Engineering and Technology

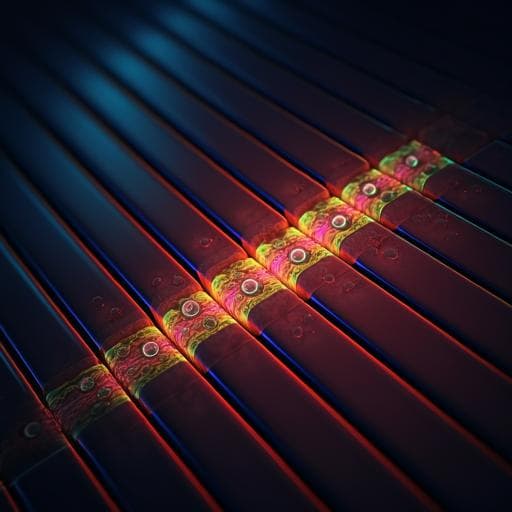

Design and fabrication of a vigorous “cavitation-on-a-chip” device with a multiple microchannel configuration

F. R. Talabazar, M. Jafarpour, et al.

Discover the groundbreaking 'cavitation-on-a-chip' device developed by Farzad Rokhsar Talabazar and his team, featuring eight innovative microchannels that significantly lower the pressure needed for hydrodynamic cavitation. This advancement opens doors for applications in drug delivery and tissue engineering.

~3 min • Beginner • English

Related Publications

Explore these studies to deepen your understanding of the subject.