Engineering and Technology

Versatile self-assembled electrospun micro-pyramid arrays for high-performance on-skin devices with minimal sensory interference

J. Zhang, Z. Li, et al.

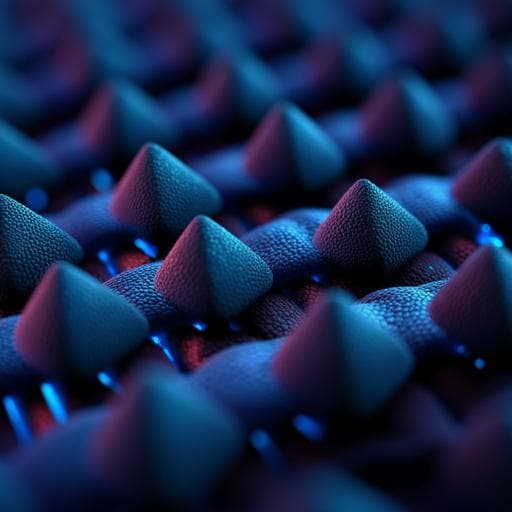

On-skin devices can detect physiological and action signals, provide protection, and convert biomechanical energy, with applications in healthcare, behavior monitoring, self-powered electronics, and human–machine interaction. As these applications mature, devices must be imperceptible for long-term, comfortable wear and cause minimal interference to natural tactile sensation to enable advanced scenarios such as learning skilled manipulation or restoring limb function. Prior imperceptible on-skin films, often ultrathin, ultralight, and gas-permeable, have largely flat functional surfaces due to limitations of fabrication such as random electrospinning deposition, leading to inferior optical, thermal, mechanical, and electrical performance compared with 3D microstructured surfaces. Three-dimensional microstructure arrays (micropyramids, microcones, microdomes, microprisms) offer gradient space-filling, stress distribution, and refractive index, advantageous for regulating force, heat, light, and electricity. However, existing fabrication (photolithography, 3D printing) struggles to combine gradient geometry with ultrathin, ultralight, gas-permeable structures. The study addresses this challenge by proposing electrospun micropyramid arrays (EMPAs) formed via self-assembly of wet heterostructured electrified jets to achieve structurally designable, permeable, ultrathin, and ultralight 3D arrays that enhance performance while maintaining imperceptibility across radiative cooling, pressure sensing, and bioenergy harvesting.

The authors reference prior developments in imperceptible on-skin electronics emphasizing ultrathin, ultralight, gas-permeable films (e.g., Someya’s group). They note that these films typically have flat surfaces due to electrospinning deposition constraints, limiting multifunctional performance. Literature shows 3D microstructures (micropyramids, microcones, microdomes, microprisms) provide advantages via gradient space filling, stress distribution, and refractive index, beneficial for optics, thermals, mechanics, and electronics. Conventional fabrication routes for such arrays (photolithography, 3D printing) cannot simultaneously achieve gradient geometry, gas permeability, ultralow thickness, and low weight. The work situates itself relative to reported micropyramid-array-based flexible devices for pressure sensing and energy harvesting, aiming to combine superior performance with imperceptible wearability by leveraging a self-assembly electrospinning approach.

Fabrication of EMPAs: A far-field electrospinning setup with a grounded aluminum foil collector is used. Wet heterostructured electrified jets deposit onto the collector, forming inhomogeneously charged microdomains. Positive aerial jets preferentially deposit on negatively charged, PVDF-rich areas via electrostatic attraction, leading to fibrous domes when the substrate thickness reaches several microns. Electrostatic induction and polarization concentrate negative charge at dome tops with locally higher electric field, causing single fibers to bridge adjacent dome tops as suspended “ropeways,” which guide subsequent jet deposition and define pyramid arrises. As deposition continues and substrate thickness exceeds ~20 µm, domes evolve into prominent EMPAs; adjacent pyramids of similar height can fuse into larger pyramids as fiber accumulation increases. EMPA growth spans micron to millimeter scales.

Materials and structural designability: PVDF is used for proof-of-concept; other polymers (TPU, PVA) are also processed into EMPAs. Structural parameters are tuned by (i) electrospinning voltage (10.0–17.5 kV): pyramids appear, shrink, then vanish as voltage increases; 12.5 kV yields the largest unit size due to optimal fiber size and bead-to-string ratio; (ii) ambient humidity: higher relative humidity reduces charge density and pyramid size; (iii) syringe horizontal swing distance: controls deposition and substrate thickness, adjusting average pyramid height (APH). Films with large (3D EMPA-L), medium (3D EMPA-M), small (3D EMPA-S) APH and a flat electrospun film (2D EP) are prepared.

Device constructions: For piezocapacitive sensors and triboelectric nanogenerators (TENGs), devices comprise an Au-coated electrospun EMPA film (varying APH) paired with an Au-coated flat electrospun film. Piezoelectric nanogenerators (PENGs) use an in situ polarized electrospun PVDF film sandwiched between Au electrodes. An EMPA-based bilayer on-skin patch uses an EMPA layer and electrospun PVA nanofiber glue for facile lamination by humidification.

Imperceptibility assessments: Gas permeability is characterized by water weight loss through bottles covered with test films, comparing EMPA to conventional on-skin materials (Au-coated PDMS 300 µm, PET 120 µm, PI 50 µm). User perception is measured via a visual analog scale (VAS, 0–10) with 20 participants wearing either the ultrathin, ultralight EMPA bilayer device or a conventional PDMS-film-based bilayer (500 µm pyramidal PDMS plus polypropylene tape). Skin condition is photographed after 7 hours. Sensorimotor interference is tested with an object-grasping task: 18 participants grasp, lift, and hold an instrumented object of varying mass under three conditions (bare finger, EMPA device, PDMS device). Grip force is analyzed 2–3 s after lift-off; additional grip force (friction-adjusted) is computed; statistical comparisons include post hoc tests.

Radiative cooling measurements: Optical properties (vis–NIR reflectivity, MIR emissivity) of 2D EP, 3D EMPA-S/M/L are measured and related to the AM1.5 solar spectrum and the atmospheric transparency window. Daytime radiative cooling performance is tested under 1 kW m−2 solar intensity, recording sub-ambient temperature drops; on-skin cooling is evaluated by attaching 3D EMPA-L to skin under sunlight exposure for ~8 minutes and comparing with white and black cotton-containing fabrics.

Pressure sensing and bioenergy harvesting tests: Piezocapacitive sensors’ relative capacitance change versus pressure is measured, extracting low-pressure sensitivity (≤200 Pa) and higher-pressure behavior; detection limit and response time are characterized; durability is tested over 1000 cycles at 2.3 kPa. TENG outputs (transfer charge density, voltage, short-circuit current density) are measured under a 5 N impact for depolarized EMPA and 2D films; an enhanced TENG pairs a flat electrospun PA66 film (tribo-positive) with 3D EMPA-M to measure current density, voltage, transfer charge density, and energy conversion efficiency. PENG outputs (current density, voltage) are evaluated versus APH. Application demonstrations include powering a digital clock during mouse clicking, long-duration (>4 h) fingertip pulse monitoring on a driver, and hybrid sensing of finger manipulation using a combined piezocapacitive (Sensor I) and triboelectric (Sensor II) system attached to fingertip and mouse, respectively, with synchronous current and capacitance signals distinguishing click states and recording pulses.

- Fabrication: Single-step electrospinning self-assembly yields ultrathin (<50 µm), ultralight (~1.1 mg cm−2), gas-permeable EMPA films composed of bead-on-string micro/nanofibers; structural control via voltage, humidity, and syringe swing enables tunable average pyramid height and unit fusion.

- Imperceptibility: EMPA films exhibit very high water vapor transmission; Au-coated EMPA covers show rapid water weight loss (≈0.55 kg m−2 d−1). The EMPA bilayer device scores 1.25 on VAS (23% of PDMS device’s score), with 95% of participants reporting no impact on work/daily life. After 7 h wear, skin under EMPA remains normal, whereas PDMS causes wrinkling/whitening. In object grasping, grip and additional grip forces with EMPA match bare finger (p = 1.0), while PDMS significantly increases forces (all comparisons p < 0.001), indicating minimal sensory interference by EMPA.

- Radiative cooling: As APH increases from 0 to 24.75 µm, MIR emissivity rises from 51.1% to 76.3%, with vis–NIR reflectivity 94.7–97.9%. A 47 µm-thick 3D EMPA-L achieves a sub-ambient temperature drop of 3.86 °C under 1 kW m−2; on-skin, it cools skin by 4 °C compared with exposed skin, outperforming white cotton (1.6 °C) and avoiding heating observed with black cotton.

- Piezocapacitive sensing: EMPAs markedly enhance sensitivity via gradient stress concentration at pyramid tips. The highest low-pressure sensitivity is 19 kPa−1 (≤200 Pa) for the largest APH; above 200 Pa, 3D EMPA-M shows the highest sensitivity due to optimal geometry. Detection limit reaches 0.05 Pa (e.g., mosquito weight), response time ~48 ms for an 80% ΔC, and durability is stable over 1000 cycles at 2.3 kPa.

- Triboelectric nanogenerators: EMPA-based TENGs outperform flat electrospun films due to increased contact area from gradient space filling. 3D EMPA-M provides the highest outputs among EMPAs. An improved TENG using PA66 (tribo-positive) with 3D EMPA-M achieves current density 51.74 mA m−2, voltage 1300 V, transfer charge density 105.1 µC m−2, and energy conversion efficiency 42%; fingertip-mounted TENG powers a digital clock during mouse clicks.

- Piezoelectric nanogenerators: In situ polarized PVDF PENG outputs (current density, voltage) increase with APH due to stronger through-thickness strain gradients from EMPA geometry.

- Hybrid sensing and health monitoring: Long-duration (>4 h) fingertip pulse monitoring records full waveform features (P1–P5), outperforming a commercial photoplethysmograph that misses P2. A hybrid EMPA sensor (piezocapacitive Sensor I + triboelectric Sensor II) simultaneously tracks fingertip pulses and finger manipulation, distinguishing separation, light touch, presses, and click types. Sensor II’s ultrafast response (≤0.8 ms) corrects misidentifications from Sensor I during rapid multiple clicks; pulse signals remain stable after 550 clicks and two ~20 N presses.

The study demonstrates that self-assembled electrospun micropyramid arrays address the fundamental challenge of combining imperceptibility (ultrathin, ultralight, gas-permeable) with high functional performance in on-skin devices. EMPA’s gradient geometry enhances optical (high vis–NIR reflectivity, boosted MIR emissivity for radiative cooling), mechanical (localized stress concentration for sensitive pressure transduction), and electrical properties (enhanced triboelectric and piezoelectric outputs), directly translating into superior device performance while maintaining minimal sensory interference. User studies confirm that EMPA devices do not disrupt sensorimotor control in precision grip, unlike conventional thicker PDMS-based devices. The enhanced radiative cooling provides practical on-skin thermal comfort under sunlight. In sensing, EMPAs enable high sensitivity and ultralow detection limits for subtle biosignals (e.g., fingertip pulses) and, when combined with a fast triboelectric channel, capture rapid manipulation dynamics without compromising continuous pulse monitoring. The improved TENG and PENG outputs further indicate potential for self-powered systems. Overall, EMPAs bridge a gap in on-skin technologies by uniting advanced microstructured performance with breathable, imperceptible wearability.

The work introduces versatile, structurally designable EMPAs via electrospinning self-assembly, achieving ultrathin, ultralight, gas-permeable 3D micropyramid arrays from multiple polymers. These EMPAs empower on-skin devices with superior performance and imperceptibility across radiative cooling, pressure sensing, and biomechanical energy harvesting. Key contributions include a 47 µm EMPA radiative cooling fabric with 97.9% vis–NIR reflectivity and 76.3% MIR emissivity delivering ~−4 °C cooling under 1 kW m−2, piezocapacitive sensors with sensitivity up to 19 kPa−1 and 0.05 Pa detection limit, and nanogenerators with high triboelectric and piezoelectric outputs (e.g., 105.1 µC m−2 transfer charge density, 42% efficiency). Human studies validate exceptional imperceptibility with no measurable interference in grip control. Future work may optimize materials and microgeometry to further enhance outputs and sensitivities, integrate multimodal sensing and energy harvesting for fully self-powered systems, and expand applications in healthcare, human–machine interaction, and protective wear.

The paper does not include a dedicated limitations section. Observed constraints include: (i) piezocapacitive sensing shows slower response (~48 ms) leading to occasional misidentifications during very rapid multiple clicks, mitigated by the hybrid triboelectric channel; (ii) sensor sensitivity depends on pyramid geometry (APH), with trade-offs between low- and high-pressure ranges; (iii) EMPA formation is sensitive to processing parameters (voltage, humidity, deposition), which may affect reproducibility and scalability if not tightly controlled. Long-term durability on skin and environmental robustness beyond reported tests are not extensively discussed.

Related Publications

Explore these studies to deepen your understanding of the subject.