Biology

Photobiocatalytic synthesis of chiral secondary fatty alcohols from renewable unsaturated fatty acids

W. Zhang, J. Lee, et al.

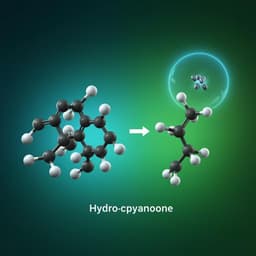

The study addresses the growing need for sustainable methods to convert biomass-derived fatty acids into valuable chemical building blocks. While traditional routes have focused on esterification (e.g., biodiesel) and other transformations (oxidative decarboxylation to alkenes, hydroxylations, epoxidations, and reductions), access to long-chain chiral secondary alcohols directly from natural fatty acids remains limited and often relies on multistep, non-selective chemical syntheses. The authors aim to develop a mild, selective, and modular biocatalytic strategy that converts unsaturated fatty acids into enantiomerically pure secondary fatty alcohols. The proposed approach leverages the chemoselectivity and light-driven activation of the fatty acid photodecarboxylase from Chlorella variabilis (CvFAP), combined with upstream oxyfunctionalisation by either fatty acid hydratases (FAHs) or a 5,8-diol synthase (AnDS). The central hypothesis is that a staged cascade—stereoselective hydration or dihydroxylation followed by photodecarboxylation—will deliver chiral secondary fatty alcohols from renewable starting materials with high enantioselectivity and functional-group tolerance under mild conditions.

Recent advances have broadened the biocatalytic toolbox for transforming fatty acids: (i) enzymatic (trans)esterification for biodiesel and specialty esters; (ii) decarboxylative alkene formation via P450 peroxygenases (OleT) and non-heme oxidases (UndA/B); (iii) terminal and subterminal hydroxylations using P450 monooxygenases, peroxygenases, and dioxygenases to yield hydroxy acids for polymer precursors; (iv) selective water addition to cis C=C bonds via hydratases; (v) lipoxygenase-mediated allylic hydroperoxidation followed by C–C cleavage or diol formation; (vi) reduction of carboxylates to aldehydes/alcohols by carboxylic acid reductases; and (vii) chemoenzymatic epoxidations leveraging lipase perhydrolase activity. The discovery of CvFAP introduced a light-driven, chemoselective decarboxylation of fatty acids to alkanes and enabled kinetic resolution of α-substituted acids, offering high functional group tolerance (leaving olefins and hydroxyls intact). However, direct biocatalytic access to long-chain chiral secondary alcohols from natural fatty acids has remained unmet, motivating the present cascade design combining FAHs or AnDS with CvFAP.

Biocatalyst preparation and expression:

- CvFAP production: Recombinant expression in E. coli BL21(DE3) using pET28a-His-TrxA-CvFAP in TB medium. Induction with 0.5 mM IPTG at OD600 0.7–0.8; 17 °C, 20 h. Cells harvested, lysed (cell disruptor), clarified, supplemented with 5% glycerol, aliquoted, and stored at −80 °C. Total protein quantified by BCA; expression verified by SDS-PAGE.

- Oleate hydratases: LrOhyA (from Lactobacillus reuteri; gene WP_109913811) cloned into pET28, expressed in E. coli BL21(DE3). Lyophilized whole cells used due to superior stability to cell-free prep. SmOhyA (from Stenotrophomonas maltophilia) co-expressed with CvFAP using E. coli BL21(DE3) pACYC-PelBSS-OhyA/pET28a-CvFAP.

- 5,8-Diol synthase (AnDS) from Aspergillus nidulans: Expressed in E. coli BL21(DE3) via pET21a-AnDS or improved periplasmic targeting construct pACYC-PelBSS-AnDS (PelB signal sequence), yielding ~10× higher rates and 2.3× higher final titers than cytosolic expression.

Cascade designs and reaction conditions:

- Cascade 1 (FAH + CvFAP): One-pot, two-step protocol to avoid decarboxylation of unhydrated olefins. Step 1 hydration: LrOhyA lyophilized cells (typically 15–20 g L−1) in Tris-HCl pH 8.0 (100 mM, 50 mM NaCl), 30 °C, 11 h; substrate 5–7 mM unsaturated fatty acid (e.g., oleic acid 1a). Step 2 decarboxylation: addition of CvFAP (2 μM), illumination with blue LED (λ = 450 nm; 13.7 mE L−1 s−1), typically 6 h. Control: empty E. coli cells showed no FAH or CvFAP activity.

- Monitoring: Conversion/time-course by GC (Cp sil 5CB, 50 m × 0.53 mm × 1.0 μm), GC/MS for identification (as needed), and 1H NMR. Enantiomeric excess determined by derivatization of alcohols with (S)-(+)-O-acetylmandelic acid followed by 1H NMR.

- Co-expression system: E. coli BL21(DE3) co-expressing SmOhyA and CvFAP used to intensify hydration and streamline operations. Reaction in Tris-HCl pH 6.5 (50 mM), 5 mM oleic acid, 7 g dry cells L−1. Hydration for 0.125 h, then blue light illumination (λ = 450 nm; 13.7 mE L−1 s−1) for 1.625 h for decarboxylation.

- Two-liquid-phase setup: Triolein used as hydrophobic organic phase (substrate reservoir/product sink). 20 mM oleic acid dissolved in triolein; aqueous buffer as above with LrOhyA and CvFAP. Optionally, addition of Candida rugosa lipase (CrLip) at the interphase to hydrolyze triolein in situ to oleic acid, followed by hydration and photodecarboxylation.

- Cascade 2 (AnDS + CvFAP): Dihydroxylation–decarboxylation cascade. Step 1: AnDS whole cells (7 g L−1) with oleic acid (15 mM) in HEPES pH 7.5 (50 mM) with 10% v/v DMSO, 40 °C, 2 h to form 5,8-dihydroxy-9(Z)-octadecenoic acid. Step 2: add CvFAP whole cells (7 g L−1) and illuminate (λ = 450 nm; 13.7 mE L−1 s−1) for 7 h to yield (Z)-heptadec-8-ene-4,7-diol.

Scale-up example:

- Linoleic acid (10 mM) in 98 mL Tris-HCl pH 8.0 (100 mM, 50 mM NaCl) with 2 g lyophilized LrOhyA cells, 30 °C, 48 h (hydration). Then CvFAP (2 μM, 2 mL stock added), blue LED illumination and stirring for 48 h. Workup by ethyl acetate extraction and flash chromatography to isolate the corresponding alcohol.

Analytical confirmation:

- Products and intermediates confirmed by GC, GC/MS, and NMR. Time courses presented for key transformations (oleic acid to 9-heptadecanol; AnDS diol route).

- Demonstrated a general photoenzymatic cascade to convert unsaturated fatty acids into chiral secondary long-chain alcohols via FAH hydration (or AnDS dihydroxylation) followed by CvFAP photodecarboxylation.

- One-pot two-step operation is crucial: Concurrent one-pot one-step led mainly to decarboxylation of unhydrated oleic acid into (Z)-heptadec-8-ene, as wild-type FAHs require a free carboxylate for hydration.

- Kinetics (oleic acid model, 7 mM): Full hydration within 11 h using LrOhyA whole cells (15–20 g L−1); subsequent photodecarboxylation was faster under 450 nm light at 13.7 mE L−1 s−1. LrOhyA stability and loading were limiting for overall rate.

- Substrate scope: A broad range of (poly)unsaturated fatty acids were transformed. Δ9-unsaturated fatty acids gave acceptable-to-good yields (24–74%) of the target secondary alcohols. In low-yield cases, the hydration step limited overall conversion; corresponding terminal alkenes from direct decarboxylation were major byproducts.

- Enantioselectivity: Alcohol products were generally obtained with high to essentially complete enantiomeric excess after derivatization with (S)-(+)-O-acetylmandelic acid and 1H NMR analysis (e.g., examples reported up to 99% ee for specific configurations, such as 7R/9R depending on substrate).

- Scale-up: Semi-preparative cascade with linoleic acid furnished 82.5 mg of the optically pure alcohol (32.5% isolated yield).

- Two-phase system: Using triolein as an organic reservoir with 20 mM oleic acid delivered 17.4 mM 9-heptadecanol (87% yield). Extending to a three-enzyme cascade (CrLip + LrOhyA + CvFAP) from triolein yielded 6.9 mM 9-heptadecanol; rapid acidification during hydrolysis slowed CvFAP activity, suggesting pH control can improve performance.

- Co-expression (SmOhyA + CvFAP in one E. coli host) significantly intensified hydration (over 90% oleic acid converted to 10-hydroxystearic acid within 7.5 min) with decarboxylation proceeding at comparable rates; remaining oleic acid was decarboxylated to (Z)-heptadec-8-ene.

- Dihydroxylation cascade (AnDS + CvFAP): 95% conversion of oleic acid to the diol intermediate within 1 h; subsequent photodecarboxylation produced (Z)-heptadec-8-ene-4,7-diol, with intermediates and products verified by GC/MS and NMR.

- Identified three key limitations: (1) low substrate loading due to poor solubility of lipophilic starting materials; (2) low overall rates dominated by the hydration step; (3) need for multiple catalysts/cell systems. Product titers remain below practical thresholds for industrial relevance.

The results validate the central hypothesis that combining selective oxyfunctionalisation of unsaturated fatty acids (via FAHs or AnDS) with light-driven CvFAP decarboxylation enables the synthesis of enantiomerically enriched secondary long-chain alcohols under mild conditions. The cascades exhibit broad substrate tolerance and high chemoselectivity, preserving C=C bonds and introducing stereocenters with high ee. Practical adaptations—namely, a one-pot two-step sequence, implementation of two-liquid phase systems, and co-expression of hydratase and photodecarboxylase—addressed key bottlenecks in solubility and productivity and demonstrated pathway modularity (e.g., upgrading triglycerides with an added lipase step). Nevertheless, the hydration step remains rate-limiting, and system acidification can inhibit photodecarboxylation, underscoring the need for better reaction control (pH, enzyme stability, and loading). The successful dihydroxylation–decarboxylation route further expands the chemical space toward diols, illustrating the potential of combining different oxyfunctionalising enzymes with CvFAP to access diverse, chiral functionalized hydrocarbons and alcohols from renewable fatty acid feedstocks.

This work establishes a versatile photoenzymatic platform to convert renewable unsaturated fatty acids into chiral secondary long-chain alcohols with high enantiomeric purity by coupling fatty acid hydratases or a 5,8-diol synthase with the photodecarboxylase CvFAP. The approach operates under mild, selective conditions and displays a broad substrate scope, including successful semi-preparative synthesis from linoleic acid. Process intensification via two-phase systems and co-expression demonstrates translational potential. Future research should target: (i) improving substrate solubility and loading (e.g., optimized biphasic media, surfactants, pH control); (ii) engineering FAHs and AnDS for higher activity/stability and expanded regio/stereoselectivity; (iii) enhancing CvFAP robustness to process conditions; (iv) integrating additional enzymatic modules (e.g., lipases for triglyceride feedstocks) for streamlined valorization; and (v) exploring biological properties and applications of the obtained chiral alcohols (e.g., antimicrobial activity) and scaling to economically viable titers.

- Substrate solubility constraints limit substrate loading and product titers, particularly with long-chain, lipophilic fatty acids.

- Hydration step (FAH activity/stability) is rate-limiting; high cell loadings (15–20 g L−1 lyophilized cells) are required for complete conversion in reasonable time.

- One-pot one-step operation is not feasible with wild-type FAHs due to preference for carboxylates; decarboxylation of unhydrated substrates dominates without staged operation.

- Two-phase, trienzymatic setups suffer from pH drops during triglyceride hydrolysis, inhibiting CvFAP; active pH control is necessary.

- Overall productivities and titers in this proof-of-concept remain too low for economic and environmental attractiveness; multiple catalysts/cell systems increase process complexity.

Related Publications

Explore these studies to deepen your understanding of the subject.