Introduction

The burgeoning "Internet of Things" and the increasing popularity of flexible electronics, projected to reach a USD 56 billion market by 2026, highlight the need for continuous power sources for these devices. Energy harvesting technologies like triboelectric, piezoelectric, and flexible solar cells have been explored, but flexible thermoelectric generators (FTEGs) offer a unique advantage by directly converting body heat into electricity, eliminating the need for external energy sources or mechanical motion. However, current thermoelectric materials, including both inorganic (like bismuth antimony telluride alloys and silver selenide) and conducting polymers (such as PEDOT:PSS and PANI), are inherently inflexible. Previous attempts to create flexible FTEGs have focused on thin films or sheets, which primarily harvest energy in the in-plane direction, limiting efficiency. Three-dimensional (3D) FTEGs are more suitable for body heat harvesting, but existing approaches using rigid thermoelectric legs embedded in flexible matrices compromise comfort and reliability. Mixing insulating elastomers with conducting materials yields stretchable thermoelectrics, but these composites suffer from significantly lower thermoelectric performance compared to inorganic materials. This study aims to overcome this challenge by developing a highly elastic, high-performance 3D thermoelectric material.

Literature Review

The literature extensively covers the challenges and advancements in flexible thermoelectric generators. Bulk thermoelectric materials, while efficient, lack the flexibility required for wearable applications. Thin-film approaches improve flexibility but often limit energy harvesting to the in-plane direction. 3D designs integrating rigid legs into flexible matrices offer superior performance, but the bulkiness and rigidity compromise comfort and reliability. Polymer composites with conductive fillers offer stretchability but significantly lower performance. This research addresses the need for a material that effectively combines both high elasticity and high thermoelectric performance, filling a critical gap identified in previous studies on wearable energy harvesting technologies.

Methodology

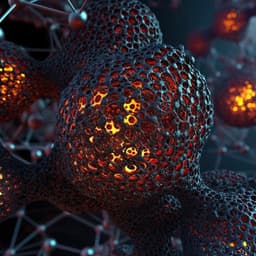

This research introduces a novel two-step impregnation method for synthesizing a 3D Ag₂Se network. The process starts with pre-treating a melamine foam template with SnCl₂. In the first step, the template is immersed in Tollens' reagent, reducing Ag⁺ ions to form a silver network. The second step involves impregnating the silver network in a selenium solution to in-situ synthesize the Ag₂Se network. The porosity of the resulting network can be controlled by adjusting reaction parameters. The entire process is conducted at ambient conditions, enabling large-scale production (nearly 2 square meters). The Ag₂Se network is characterized through various techniques including Archimedes method for porosity measurement, field emission scanning electron microscopy (FESEM) for morphology and energy dispersive spectrum analysis, X-ray diffraction (XRD) for crystal structure, a stress-strain apparatus for mechanical properties, and a ZEM-3 system for Seebeck coefficient and electrical resistivity. Thermal conductivity is determined using a hot wire method, and optical band gap is measured using Fourier transform IR reflectance spectroscopy. A finite element simulation in COMSOL was used to compare the temperature distribution of the network-based FTEG with both fully filled and partially filled bulk-based FTEGs. The output performance of the Ag₂Se network-based FTEG was evaluated experimentally and compared to simulations. A thermoelectric jacket was fabricated to demonstrate practical application, partially replacing the jacket's filler with FTEG modules.

Key Findings

The two-step impregnation method successfully created a 3D Ag₂Se network with remarkable properties. The network exhibits an elongation of >100% and a compressive strain of >80%, with a Young's modulus of approximately 0.03 MPa—a tissue-like modulus ideal for skin contact. Cyclic mechanical and electromechanical tests demonstrated good durability. The Ag₂Se network displays a Seebeck coefficient of -130 µV K⁻¹ and an ultralow thermal conductivity of 0.04 W m⁻¹ K⁻¹, leading to a high zT value of ~0.11—one or two orders of magnitude higher than previously reported 3D flexible thermoelectric materials based on polymer composites. Finite element simulations showed that the network-based FTEG established a significantly larger temperature difference (-6.5 K) compared to bulk-based FTEGs, while maintaining a hot-side temperature closer to skin temperature. Experimental results showed that a network-based FTEG attached to the arm achieved a power density comparable to high-performance bulk-based FTEGs. Furthermore, a thermoelectric jacket incorporating the Ag₂Se network generated milliwatt-level power, sufficient to power many wearable electronics. The method was successfully applied to various fabric substrates, demonstrating its versatility for creating personalized thermoelectric devices.

Discussion

The findings demonstrate that a highly flexible and efficient 3D thermoelectric material can be achieved using a scalable and cost-effective method. The superior performance of the Ag₂Se network-based FTEG compared to previously reported 3D flexible thermoelectric materials highlights the effectiveness of this approach. The ultralow thermal conductivity is a crucial factor, enabling a larger temperature difference without compromising skin temperature. The successful integration of the FTEG into a wearable jacket shows the potential for practical applications. The results advance the field of wearable energy harvesting by bridging the gap between flexibility and high thermoelectric performance.

Conclusion

This study successfully synthesized a 3D Ag₂Se thermoelectric network with exceptional elasticity and high thermoelectric performance through a scalable two-step impregnation method. The resulting FTEG demonstrates output power comparable to state-of-the-art bulk devices, while maintaining superior flexibility and comfort. The integration into a wearable jacket proves the practical application of this technology for powering wearable electronics. Future research could explore optimizing the network structure for further performance enhancement, developing compatible p-type materials for improved device efficiency, and exploring alternative electrode materials for better elasticity.

Limitations

While the study demonstrates promising results, there are limitations to consider. The current design of the FTEG module may be improved with optimized geometric factors. The contact resistance between the Ag₂Se network and the copper electrodes slightly reduces the observed output power compared to simulations. Further research is needed to explore alternative electrode materials and optimize the module design to maximize energy harvesting efficiency. The long-term durability of the device under various conditions warrants further investigation.

Related Publications

Explore these studies to deepen your understanding of the subject.