Engineering and Technology

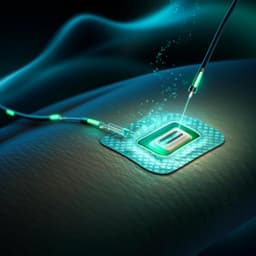

Skin-integrated, biocompatible, and stretchable silicon microneedle electrode for long-term EMG monitoring in motion scenario

H. Ji, M. Wang, et al.

The study addresses the challenge of long-term, accurate EMG monitoring hindered by the skin’s high-impedance stratum corneum and motion artifacts. Conventional Ag/AgCl wet electrodes require gels and skin preparation that can cause irritation and degrade over time as gels dry, leading to increased impedance and reduced performance. Dry electrodes avoid gels but suffer high contact impedance due to the stratum corneum. Microneedle-based dry electrodes can penetrate the stratum corneum to reduce impedance and improve stability. Prior work has explored various materials (epoxy siloxane/PDMS hybrids, stainless steel, PI) and fabrication methods (3D printing, KOH etching), but many solutions lack stretchability and robustness to accommodate skin deformation without needle rupture. This work proposes a plant-thorn-inspired, skin-integrated, biocompatible, and stretchable silicon microneedle electrode (SSME) with PI half-encapsulation of the microneedle shanks and serpentine interconnects, aiming to achieve stable, long-term EMG monitoring in motion scenarios with performance comparable to or better than wet electrodes.

The literature highlights limitations of wet Ag/AgCl electrodes, including the need for skin preparation, potential allergic reactions to gels/adhesives, drying-induced impedance drift, and motion artifacts. Dry electrodes reduce preparation burden but face high contact impedance because the stratum corneum is hydrophobic and a transport barrier. Microneedle electrodes mitigate this by piercing the stratum corneum, maintaining lower and more stable impedance. Reported microneedle electrodes include stainless-steel needles fabricated by DMLS 3D printing achieving comparable sEMG SNR to wet electrodes over ~6 hours, stainless-steel arrays on PDMS substrates tolerating significant tensile strain but with impedance variation under stretch, curved-substrate arrays for improved contact on fixed curvatures, and PI-molded microneedles integrated with flexible PCBs for high-density sEMG. Silicon microneedles fabricated by double-sided KOH etching with through-holes and silica-glass bonded sheets (KOH-scoring-KOH) have achieved competitive impedance density, yet silicon-based microneedles have typically lacked stretchability and raised concerns about robustness during motion. These gaps motivate the present stretchable, bioinspired silicon microneedle design combining semi-additive metallization and PI encapsulation for improved mechanical compliance and long-term stability.

Design: The SSME comprises a 6×6 array of silicon microneedles (height ~500 µm, base diameter ~350 µm, tip 10–50 µm), PI-encapsulated serpentine Au interconnects, and a 45 µm-thick semipermeable PU adhesive substrate (Opsite). Inspired by plant thorns (Radix Zanthoxyli), the microneedle shanks are half-covered by PI (top and bottom layers), increasing bonding area and reducing interfacial stress while leaving tips exposed for electrical contact. The serpentine interconnects act as bridges in an island-bridge architecture to accommodate stretch; microneedles act as islands. Fabrication (semi-additive process): 1) DRIE to form ~500 µm-tall Si pillars on double-side polished Si wafers (700 µm). 2) Isotropic wet etch in HF:HNO3:CH3COOH (3:25:10, mass) for 15–20 min to sharpen pillars into microneedles (HNO3 oxidizes Si to SiO2, HF removes SiO2, acetic acid buffers). 3) Oxygen plasma (5 min), then spin-coat polyamic acid (PAA) and fully cure to PI with a multi-step bake (80 °C 20 min; 120 °C 20 min; 150 °C 30 min; 180 °C 30 min; 200 °C 10 min; 220 °C 20 min; 250 °C 30 min). 4) Sputter Ti (20 nm) adhesion and Au (200 nm); spin-coat PR and pattern. 5) Electroplate Au to ~2 µm on exposed regions (serpentine interconnects); strip PR and wet-etch the protected thin Ti/Au (leaving 2 µm Au traces). 6) Spin-coat top PI, sputter Cu hard mask (~200 nm), lithographically pattern and RIE-etch both PI layers; remove unwanted metals. 7) Backside RIE to remove Si and transfer-print the device onto the PU substrate (microneedles protected by PDMS during transfer). Characterization: SEM used to verify microneedle morphology after wet etch, after PI, and after metal deposition; EDS mapping to confirm PI coverage along shanks. Mechanical testing: custom stretching stage applied repeated elongation; microscopy examined interconnects before/after 1000 cycles at 20% strain; additional tests up to 36–45% strain, with in situ resistance measurement; separate 100-cycle 24% strain test assessed skin-interface impedance pre/post loading. Finite element analysis (ABAQUS) modeled interfacial stress under 1 N shear for conventional vs PI-bonded (6 and 12 µm) microneedles (C3D8R elements) and simulated insertion into skin using a 2D axisymmetric model with a rigid microneedle, Neo-Hookean skin, refined mesh near contact, and friction coefficient 0.42; insertion force estimated. Electrical impedance: two-electrode method with an impedance analyzer scanning 10–1000 Hz for SSME vs wet electrode at 0 h and 6 h. Biocompatibility: PBS immersion (72 h) followed by SEM/EDS to assess corrosion; cytotoxicity with HacaT keratinocytes via CCK8 viability and Calcein AM/PI live/dead staining for four groups (entire SSME, microneedles without PU but with PI/metal/PI, bare Si, and blank control) at 24/48/72 h; statistics vs ISO 10993-5 threshold. Human tests and EMG acquisition: SSME as working electrode and wet electrode as reference; electrodes placed along target muscle (forearm flexor for fist clenching; biceps for high pull-down exercise). Custom wireless circuit included DA14580 Bluetooth SoC, ADS1118 16-bit ADC, W25X20CL flash, AD8232 analog front-end, and ME4057 battery charger. EMG recorded during intermittent and sustained fist clenching and during exercise at 0 h and 6 h; time- and frequency-domain features computed (RMS, IEMG, power spectra, MPF, MF). Ethical: informed consent obtained from participants.

- Stretchability and mechanical robustness: SSME tolerated at least 36% tensile strain with serpentine interconnects flipping out-of-plane; resistance remained stable (variation <0.5%) up to 45% stretch. After 1000 cycles at 20% strain, no cracks/delamination/wrinkles were observed; 100 cycles at 24% strain caused negligible change in electrode-skin impedance. FEA showed maximum microneedle/PU interfacial contact stress reduced by ~45% for PI-bonded microneedles (6 µm PI) relative to traditional design, with an additional ~10% reduction when PI thickness increased from 6 to 12 µm.

- Electrical impedance: SSME impedance decreased with frequency; compared to wet electrodes, SSME had higher impedance below ~40 Hz but lower from 40–1000 Hz, with overall similar magnitudes. Over 6 hours, SSME contact impedance remained stable (≈40–140 kΩ; slight decrease), whereas wet electrodes showed significant impedance increase, especially at low frequencies.

- Penetration and safety: Simulated insertion force to pierce skin estimated at ~0.1387 N. Skin imprints from SSME resolved fully within 2 hours with no redness; no abnormalities observed over 48 hours post-wear.

- Biocompatibility and stability in PBS: After 72 h PBS immersion, microneedle morphology and elemental composition were unchanged, indicating corrosion resistance. HacaT cytotoxicity tests showed ≥95% cell viability relative to control at 24/48/72 h for all test groups (p>0.05), exceeding ISO 10993-5’s 70% threshold.

- EMG performance: During intermittent and sustained fist clenching, SSME recorded EMG with higher amplitude, denser signals, and higher SNR than wet electrodes. Time-domain features (RMS and IEMG) were higher for SSME than wet electrodes. Frequency content for both centered in 20–150 Hz, with higher amplitudes for SSME. In long-term exercise (biceps during high pull-down), SSME signals at 6 h were comparable to 0 h, whereas wet electrode signals declined; SSME’s RMS and IEMG decreased much less than wet electrodes over 6 h.

The SSME design directly addresses the primary barriers to high-quality, long-term EMG monitoring: high skin impedance and motion artifacts. By piercing the stratum corneum, microneedles reduce the electrode-skin impedance and stabilize it over time, while the PI half-encapsulation and skin-like PU substrate enhance interfacial strength and conformability. The serpentine interconnects provide stretchability, allowing the device to accommodate skin deformation without compromising electrical continuity or needle integrity. Empirically, SSME matched or surpassed wet electrodes in impedance across the relevant EMG band and maintained stable impedance over 6 hours, unlike wet electrodes whose gel properties degrade and are influenced by environmental conditions. EMG recordings showed improved amplitude and SNR for SSME, translating to higher RMS and IEMG, and sustained performance during prolonged motion, confirming its suitability for continuous monitoring. Safety and biocompatibility were supported by rapid skin recovery post-insertion, lack of corrosion in PBS, and high cell viability. Collectively, the findings validate the bioinspired structural strategy as an effective solution for reliable, comfortable, and long-term EMG monitoring in dynamic scenarios.

The work demonstrates a bioinspired, skin-integrated, biocompatible, and stretchable silicon microneedle electrode capable of high-quality, long-term EMG monitoring during motion. The semi-additive fabrication yields robust PI-encapsulated microneedles and serpentine Au interconnects on a thin PU substrate, enabling >36% stretch with stable electrical performance and minimal fatigue over repeated strain. Compared to wet electrodes, SSME offers comparable impedance with superior long-term stability, higher EMG amplitudes and SNR, and better retention of signal quality after 6 hours of wear. Safety and biocompatibility are confirmed via simulations, skin recovery observations, PBS immersion, and cytotoxicity assays. Future work should pursue higher-density microneedle arrays for improved spatial resolution, integrate on-substrate signal processing ICs to digitize at the source and reduce transmission artifacts, and explore clinical applications in diagnosis and therapy using skin-integrated EMG interfaces.

While effective, the current SSME could benefit from: 1) higher-density microneedle arrays to enhance spatial resolution of EMG mapping; 2) monolithic integration of signal processing and digitization ICs on the flexible substrate to minimize analog transmission noise; 3) expanded application studies across diverse clinical conditions to validate diagnostic/therapeutic utility; and 4) broader long-term wear studies across varied environmental conditions and skin types.

Related Publications

Explore these studies to deepen your understanding of the subject.