Engineering and Technology

Structural multi-colour invisible inks with submicron 4D printing of shape memory polymers

W. Zhang, H. Wang, et al.

Explore the groundbreaking research by Wang Zhang and colleagues on submicron-scale 4D printing of shape memory polymers, unlocking time-responsive features in 3D structures. This innovative approach leverages new SMP photoresist achieving stunning high-resolution prints, with transformative applications in temperature-sensitive labels and anti-counterfeiting.

~3 min • Beginner • English

Introduction

The study investigates whether 4D printing of shape memory polymers can be extended to the submicron scale to enable tunable structural colors and responsive photonic elements. Conventional 4D printing methods (direct ink writing, PolyJet, DLP, SLA) are typically limited to ~10 µm feature sizes, which is too coarse for strong light–matter interactions required for structural color and optical devices. The authors aim to develop a two-photon polymerization (TPL)-compatible SMP photoresist and design robust submicron 3D photonic grid structures whose geometry and optical response can be programmed and recovered via the shape memory effect, thereby enabling large, rapid, and reversible color changes, akin to multi-color invisible inks revealed by heat.

Literature Review

Prior work in 4D printing has demonstrated stimuli-responsive structures for soft robotics, drug delivery, flexible electronics, and tissue engineering, primarily at micron-scale resolutions constrained by DLP and SLA. Structural colors have been realized using gratings, thin films, multilayers, and resonant nanostructures, typically yielding fixed colors. Dynamic color tuning has been achieved by modulating refractive index (e.g., liquid crystals, phase-change materials) or dimensions (mechanically reconfigurable plasmonic/dielectric systems). SMPs offer fast response times (seconds to minutes) and have been patterned via nanoimprinting and self-assembly, but these approaches limit design complexity. Recent TPL advances printed responsive hydrogels and liquid-crystal elastomers for tunable photonics, but color tuning ranges or stimulus types were limited (e.g., humidity or intrinsic LC periodicity). The gap remains for direct-write submicron 4D-printed SMP photonic structures enabling large, reversible color switching from colorless to vivid, with rapid recovery.

Methodology

Materials and photoresist preparation: A custom SMP TPL photoresist was formulated by first mixing 0.9 g 2-hydroxy-3-phenoxypropyl acrylate (HPPA) and 0.1 g Bisphenol A ethoxylate dimethacrylate (BPA) for 5 min, adding 20 mg diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide (TPO) and stirring for 1 h to form an elastomer resist, then blending with Stratasys Vero Clear at various mass fractions and stirring for 5 min. The mixture was stored at 22 °C in brown bottles.

Substrate preparation and TPL: Fused silica substrates (25×25×0.7 mm3) were cleaned in IPA ultrasound (2 min), baked at 120 °C (10 min), coated with TI PRIME (2000 rpm, 20 s), baked again (120 °C, 2 min). A drop of resist was patterned on a Nanoscribe Photonic Professional GT using a 63×, NA 1.4 oil immersion objective in Dip-in Laser Lithography. Laser power 30–40 mW and write speed 0.5–2 mm/s were used. Post-exposure development: PGMEA 5 min, IPA 2 min, DI water 1 min, N2 blow dry, followed by UV post-cure (365 nm, ~1 J/cm2, 10 min). Samples were relaxed 2 days to release residual stress.

Structure design: Square grid arrays atop a base layer: base thickness h1 ≈ 4 µm (set by fixed power 35 mW, 2 mm/s, 10 layers), grid pitch w2 ≈ 2 µm (chosen to balance saturation and avoid line fusion), tunable grid height h2 and linewidth w1 by varying write speed, laser power, and number of grid layers. Color palettes were printed by sweeping power (30–35 mW) and speed (0.6–1.1 mm/s); additional tests varied pitch (1–3 µm) at fixed nominal heights.

Programming (shape memory) protocol: Samples were heated above Tg (e.g., to 80 °C) and compressed by a metal block imposing ~500 kPa; while maintaining load, cooled to room temperature (~30 s) to fix a flattened, colorless temporary state. Recovery was triggered by reheating to 80 °C to restore original geometry and color within seconds. Additional controlled-pressure tests used a nanoimprint tool to apply up to 196 psi (~1351 kPa).

Characterization: Resolution and dimensions were assessed by SEM (JSM-7600F, 5 kV; Au sputter coat 60 s at 40 mA) and profilometry (KLA Tencor D-600; 0.01 mm/s, 1 mg stylus). Optical transmittance spectra were measured on a Nikon Eclipse LV100ND microscope with NA 0.2 (CA 11.5°), CRAIC 508 PV, normalized to fused silica. Refractive index was obtained by ellipsometry (ACCURION EP4) and fit with a Cauchy dispersion model. Thermomechanical properties were measured by DMA (TA Q800) in tension-film mode after erasing thermal history; uniaxial tensile tests at Tg+20 °C under 2 MPa/min. Rheology (TA DHR2) at 22 °C with 20 mm plate, freq. 10–4000 Hz. Numerical modeling used FDTD (Lumerical) with geometry from SEM/profilometry, plane-wave illumination from substrate side, near-to-far-field transform, and integration over the collection cone (NA 0.2) to compare with experiments.

Key Findings

- Submicron 4D printing of SMP achieved with TPL: minimum resolvable pitch ~600 nm (300 nm half-pitch) and linewidths down to ~280 nm, an order-of-magnitude finer than DLP/SLA for SMPs.

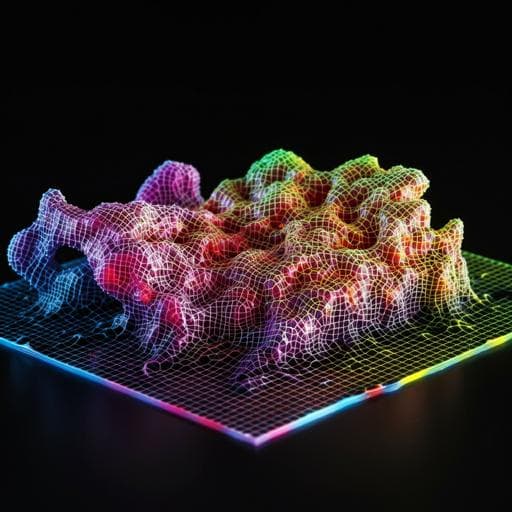

- Structural color generation with grid geometries: Color primarily tuned by grid height (h2) and linewidth (w1); base thickness h1 mainly affects phase. Optimal pitch w2 ≈ 2 µm (w2=1 µm caused line fusion and transparency; w2=3 µm reduced saturation).

- Dimensional control via process parameters: Increasing write speed (0.5→1.1 mm/s) reduced linewidth from ~630→285 nm and height from ~1990→980 nm at constant power; height increased ~100 nm per added layer, less than nominal 300 nm due to shrinkage.

- Optical response and simulations: Measured and FDTD-simulated transmittance spectra show qualitative agreement; resonance dips redshift with increasing h2 and with increasing w1 (simulated fixed h2=0.9 µm: w1 200→500 nm redshift ~450→600 nm). Near-field analysis indicates phase accumulation within grid lines and interference-driven focusing governing spectral features.

- Shape memory color switching: Flattening at T>Tg under ~500 kPa rendered structures colorless with high transmittance (~80%) across visible. Reheating to 80 °C restored geometry and original colors within seconds. Spectra before and after recovery are nearly identical with a small systematic blueshift.

- Repeatability and robustness: Multiple programming levels show progressive transparency with increasing flatness; recovered spectra were consistent over at least 4 programmed cycles and no obvious color change even after 10 cycles. Pressure threshold study: ~26 psi (~179 kPa) sufficient to erase color; ~196 psi (~1351 kPa) can cause irreversible edge collapse. Edge regions without supports are more susceptible to stiction-related irrecoverable damage.

- Demonstration: A 52×52-pixel (10 µm pixel) multi-color image was printed, erased to transparent, and fully recovered by heating, illustrating temperature-indicator labeling and anti-counterfeiting potential.

Discussion

The work demonstrates that submicron-scale 4D printing of SMPs is feasible using a custom Vero Clear–based TPL resist, enabling responsive photonic structures whose geometry and structural color can be programmed and rapidly recovered. This addresses the gap between conventional 4D printing resolution (~10 µm) and the subwavelength regime needed for strong optical effects. The grid design provides mechanical stability and tunable optical responses through controllable linewidth and height, corroborated by FDTD modeling of interference and far-field collection. The observed near-complete recovery in both microtopography and spectra after programming cycles highlights SMP suitability for reversible nanophotonic devices. The approach has significance for temperature-sensitive labels, information hiding/anti-counterfeiting, and tunable color filters. Remaining challenges include pushing resist resolution toward the TPL system limit, mitigating edge collapse and stiction, and enabling contactless actuation (e.g., by electrical, optical, or magnetic stimuli) alongside systematic microscale mechanical testing to relate stress–strain–temperature to optical performance.

Conclusion

Submicron-scale 4D printing of an SMP was realized by two-photon polymerization using a tailored Vero Clear–based photoresist, achieving ~300 nm half-pitch features and robust structural color generation. Colors are widely tunable via printing parameters (laser power, write speed, number of layers) that set grid linewidth and height. Programmed flattening above Tg erases color, while reheating rapidly and stably restores both geometry and optical response over repeated cycles. This platform enables multi-color invisible inks and responsive photonic elements relevant to optics and sensing. Future work should enhance resist resolution toward ~100 nm features, increase stiffness to reduce shrinkage and edge failures, explore contactless actuation methods, and conduct micro/nanoscale mechanical testing to fully map mechanical–optical coupling and extend cycling durability (e.g., via chemistries promoting π–π interactions and chain entanglements).

Limitations

- Current resist resolution, while high, does not yet match the ultimate capability of TPL systems; feature rounding and shrinkage occur, and layer height shrinkage (~100 nm realized vs 300 nm nominal) impacts accuracy.

- Edge regions of grids lack support and are prone to stiction-induced irreversible collapse under high compression, leading to dark corners and partial non-recovery.

- Printing proximity effects and resist shrinkage limit minimum practical pitch in multilayer grids (color saturation trade-offs at small/large pitches).

- Programming requires thermal and mechanical loading; implementation of contactless actuation was not demonstrated.

- Comprehensive in situ micro/nanoscale mechanical testing at controlled temperatures is pending to quantify stress–strain relationships and size effects; the number of durable program–recover cycles could be further increased with alternative chemistries.

- Minor spectral blueshift upon recovery suggests slight residual geometric changes.

Related Publications

Explore these studies to deepen your understanding of the subject.