Food Science and Technology

Formation of contractile 3D bovine muscle tissue for construction of millimetre-thick cultured steak

M. Furuhashi, Y. Morimoto, et al.

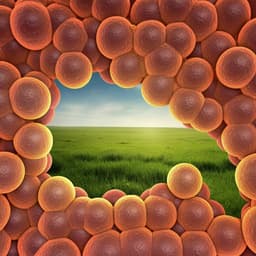

The study addresses the growing need for sustainable meat alternatives by developing cultured bovine muscle tissues suitable for steak, not just minced meat. Prior approaches produced small ring- or fiber-shaped constructs inadequate for steak-like texture. Large block-shaped tissues grown in porous gelatin or soy scaffolds yielded isotropic, low-density, non-contractile myotubes. The research question is how to construct millimetre-thick bovine muscle tissue with densely packed, unidirectionally aligned, mature, and contractile myotubes. The purpose is to define culture conditions (hydrogel composition and electrical stimulation) and a fabrication strategy that yield aligned, contractile tissues with properties relevant to steak, while assessing food-related characteristics such as stiffness and microbial load.

The paper situates cultured meat within sustainability and ethical contexts and reviews methods for muscle tissue engineering applied to bovine cells. Previous techniques formed ring-shaped tissues around agarose posts or fiber-shaped tissues between anchors, suitable for minced products. Block-shaped bovine tissues in porous gelatin or textured soy protein scaffolds enabled larger constructs but showed isotropic myotube orientation, low myotube density, and loss of contractility. Electrical stimulation and specific extracellular matrices (e.g., fibrin and Matrigel) have promoted myotube maturation in mouse, rat, and human systems, but optimal conditions for bovine muscle were unclear. The study builds on modular assembly approaches and alignment strategies from prior biohybrid devices and skeletal muscle engineering literature to achieve larger, aligned bovine muscle tissues.

- Cell sourcing and isolation: Bovine myocytes (myoblasts and satellite cells) were isolated from commercial fresh beef (Japanese black cattle, 27–30 months, male/female). Tissue was surface-sterilized (0.06% sodium hypochlorite), minced, and enzymatically digested (0.1% collagenase, 1000 U/mL dispase, 50 µg/mL gentamycin in DMEM, 37 °C, 1 h). Filtration (500 µm, then 70 µm) and centrifugation were performed. Cells were cultured in growth medium (DMEM + 10% FBS + gentamycin) at 37 °C, 5% CO2. Flow cytometry characterized cell populations; >85% were myocytes (myoblasts and satellite cells).

- Culture device for fiber-shaped tissues: Two stereolithography-fabricated anchors with protruding pillars were mounted 7 mm apart on an MPC-coated PDMS substrate to prevent adhesion. Anchors were parylene-coated and UV-sterilized.

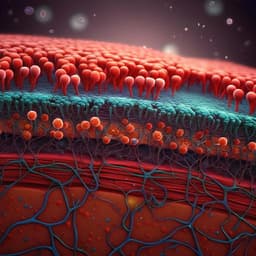

- Hydrogel conditions and seeding: Two hydrogels were tested: (1) type I collagen (2.4 mg/mL) and (2) fibrin-Matrigel mixture (4 mg/mL fibrinogen + 2 U/mL thrombin + 20% Matrigel). Bovine myocytes were mixed into hydrogel (5.0 × 10^7 cells/mL); 30 µL was cast to embed pillars and gelled at 37 °C for 15 min. Culturing: growth medium for 2 days, then differentiation medium (DMEM + 2% horse serum + gentamycin + 100 µM ascorbate phosphate + 100 ng/mL IGF-1) for 12 days with medium changes every 2 days.

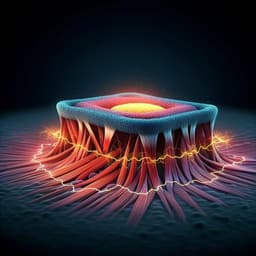

- Electrical stimulation regimen: Using a C-Pace EM system, tissues received pulses at 1 Hz, 2 ms duration, 3 V/mm, 2 h/day from day 3 to day 14. Contractile displacement in response to stimulation was assessed by microscopy and motion analysis.

- Immunostaining and morphology: Tissues were fixed (4% PFA), permeabilized (0.1% Triton X-100), blocked (5% BSA), and stained for α-actinin with appropriate secondary antibodies and Hoechst nuclear stain. Confocal microscopy (LSM780) was used. Myotube occupancy was quantified as α-actinin-positive area fraction on cross-sections. The fraction of myotubes with α-actinin sarcomeric stripes was counted from 3D stacks. FFT of images yielded directional distributions for alignment quantification.

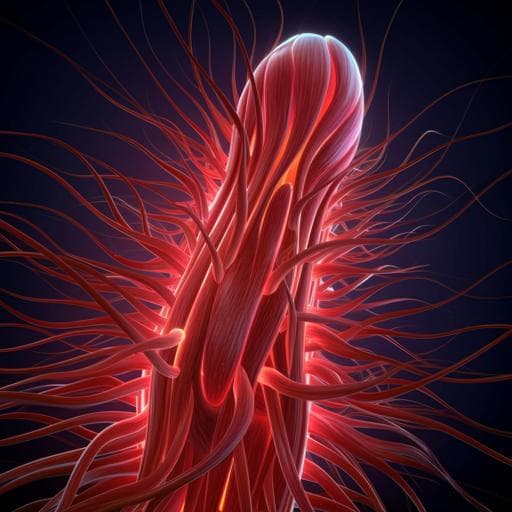

- Millimetre-thick tissue fabrication (module assembly): Collagen-based myocyte modules (2.4 mg/mL collagen; 1.0 × 10^7 cells/mL) were molded in PDMS templates to include end holes for pillars and internal slits forming striped structures to guide alignment. Two module types with different slit positions were alternately stacked onto pillars to form a 3D array. Forty modules with 1-mm-wide stripes and 0.3-mm spacing were stacked, immobilized on pillars, and cultured (1 day growth medium + 6 days differentiation medium) to fuse into a single construct. Control assemblies with 1-mm stripe spacing (1:1 width-to-interval) were also tested. H&E staining of 10-µm cryosections assessed integration and cell distribution.

- Food-related evaluations: After release from pillars, tissues were optionally colored with Food Red No. 40 (1 mg/mL, 30 s). Millimetre-thick tissues and commercial beef tenderloin were cut to 7-mm-high, ~0.5 g blocks, vacuum-bagged without air, heated at 70 °C for 1 h, cooled 30 min, and weighed to compute heating loss. Stiffness was evaluated via uniaxial constant-velocity indentation (EZ-TEST; 0.1 mm/s; 1.5-mm-diameter cylindrical indenter) to measure breaking force (n=1 per condition). Microbial load was quantified by plating PBS suspensions on standard agar (20 mL overlay), incubating aerobically 48 h at 35 °C, and counting CFU/g.

- Imaging and analysis: Macroscopic imaging documented construct formation (day 1 vs day 7), release from pillars, and post-coloring appearance. Alignment was further assessed by FFT-based directional plots on immunostained multi-module tissues (five-module stack) to overcome imaging depth limitations in fully millimetre-thick constructs.

- Contractility depends on hydrogel and electrical stimulation (ES): • Fibrin-Matrigel hydrogel: 100% of tissues with ES contracted (N=9); 56% without ES contracted (N=9). • Collagen hydrogel: 33% with ES contracted (N=6); 0% without ES (N=6). • Contractile displacement was larger in fibrin-Matrigel tissues than collagen under ES.

- Myotube maturation and density: • Myotube occupancy in cross-section (α-actinin area fraction): collagen 11% (no ES) → 20% (with ES); fibrin-Matrigel 17% (no ES) → 31% (with ES). • Fraction of myotubes with α-actinin sarcomeric stripes was highest (50%) in fibrin-Matrigel with ES. • Myotubes aligned along the long axis under all conditions by FFT analysis; ES + fibrin-Matrigel optimized maturation.

- Fiber-shaped tissue geometry: diameter 295 ± 105 µm (mean ± s.d., n=32); length matched 7-mm anchor gap.

- Millimetre-thick construct fabrication: • Stacking 40 collagen-based myocyte modules (1-mm stripes, 0.3-mm spacing) yielded a fused tissue of ~8 mm (W) × 10 mm (L) × 7 mm (H) after 7 days. • H&E sections showed uniform myotube distribution and integration of striped structures; enucleated cells were not observed (suggesting maintained viability and no central necrosis). • Using 1:1 stripe width-to-interval (1 mm spacing) failed to fuse, indicating intervals must be smaller than stripe widths. • Tissues could be released from pillars while maintaining integrity; food coloring imparted meat-like appearance.

- Food characteristics: • Heating loss at 70 °C for 1 h: cultured tissue 90% (0.31 g → 0.03 g) vs tenderloin 40% (0.52 g → 0.31 g), indicating higher water content in cultured tissue; acellular collagen gel melted entirely. • Breaking force (after heating; n=1): day 4 cultured tissue 0.11 N; day 14 cultured tissue 5.08 N; commercial beef tenderloin 6.11 N. Day 14 tissue approached tenderloin stiffness.

- Microbial load: cultured tissue (day 14) below detection limit (<5 cfu/g) vs tenderloin 1.7 × 10^5 cfu/g, demonstrating sterility advantages.

- Effective ES parameters used: 1 Hz, 2 ms pulse duration, 3 V/mm, 2 h/day from day 3 to day 14.

The study demonstrates that combining a fibrin-Matrigel matrix with low-frequency electrical stimulation robustly enhances bovine myotube formation, alignment, maturation (sarcomeric α-actinin), and contractility. This addresses the core challenge of producing steak-suitable tissues: generating dense, unidirectionally aligned, contractile myotubes at millimetre-scale thickness. The modular stacking approach with engineered striped structures and constrained spacing enables fusion into large, aligned tissues while maintaining viability and structural integrity, and it scales by increasing module number. Food-relevant analyses show that cultured tissues stiffen with culture time and approach tenderloin-like breaking force after heating, while retaining markedly lower microbial contamination than conventional meat, underscoring potential safety and shelf-life benefits. The findings align with mechanisms observed in other species, suggesting that ES-mediated maturation and ECM selection principles are conserved and translatable to bovine systems. Remaining differences in water content and myotube density highlight areas for further optimization to fully match conventional steak texture.

This work establishes a method to fabricate millimetre-thick, contractile bovine muscle tissues with highly aligned myotubes by optimizing hydrogel composition (favoring fibrin-Matrigel) and applying electrical stimulation, then scaling via stacked myocyte-laden modules with engineered alignment cues. The constructs exhibit sarcomeric maturation, robust alignment, increased stiffness over culture, and extremely low microbial loads, supporting their potential as cultured steak meat. Future directions include: developing edible hydrogel substitutes that recapitulate fibrin-Matrigel viscoelasticity; transitioning to serum-free or alternative nutrient media; optimizing ES parameters and hydrogel properties to further increase myotube density and maturation; automating module fabrication via 3D bioprinting and scaling myocyte production; and tailoring taste and nutrition using culture adjustments and food additives.

- Current matrices (collagen, fibrin-Matrigel) are not edible; identifying edible alternatives with similar viscoelastic properties is needed.

- Use of animal serum limits consumer acceptance and cost-effectiveness; serum-free or alternative media are required.

- Manual preparation and stacking of modules are labor-intensive and time-consuming; scaling demands automation (e.g., bioprinting).

- Large-scale production constrained by availability and expansion of bovine myocytes.

- Cultured tissues exhibited higher water content and lower myotube density than tenderloin, affecting heating loss and texture; further maturation and densification are necessary.

- ES parameters were not comprehensively optimized; different frequencies/amplitudes may yield improved outcomes.

- Mechanical testing was limited (n=1) for food texture comparison, necessitating broader sampling for robust statistics.

Related Publications

Explore these studies to deepen your understanding of the subject.