Engineering and Technology

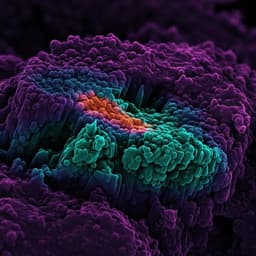

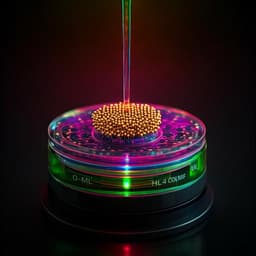

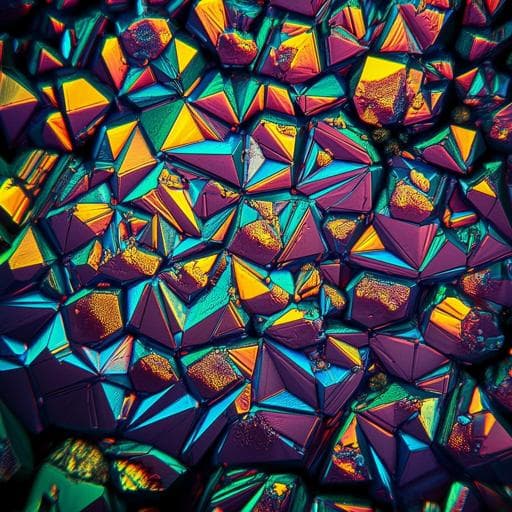

Controlled on-chip fabrication of large-scale perovskite single crystal arrays for high-performance laser and photodetector integration

Z. Xu, X. Han, et al.

Discover a groundbreaking method for fabricating large-scale perovskite single crystal arrays with precision control, developed by Zhangsheng Xu and colleagues. This innovative technique allows for tunable pixel dimensions and exceptional quality factors, paving the way for advanced integrated photodetector systems.

Related Publications

Explore these studies to deepen your understanding of the subject.