Engineering and Technology

Quasi-equilibrium growth of inch-scale single-crystal monolayer α-In₂Se₃ on fluor-phlogopite

K. Si, Y. Zhao, et al.

The study addresses the challenge of growing large-area, single-crystal 2D semiconductors for electronics, where grain boundaries and crystallographic defects severely degrade device performance. Although epitaxial alignment using substrates with appropriate surface symmetry (3-fold or 6-fold) can promote single orientation, many 2D materials (e.g., MoS₂, h-BN) exhibit two locally stable orientations differing by 60° with a very small binding energy difference. In conventional CVD, dynamic, nonequilibrium conditions (uneven gas flow, inhomogeneous vapor distribution) can easily overwhelm this small energy difference, leading to mixed orientations and polycrystallinity. The paper proposes a quasi-equilibrium growth (QEG) strategy to reliably discriminate these small energy differences and achieve robust, inch-scale monolayer single-crystal α-In₂Se₃ on fluor-phlogopite, advancing integration of ferroelectric 2D materials in electronics and NVM.

Existing approaches to single-crystal 2D materials include: (1) phase transformation, whereby a polycrystalline film evolves into a single crystal via seeded transformation; and (2) epitaxial growth on single-crystal substrates with 3-fold or 6-fold symmetry or specific stepped surfaces (e.g., Cu(111), Al₂O₃/sapphire). Prior works showed that symmetry matching can favor a unique orientation, but small energy differences between two 60°-rotated states often persist, making growth sensitive to kinetic disturbances in open CVD systems and yielding orientation inconsistency. Recent progress includes wafer-scale epitaxy of TMDs and h-BN on single-crystal metals and sapphire, yet achieving uniform monolayer ferroelectric α-In₂Se₃ single crystals over inch-scale remains challenging due to metastable orientations and growth dynamics. The authors build on epitaxial symmetry principles, aiming to enforce the small thermodynamic preference through quasi-equilibrium conditions.

Quasi-equilibrium growth (QEG) of α-In₂Se₃ on fluor-phlogopite:

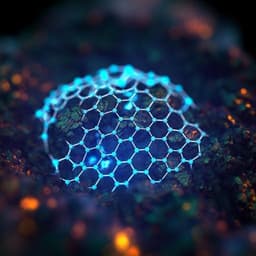

- Substrate selection and symmetry: Fluor-phlogopite (KMg₃AlSi₃O₁₀F₂) provides an atomically flat cleavage surface with effective 3-fold rotational symmetry due to surface hexagon distortion, matching α-In₂Se₃ (R3m). Lattice matching: α-In₂Se₃ in-plane lattice constant ≈ 4.026 Å; fluor-phlogopite surface ≈ 9.212 Å. A 7×7 α-In₂Se₃ supercell (28.182 Å) is commensurate with a 3×3 substrate supercell (27.637 Å), ≈1.9% mismatch, enabling epitaxial alignment.

- QEG concept and thermodynamics: The setup uses a semi-closed environment with the substrate fully covering the precursor boat and a small source–substrate gap (<1 mm), leading to similar temperatures and stabilized vapor pressure. Presence of a liquid intermediate (tiny In₂Se₃-containing droplets) further suppresses gas-flow disturbances. Using Clapeyron relation and small ΔT between source and substrate, the chemical potential difference Δμ is minimized (Δμ ≈ (ΔH/T)ΔT with ΔT ≪ T), establishing quasi-equilibrium among powder, vapor, and product. This allows the system to resolve the small binding energy difference between the 0° and 60° orientations, favoring single-orientation epitaxy.

- Growth steps: (1) Evaporation: Mixed α-In₂Se₃ and KI powders (mass ratio m(α-In₂Se₃):m(KI) = 30–90:1) are heated in H₂/Ar at atmospheric pressure; KI lowers the melting/evaporation temperature of In₂Se₃, producing a gaseous mixture that liquefies on the substrate into tiny droplets. Temperature is critical: at >760 °C, large droplets slide and leave irregular monolayer/few-layer ribbons with random orientations; at 720–760 °C, tiny clusters form triangular/hexagonal islands with uniform orientation. (2) Crystallization: Mobile clusters coalesce, attach at flake edges, and grow epitaxially into larger flakes. (3) Film formation: Same-oriented flakes stitch into continuous monolayer films. Growth is repeatable and tolerant across a broad window (temperatures 700–800 °C; precursor ratios 30:1–90:1). Deviations from semi-closed, short-gap conditions (e.g., changing substrates, solvents, or larger distances) move the system away from equilibrium and degrade uniformity.

- Experimental conditions (Methods): Tube furnace; H₂/Ar (50–1000 sccm, typically 5% H₂ in Ar); fluor-phlogopite substrates of 1×1 cm² or 3×3 cm² placed <1 mm above precursors in quartz boats; growth temperature 650–850 °C for 3–30 min at atmospheric pressure. Oxygen is purged prior to heating.

- DFT calculations: VASP with PBE-GGA, plane-wave cutoff 300 eV, convergence ≤1e−4 eV (energy) and ≤1e−2 eV/Å (force). A 3-fold symmetric α-In₂Se₃ flake on a monolayer fluor-phlogopite surface slab. Binding energies computed versus rotation angle; lowest at 0°, local minimum at 60°.

- Transfer and characterization: Wet PMMA transfer from fluor-phlogopite to SiO₂/Si or TEM grids; AFM (thickness ~0.9 nm), Raman (low-wavenumber α-In₂Se₃ peaks; mapping at 102 cm⁻¹), XRD (single-crystal peaks), EDS/XPS/AES (no K or I residues; Se/In ≈ 3:2), ADF-STEM and SAED (6-fold diffraction; consistent orientation across 9 grid holes over ~1 mm with ~2.8° deviation attributed to transfer), EBSD for grain orientation uniformity, H₂ etching (400 °C, 30 min) to generate aligned triangular holes.

- Device fabrication and measurements: Back-gated FETs on SiO₂(285 nm)/p++ Si; Ti/Au (10/40 nm) electrodes via lithography and e-beam evaporation; measurements in vacuum/dark using a Keithley 4200. Field-effect mobility extracted from μ = (∂I_D/∂V_G)·(L/(W C_i V_DS)), C_i ≈ 1.15×10⁻⁸ F cm⁻² (285 nm SiO₂). PFM on films transferred to Pt/Si to verify room-temperature ferroelectricity (phase hysteresis, ±10 V sweep). Heterostructures: monolayer MoS₂ (CVD-grown with NaCl-assisted method) transferred onto monolayer α-In₂Se₃ to form 1L-α-In₂Se₃/1L-MoS₂ Fe-FETs; arrays of 32 devices assessed for uniformity.

- QEG enables robust epitaxial alignment of monolayer α-In₂Se₃ on fluor-phlogopite by resolving small binding energy differences between 0° (global minimum) and 60° (local minimum) orientations predicted by DFT.

- Growth window tolerance: Temperatures 700–800 °C and precursor mass ratios 30:1–90:1 yield monolayer films by simply extending growth time; repeatable centimeter-scale films obtained in five consecutive runs.

- Large domain size: Individual α-In₂Se₃ flakes up to 1201 µm lateral size (at 760 °C, 60:1 ratio) stitch into continuous films; nearly 2-inch films demonstrated; monolayer thickness ~0.9 nm; atomically flat with no secondary layers/seeds.

- Structural/chemical quality: ADF-STEM interplanar spacing ~3.5 Å matching (11̄00); SAED shows 6-fold symmetry and consistent orientation across >1 mm with only ~2.8° deviation (transfer-induced). High-resolution XRD shows single-crystal peaks. STEM-EDS mapping shows uniform Se/In ≈ 3:2. No K or I detected by EDS, XPS, or AES.

- Device performance (single-crystal α-In₂Se₃ FETs, 13.1 nm thick channel): Mobility up to 117.2 cm² V⁻¹ s⁻¹ (reverse sweep), on/off ratio >10⁵, large clockwise hysteresis window up to −39.8 V at a sweep range of ±60 V (V_DS = 1 V). Retention >8000 s and endurance >8000 write/erase cycles (±60 V) with LRS current exceeding HRS by two orders of magnitude at V_GS = 0 V.

- Ferroelectricity: PFM confirms robust room-temperature ferroelectric behavior.

- Heterostructure Fe-FETs (1L-α-In₂Se₃/1L-MoS₂): Clockwise hysteresis with window ~100 V at sweep ±80 V (V_DS = 0.1 V); retention >20,000 s; endurance ≥10,000 cycles with stable HRS/LRS separation. Arrays of 32 devices show on/off >10² and hysteresis window >95 V for most devices, evidencing film uniformity.

- Mechanistic insight: Semi-closed, short-gap configuration and liquid intermediate establish quasi-equilibrium (small Δμ), minimizing kinetic disturbances and enabling selection of the thermodynamically preferred orientation consistent with symmetry matching and lattice commensurability (~1.9% mismatch).

The QEG strategy directly addresses the central challenge of achieving single-orientation epitaxy in 2D materials systems where two orientations are nearly degenerate. By enforcing quasi-equilibrium conditions—stabilized vapor pressure, minimal temperature gradient between source and substrate, and a liquid intermediate—the process suppresses kinetic fluctuations that typically produce mixed orientations in open CVD. DFT confirms that α-In₂Se₃ on fluor-phlogopite has a global binding energy minimum at 0° and a closely competing local minimum at 60°, so only under thermodynamically controlled conditions can the system reliably prefer the global minimum. The substrate’s effective 3-fold symmetry and acceptable lattice mismatch (~1.9%) enable parallel-aligned nucleation and stitching into single-crystal films. The resulting monolayer α-In₂Se₃ films exhibit exceptional crystallinity and uniformity over inch-scale areas, which translates to device-level benefits: high carrier mobility, low defect/doping signatures, and robust ferroelectric NVM behavior with long retention and strong endurance. Heterostructure devices with monolayer MoS₂ further demonstrate improved hysteresis windows and retention due to stronger built-in fields from interface charge trapping and efficient polarization in the ultrathin α-In₂Se₃. Collectively, these outcomes validate QEG as a broadly applicable route for large-area single-crystal 2D ferroelectric semiconductors and their integration into high-performance, low-power electronics and memory.

The work introduces a quasi-equilibrium growth (QEG) approach that leverages a semi-closed configuration, short source–substrate spacing, and a liquid intermediate to achieve inch-scale, monolayer, single-crystal α-In₂Se₃ on fluor-phlogopite. Symmetry matching (3-fold) and near-commensurate lattice constants enable monoorientation epitaxy, as supported by DFT. The films show outstanding crystalline quality and uniformity, enabling high-mobility Fe-FETs with long retention and robust endurance, and high-performance monolayer α-In₂Se₃/MoS₂ heterostructure NVM devices. Future directions include: extending QEG to other 2D materials and substrates; optimizing device stacks (e.g., thinner high-κ dielectrics) to reduce operating voltages; wafer-scale integration and patterning; and exploring complex 2D ferroelectric heterostructures for in-memory and neuromorphic computing.

- Process sensitivity to equilibrium conditions: Deviations from the semi-closed environment, small source–substrate distance, or liquid intermediate (e.g., alternative substrates/solvents, larger gaps) move the system away from quasi-equilibrium and hinder uniform film formation.

- Characterization constraints: Certain single-crystal assessments (e.g., EBSD/TEM) required films with limited grain sizes due to instrumental limitations; transfer-induced lattice distortions (~2.8°) were observed in SAED across mm-scale distances.

- Device stack constraints: The thick SiO₂ (EOT ~285 nm) limits gate field penetration and results in only partial polarization switching near the bottom surface, necessitating relatively high gate voltages (±60–±80 V) for NVM operation.

- Materials variability: For heterostructure arrays, variability in CVD-grown MoS₂ flakes can affect uniformity analysis, though devices still showed consistently high performance.

Related Publications

Explore these studies to deepen your understanding of the subject.