Engineering and Technology

Wireless, battery-free, and real-time monitoring of water permeation across thin-film encapsulation

M. Mariello, J. D. Rosenthal, et al.

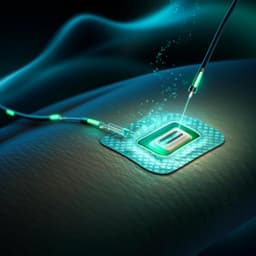

Soft, flexible bioelectronic implants demand thin-film encapsulations (TFEs) that are hermetic, flexible, and microfabrication-compatible to ensure long-term reliability in aqueous, ionic biological environments. Water permeation is the principal cause of barrier failure, leading to short circuits, corrosion, and delamination. Conventional water transmission rate (WTR/WVTR) measurements rely on bulky, low-sensitivity permeation cells unsuited for miniaturized implants, while calcium tests require inert processing and are not readily compatible with fabrication and integration into devices. Recent work suggests Mg as a viable corroding sensor metal that is more fabrication-friendly than Ca. However, in situ, real-time, wireless quantification of permeation across TFEs in flexible/implantable formats remains unaddressed. This study introduces a wireless, battery-free backscatter platform that converts Mg corrosion into a frequency shift of a tunable RF backscatter circuit, enabling direct extraction of WTR from a single operational parameter (oscillation frequency) for in situ monitoring in vitro, ex vivo, and in vivo-like conditions.

The paper surveys TFE strategies including organic polymers (polyimide, parylene C, liquid-crystal polymers) and inorganic thin films (Al2O3, SiNx, SiO2/SiOx, SiC) and hybrid multilayers (ALD oxides with organic interlayers), highlighting their use in flexible implant encapsulation. It describes limitations of standard WTR measurements (permeation cells) and the calcium test’s stringent deposition requirements and incompatibility with integration. Prior Mg-based corrosion sensing of water permeation is introduced as more robust to ambient processing and miniaturization, but previous work lacked demonstration in flexible/stretchable substrates and fully wireless operation suited for actual implants. The authors position their backscatter-based, battery-free approach as addressing these gaps, with references to backscatter communication advances for low-power implants and implantable antenna design and wireless powering literature relevant to in-body links.

System architecture: A battery-free wireless platform employs RF backscatter communication. An external interrogator transmits an RF carrier; the implantable tag modulates its antenna impedance using a single-pole RF switch driven by a tunable square-wave oscillator. The oscillator frequency fosc is controlled by a resistance network including the Mg sensing element (R_Mg). As Mg corrodes upon water ingress through the encapsulation, R_Mg increases, lowering fosc. The backscattered spectrum exhibits subcarrier tones at fc ± fosc; tracking fosc over time yields WTR through an analytical model.

Electronics and calibration: A CMOS square-wave oscillator (LTC1799) provides resistance-to-frequency conversion with fosc tuned by R_set via: fosc = ψ / R_set (ψ = 10 kΩ·10 MHz), with R_set implemented as a parallel network of a fixed resistor R_fix and R_Mg: R_set = R_fix (R_fix + R_Mg)/(2R_fix + R_Mg). Sensitivity S_osc = dfosc/dR_Mg = −ψ R_fix / [R_set (2R_fix + R_Mg)]. Device operation targeted fosc ≈ 3.5–4 MHz for high sensitivity (~35 Hz/Ω). The RF switch (Analog Devices ADG919) toggles the antenna impedance at fosc. A LDO (LP5907) regulates supply. Rigid WPS consumed ~5 mW at 2.7 V; flexible i-WPS consumed ~3.5 mW at 2.8 V.

Backscatter link: External RF generator transmitted at 2.394–2.65 GHz depending on setup. A spectrum analyzer (100 Hz RBW, 100 kHz span) recorded the backscattered subcarrier peaks every 30 s. Frequency-only tracking is robust against amplitude variations from environmental or tissue dielectric changes.

Mg sensor fabrication: Flexible Mg test sensors were fabricated on 5 µm PI (polyimide) with Ti/Pt interconnects, 200 nm thermally evaporated Mg patterned as stripes or serpentines, and capped by an additional 5 µm PI. After corrosion, Mg converts to Mg(OH)2 (confirmed by XRD, SEM/AFM, and FIB-EDX cross-sections). Multiple geometries were designed to assess geometry effects on corrosion kinetics while keeping thickness constant.

Encapsulations: Tested barriers included PI (5 µm), PI with parylene C bilayer (5 µm PI + 5 µm parylene C by RT-CVD), and hybrid organic–inorganic multilayers (parylene C/ALD Al2O3/TiO2 dyads with a 5 nm Al2O3 seed and parylene C capping). Deposition parameters and ALD growth per cycle are provided; devices were hung vertically for conformal deposition.

Experimental setups: In vitro soaking in PBS (pH 7.4) at controlled temperatures (37 °C, 67/73 °C, 85 °C). An automated LabVIEW-controlled system synchronized frequency tracking and, for calibration, simultaneous resistance measurements via a microcontroller-controlled switch to a voltage divider (100 Ω in series with Mg). Ex vivo tests placed flexible i-WPS intramuscularly in chicken tissue submerged in PBS at 37 °C. In vivo-like tests implanted a miniaturized i-WPS subcutaneously in freshly euthanized mice maintained at 37 °C, with controlled antenna orientations and distances.

Wireless power and antenna: Inductive wireless power at 13.56 MHz via a 2.39 µH on-board receiver coil and external transmitter coil; rectification with a full-wave diode rectifier. The backscatter antenna is a flexible, meandered dipole designed for implantation (target ~2.4–2.65 GHz), with a chip balun and π-matching network optimized in tissue-mimicking phantoms; measured input impedances and S11 confirmed ISM-band coverage. Silicone encapsulation protected the electronics and ensured tissue compatibility.

Modeling and WTR extraction: The WTR is derived from fosc(t) using an analytical relation (parameters known from geometry and circuit): WTR = −K α ψ / (2ψ − R_fix fosc)^2 · dfosc/dt, where K depends on physical and geometrical parameters of the Mg sensor and encapsulation. Data analysis identified diffusion-driven initial regime, transitional regime as Mg(OH)2 formed, and late-stage stabilization dominated by the hydroxide barrier.

- The platform enables wireless, battery-free, real-time monitoring of water permeation across TFEs by tracking the frequency shift of a backscattered RF subcarrier governed by Mg sensor corrosion.

- Sensitivity and power: Tuned operation at 3.5–4 MHz provided ~35 Hz/Ω sensitivity to R_Mg changes; rigid WPS consumed ~5 mW at 2.7 V, flexible i-WPS ~3.5 mW at 2.8 V.

- PI encapsulation (5 µm, PBS, 85 °C): Initial WTR (first ~15 min) averaged 8.12 × 10^-1 g m^-2 day^-1 (RMSD 2.35 × 10^-1 g m^-2 day^-1; SD 4.56 × 10^-1 g m^-2 day^-1). As Mg(OH)2 formed, WTR decreased and stabilized at ~1.2 × 10^-6 g m^-2 day^-1, consistent with a hydroxide-dominated barrier; final drop indicated corrosion completion.

- Temperature dependence and activation energy: For PI-encapsulated sensors, higher temperatures increased WTR; Arrhenius analysis yielded an activation energy of 16.46 kcal mol^-1.

- PI/parylene C bilayer: WTR at 85 °C was lower than PI-only, confirming improved barrier performance; Arrhenius activation energy was 21.11 kcal mol^-1. The transmission rate of parylene C alone, extrapolated from multilayer diffusion theory, matched literature values.

- Hybrid organic–inorganic multilayer (PI with 3 dyads of parylene C/Al2O3/TiO2 plus seed and cap): Initial average WTR ~8.2 × 10^-2 g m^-2 day^-1, peaking early before stabilizing to ~4.5 × 10^-2 g m^-2 day^-1 post-saturation; abrupt loss later due to electrical disconnection. Results indicate defect-decoupling and significantly lower WTR vs homogeneous polymers.

- Geometry effects: Sensor geometry (width/shape) did not significantly affect normalized initial WTR but influenced time-to-completion (wider tracks contained more Mg and corroded longer).

- Ex vivo intramuscular chicken tissue: Clear backscatter peaks at fc ± fosc were observed; Mg insert (5 µm PI encapsulation) corroded to completion in ~12 h, similar to in vitro at 85 °C, indicating a more aggressive ionic/protein environment than PBS.

- In vivo-like mouse cadaver (subcutaneous): The miniaturized i-WPS maintained a stable link; extracted WTR on the order of 2 × 10^-6 g m^-2 day^-1. Backscatter frequency encoding proved robust to variations in antenna orientation, animal posture, and minor environmental changes.

- The method distinguishes homogeneous polymer diffusion from inhomogeneous, defect-driven diffusion in hybrid stacks, demonstrating sensitivity to real barrier integrity features relevant to implant reliability.

The study addresses the critical need for in situ, real-time quantification of water permeation in thin-film encapsulations for flexible implants. By encoding Mg corrosion progress as a frequency shift of a backscattered RF subcarrier, the platform robustly reports WTR independent of received signal amplitude, mitigating issues from variable antenna gain, tissue dielectric changes, and reader-tag geometry. The analytical model allows direct conversion of df/dt to WTR using known device and circuit parameters. Validation across multiple encapsulations (PI, PI/parylene C, hybrid multilayers), temperatures, and tissues demonstrates accuracy and robustness, including differentiation between homogeneous diffusion and localized defect-driven permeation typical of organic–inorganic laminates. Ex vivo and in vivo-like tests confirm feasibility for subcutaneous and intramuscular deployment with low power budgets and small form factors. The results suggest the platform can serve as a predictive tool linking accelerated in vitro aging to in-tissue performance, aiding encapsulation selection and quality control for chronic bioelectronic implants.

This work introduces a wireless, battery-free, backscatter-based sensing platform that converts Mg corrosion into a frequency signal for direct, real-time extraction of WTR in thin-film encapsulations. The system integrates a sensitive resistance-to-frequency oscillator, implant-optimized antennas, and inductive power, demonstrating operation in vitro, ex vivo, and in vivo-like settings. Key contributions include: a robust frequency-encoded readout immune to amplitude fluctuations; quantified WTR and activation energies for common encapsulations; and demonstration of miniaturized, flexible implants suitable for small animals. Future directions include optimizing wireless power rectification (e.g., multi-stage Greinacher), consolidating power and data to a single RF frequency, ASIC integration for further miniaturization, BLE-compatible backscatter for smartphone-based readers, deep-body antenna and matching redesigns guided by full-body EM simulations, and multi-sensor layouts to spatially map encapsulation integrity across implants.

- Reported WTR values for some multilayer datasets may be influenced by localized defects (pinholes, microcracks), producing inhomogeneous diffusion; while detectable, this complicates direct comparison to homogeneous polymer barriers.

- Minor frequency or amplitude fluctuations can occur due to sensor bending or changes in tissue dielectric properties; although frequency encoding mitigates amplitude sensitivity, mechanical deformation may still introduce small perturbations.

- Ex vivo and in vivo-like cadaver tests approximate but do not fully replicate live physiological conditions; deep-body implantation introduces higher in-body path loss and matching sensitivity, requiring site-specific antenna optimization.

- The Mg-based sensing localizes measurement to the area above the Mg resistor; mapping full-device encapsulation reliability would require multiple distributed sensors.

- Wireless power and rectification require careful design to ensure stable supply; the presented rectifier topology can be improved for higher efficiency and SNR.

Related Publications

Explore these studies to deepen your understanding of the subject.