Engineering and Technology

Massively parallel electro-optic sampling of space-encoded optical pulses for ultrafast multi-dimensional imaging

Y. Na, H. Kwak, et al.

The study addresses the need for rapid, accurate, and high-dynamic-range surface profile imaging for micro- and nano-scale devices, both for static dimensional metrology and for observing fast, complex mechanical dynamics. Optical imaging and metrology underpin applications from on-chip vibration measurement and biomedical imaging to LiDAR. Existing tools such as interferometry and confocal microscopy face trade-offs between speed and measurement range for static profiling. For dynamic behaviour, coherent and white-light interferometers offer nanometric axial resolution but suffer from sub-micrometre ambiguity range and slow video-rate acquisition, missing motions on metre-per-second scales. Laser Doppler vibrometers provide high bandwidth but only single-point, out-of-plane motion, making full-field, real-time observation of nonlinear, transient, and nonrepetitive dynamics challenging. To fill this gap, the authors introduce a line-scan time-of-flight (TOF) camera leveraging electro-optic sampling (EOS) with a frequency comb to capture >1000 spatial points simultaneously with up to 260 megapixels/s pixel rate, sub-nanometre axial precision, several-millimetre field-of-view, and dynamic range up to 126 dB, enabling precise, high-throughput 3D imaging and real-time tracking of fast mechanical motions.

- Interferometric methods (coherent and white-light) provide nanometric axial resolution and reliability but are limited by sub-micrometre ambiguity range and slow video rates (few Hz), making them inadequate for fast motions.

- Confocal microscopy can achieve accurate profiling but at the cost of speed, with typical imaging of a 1024×1024 field taking hundreds of seconds; measurement range is typically below a few micrometres.

- Laser Doppler vibrometers offer very high bandwidth (up to GHz) but measure only single-point, out-of-plane vibrations, lacking full-field capability.

- Prior frequency-comb-based imaging using space-to-wavelength encoding suffered from low pixel counts and axial resolutions on the order of tens of micrometres due to degraded temporal confinement of sub-pulses. These limitations motivate a method that combines high speed, large field-of-view, high axial precision with long ambiguity-free range, and massively parallel full-field measurement.

The system is a frequency-comb-based, electro-optic-sampling line-scan time-of-flight (TOF) camera. Key components and processes:

- Source and spatial encoding: A mode-locked Er-fibre optical frequency comb (1537–1577 nm) is spectrally dispersed by a diffraction grating to achieve space-to-wavelength encoding. The beam incident on the grating is expanded to attain ~0.038 nm spectral resolution, yielding ~1000 resolvable sub-pulses across ~40 nm bandwidth, matched to a 1024-pixel InGaAs line-scan camera. After focusing (e.g., with f=30 mm lens), the dispersed sub-pulses form a line illumination ~9.5 µm wide and ~4.4 mm long across the sample; each sub-pulse corresponds to a lateral position and experiences a TOF determined by the local surface height.

- Electro-optic sampling detection (EOS-TD): Reflected sub-pulses are fed into an EOS-based timing detector implemented as a unidirectional phase modulator inside a differential-biased fibre Sagnac loop. A periodic electric waveform provides a timing ruler: either (i) the rising edge of photocurrent pulses from a high-speed modified uni-traveling carrier (MUTC) photodiode driven by the comb, or (ii) a frequency-locked VCO microwave signal. The EOS-TD phase-modulates the optical pulses relative to this timing ruler, converting TOF deviations into spectral intensity variations at the Sagnac output. Despite sub-pulse broadening (>90 ps due to spectral slicing), EOS still yields sub-nanometre precision.

- Spectral-to-TOF reconstruction: The spectrum at the EOS-TD output is captured by the 1024-pixel line-scan camera. Wavelength is mapped to position (x), and intensity encodes TOF at each position, allowing simultaneous recovery of TOF profiles for >1000 spatial points.

- Axial precision and measurable range tuning: The MUTC photodiode bias voltage adjusts the edge sharpness of the timing ruler, trading measurable range for sensitivity: at 4 V, 8 V, and 16 V biases the ranges are ~3.0 mm, 1.6 mm, and 1.2 mm, respectively (unsaturated camera). Camera saturation can further increase sensitivity at the cost of range (e.g., ~0.4 mm at 16 V with higher gain).

- Resolution characterization: Axial precision is evaluated via overlapping Allan deviation versus acquisition time, from the minimum camera exposure (3.9 µs, 260 MP/s) to multi-second averaging. Lateral resolution and field-of-view are measured using a USAF 1951 resolution target and beam profiling; with f=30 mm, the 1/e^2 beam width is ~9.5 µm and the line FOV exceeds 4.4 mm. A pair of f=60 mm lenses is also used for higher spatial resolution in complex-structure imaging.

- 3D imaging and metrology: 3D maps are generated by scanning the sample orthogonal to the line (Y direction) using a motorized stage, either synchronously (line acquired after motor settles for accuracy tests) or at maximum speed for throughput demonstrations. Step height accuracy is benchmarked against a calibrated interferometer (expanded uncertainty 40 nm, k=2) and confocal microscopy for complex structures. Repeatability is assessed over 100 repeated measurements at specified acquisition rates.

- High-speed scanning demonstration: Rapid scanning at 0.7 m/s generates a 6.4 mm × 2.4 mm 3D map (1024 × 882 pixels) in 3.47 ms, corresponding to 260 MP/s, implying >120 Hz full-HD-equivalent 3D frame rates when scaled to 1920 × 1080.

- Massively parallel TOF imaging: Simultaneous measurement of >1000 spatial coordinates across several mm FOV using frequency-comb EOS with space-to-wavelength encoding.

- Speed and precision: Pixel rate up to 260 megapixels/s (3.9 µs per line). With 16 V MUTC bias (unsaturated), axial precision is 155 nm at 3.9 µs; best precision reaches 580 pm at 2.6 s averaging (394 pixels/s). Dynamic range up to 126 dB calculated as 20 log(1.2 mm / 580 pm).

- Sensitivity-range tradeoff: Measurable ranges of ~3.0 mm (4 V), 1.6 mm (8 V), and 1.2 mm (16 V) in unsaturated operation. Under camera saturation (16 V, ~5× gain), range ~0.4 mm with improved precision: 47 nm at 3.9 µs and 330 pm at 0.87 s (~1.2 kpixels/s), maintaining ~122 dB dynamic range [20 log(400 µm / 330 pm)].

- Per-pixel precision: At 10 ms acquisition (~100 kilopixels/s) and 16 V bias, axial precision varies with spectral intensity from ~3.5 nm to ~7.4 nm across pixels.

- Lateral performance: Beam width ~9.5 µm (1/e^2) and line FOV >4.4 mm with f=30 mm. USAF target yields lateral resolution ~114 lp/mm (~4.38 µm) at ~23% contrast.

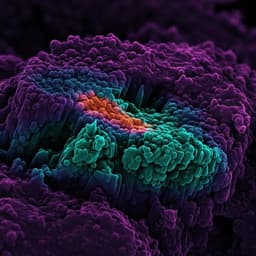

- Accurate step metrology: Same-material 300 µm step measured as 300.029 µm with 31 nm repeatability (100 measurements at 10 kHz line-scan), +31 nm error vs calibrated interferometer (299.998 µm). Different-material steps (steel blocks on ceramic): 100 µm and 500 µm steps with 86 nm and 93 nm repeatability at 10 kHz; errors +15 nm (100.014 µm ref) and −22 nm (500.060 µm ref). Periodic silicon/silver structure: mean step 10.039 µm, within 14 nm of confocal (10.053 µm).

- Throughput: High-speed 3D mapping of a 6.4 mm × 2.4 mm area at 1024 × 882 pixels in 3.47 ms (260 MP/s), corresponding to >120 Hz frame-rate potential for full-HD 3D profiles.

The presented line-scan TOF camera directly addresses the need for real-time, high-dynamic-range, full-field surface imaging of micro- and nano-scale devices. By combining space-to-wavelength encoding with EOS-based timing detection, the system overcomes the pixel-count and axial-resolution limitations of previous frequency-comb imaging and the range/speed trade-offs of interferometric and confocal methods. The capability to achieve sub-nanometre axial precision with several-millimetre measurable range, multi-megapixel-per-millisecond throughput, and few-micrometre lateral resolution enables both accurate static dimensional metrology and real-time observation of fast, nonrepetitive mechanical motions that are inaccessible to stroboscopic or single-point techniques. The successful validation against calibrated interferometry and confocal microscopy demonstrates metrological accuracy, while the demonstrated >120 Hz 3D frame-rate potential indicates practical viability for high-throughput industrial inspection and dynamic studies of complex mechanical phenomena. The results suggest broad relevance across MEMS/3D-IC metrology, optomechanics, phononics, and sensing, where capturing transient and nonlinear dynamics with high fidelity is crucial.

The work introduces a new class of electro-optic-sampling-based line-scan TOF camera that achieves a unique combination of performance: simultaneous acquisition of >1000 spatial points, up to 260 megapixels/s pixel rate, sub-nanometre axial precision (down to 330 pm), multi-millimetre measurable range, up to 126 dB dynamic range, and ~4.4 µm lateral resolution over millimetre-scale FOV. It enables fast, accurate 3D surface profiling and precise step-height metrology across disparate materials, and real-time imaging of complex, fast mechanical dynamics. Future directions include: (i) employing faster line-scan cameras to fully exploit the EOS-TD’s per-pulse readout capability; (ii) implementing vibration-free, high-speed lateral scanning (e.g., acousto-optic deflection) to replace mechanical stages; (iii) optimizing spectral power uniformity to equalize per-pixel precision and dynamic range; and (iv) further integration and stabilization to mitigate slow thermal and timing drifts for long-term precision.

- Precision non-uniformity across pixels due to non-uniform optical spectrum; dynamic range and precision vary with spectral intensity.

- Trade-off between sensitivity and measurable range: higher MUTC bias and camera saturation improve precision but reduce range (e.g., down to ~0.4 mm when saturated at 16 V).

- Long-term averaging limited by slow timing drifts (thermal fiber length mismatch, comb power drift, timing drift between optical and electrical ruler), which cap precision improvements at long acquisition times.

- Edge ambiguity in TOF at discontinuities where multiple reflections occur (e.g., gauge block edges).

- Current high-speed 3D scans rely on mechanical stages; stepwise scanning and motor vibrations necessitate synchronization for accurate metrology; true vibration-free, continuous high-speed scanning not yet implemented.

- SNR limited by camera background (white noise), setting per-pixel precision bounds.

Related Publications

Explore these studies to deepen your understanding of the subject.