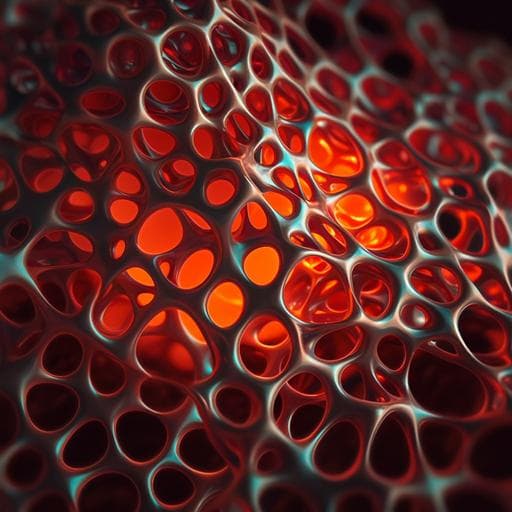

Tough and biodegradable polyurethane-silica hybrids with a rapid sol-gel transition for bone repair

S. J. Park, S. H. Im, et al.

Discover groundbreaking research by Su Jeong Park and colleagues on a novel biodegradable polyurethane-silica hybrid that showcases remarkable flexibility, biodegradability, and a unique shape memory ability. This innovative work accelerates bone regeneration through osteogenic differentiation and angiogenesis, promising exciting advancements in tissue engineering.

Related Publications

Explore these studies to deepen your understanding of the subject.