Engineering and Technology

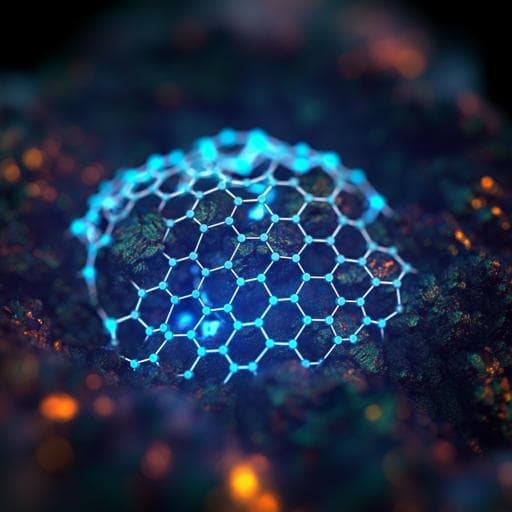

Transfer-free rapid growth of 2-inch wafer-scale patterned graphene as transparent conductive electrodes and heat spreaders for GaN LEDs

F. Xiong, J. Sun, et al.

Discover a groundbreaking transfer-free technique for growing high-quality patterned graphene directly on GaN LED epilayers, enhancing heat management in devices. This innovative method, developed by Fangzhu Xiong and colleagues, showcases exceptional efficiency and scalability.

Related Publications

Explore these studies to deepen your understanding of the subject.