Chemistry

Lamellar carbon nitride membrane for enhanced ion sieving and water desalination

Y. Wang, T. Lian, et al.

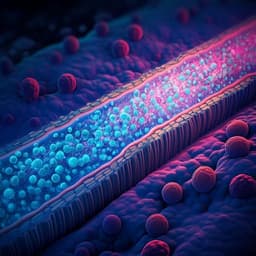

The study addresses a key challenge in 2D-material membranes for desalination: swelling and structural disintegration in aqueous environments that compromise precise ion and molecular sieving. While 2D materials like graphene oxide and MXenes show promise, their hydrophilic oxygen-containing groups often cause uncontrolled swelling and defects, especially under high normal and swelling forces in subnanometer channels. Polymeric carbon nitrides (CN, often termed g-C3N4) are chemically and thermally stable and, when exfoliated, could in principle resist interlayer swelling. However, conventionally assembled CN membranes restack randomly, wrinkle under filtration pressure, and exhibit defects that allow non-selective ion transport, contradicting the expected subnanochannel sieving based on their ~3.2 Å layer spacing. The research question is whether CN layers can be engineered into a conformally packed lamellar membrane with activated, stable subnanometer channels that provide high water flux with high ion rejection and resist swelling, and whether such membranes can maintain performance under varying pH conditions. The authors propose activating and stabilizing CN interlayers by intercalating highly charged aluminum Keggin polycations as pillars to create adaptive subnanochannels and a robust lamellar architecture for precise ion sieving and desalination.

Prior works show 2D membranes can enable precise sieving via interlayer channels/intralayer pores in the subnanometer regime and support unusual nanofluidic phenomena. Graphene oxide and MXenes have been applied to desalination and purification but typically swell or disintegrate in aqueous/organic media. For CN-based systems, various fabrication routes (microwave-assisted condensation, microcontact printing, CVD, liquid-based and direct growth) produced films for photoelectrochemical and ion diffusion tests, and filtration assemblies removed large dyes/pollutants and nanoparticles in ultrafiltration/nanofiltration, sometimes leveraging photocatalysis. In reverse/forward osmosis, CN nanosheets mostly served as fillers or modifiers in thin-film composites rather than as the active lamellar membrane. Conventional CN membranes exhibit random restacking and wrinkling, hindering intercalant access to interlayers and preventing controlled subnanochannel formation; as a result, reported CN membranes often show permeability to salts inconsistent with nominal gallery heights and block only larger solutes. Earlier use of acid spacers or partially exfoliated CN improved flux but did not establish robust, non-swelling subnanometer channels that deliver simultaneous high salt rejection and water flux in FO. These gaps motivate the present pillaring strategy using aluminum polycations to both activate and lock interlayer channels.

Materials and synthesis:

- CN (polymeric carbon nitride) was synthesized by thermal condensation of melamine: 5 g melamine heated in a lidded crucible at 550 °C for 4 h (ramp 2.3 °C min−1) in air; product ground to yield bulk CN. Exfoliation: 200 mg bulk CN sonicated in 200 mL water for 12 h (ultrasonic bath, 90 W), centrifuged (2375 × g, 10 min) to remove large flakes; supernatant aged 3 days; final supernatant used as CN nanosheet dispersion.

- Keggin Al13 and Al30 polycations: Prepared by controlled hydrolysis of AlCl3·6H2O with NaOH at 60 °C (Al13) or 95 °C (Al30), pH controlled; stirred 12 h and aged 24 h at respective temperatures; [OH]/[Al] = 2.4, [Al] = 0.2 M; solutions stored 5 days before use. Speciation analyzed by Al–Ferron kinetics (UV-vis at 363 nm).

Pillared composite preparation (powders):

- CN dispersion added dropwise into Al13 or Al30 solutions at mass ratios 0.25:1, 1:1, 2:1, 4:1 (denoted ACN-1, -2, -3, -4 for Al30; analogous for Al13-CN). Mixing under vigorous stirring at 60 °C (Al13) or 95 °C (Al30) for 12 h; aged 24 h. Suspension centrifuged (7700 × g, 15 min); precipitate washed by vacuum filtration (AgNO3 test to remove Cl−); dried under vacuum at 20, 60, or 100 °C for >15 h.

Membrane substrates and assembly:

- Substrate: Polydopamine (PDA)-coated polyether sulfone (PES) filters (25 mm, 0.2 µm pores, 125 µm thick). PDA coating: dopamine chloride (2 mg mL−1) in 10 mM Tris–HCl (pH 8.5); immerse PES 24 h; rinse and bake 60 °C under vacuum. Bare PDA-PES shows no water flux but high salt permeation in FO, thus not limiting performance evaluation.

- CN membranes: CN nanosheet supernatant further centrifuged (7700 × g, 15 min); supernatant diluted and vacuum-filtered onto PDA-PES to target thicknesses 350, 500, 740, 1500 nm; dried 60 °C under vacuum >15 h.

- ACN membranes: Supernatant of Al30–CN suspension (after aging) collected (7700 × g, 15 min), diluted and vacuum-filtered onto PDA-PES to thicknesses 320, 500, 720, 1500 nm. In situ washing on the filtration setup with water to remove residual chloride (checked by 0.5 M AgNO3). Dried under vacuum at 20, 60, or 100 °C for >15 h.

Characterization:

- XRD to monitor interlayer spacing and free spacing changes (drying at 20/60/100 °C; drying–wetting cycles; wet versus dry). HR-TEM and TEM for lamellar morphology and fringe spacing; SEM cross-sections for layering; AFM for surface roughness and homogeneity; zeta potential for surface charge; FT-IR for CN and Al30 signatures and O–H bands; XPS depth profiling (argon ion sputtering to ~200 nm). 1H CP/MAS ssNMR to probe OH/water environments under varying pH.

Membrane stability tests:

- ACN membranes (60 °C dried) immersed 24 h in water; XRD recorded after wiping surface. Repeat drying–wetting cycles (3 cycles). Stability also tested after immersion in 0.2 M salt solutions (KCl, NaCl, CaCl2, MgCl2), acidic (pH 2) and alkaline (pH 12) solutions. Membranes dried at 20 °C detached and disintegrated in water; 60 °C and 100 °C dried membranes remained intact even after one month.

Ion permeation tests:

- H-shaped cell with two compartments (effective membrane area 0.785 cm2); membrane clamped between silicone gaskets (1 cm diameter opening). Feed: 50 mL of 0.2 M salt (KCl, NaCl, LiCl, CaCl2, MgCl2, unless otherwise noted); permeate: 50 mL water; both sides stirred. Permeate conductivity monitored (MultiLab 540); permeation rate P calculated from conductivity-to-concentration conversion and cell geometry over 24 h. Concentration dependence up to 2 M NaCl tested; reversibility assessed by decreasing concentration. Synthetic seawater feed used to assess mixed-ion rejection.

Forward osmosis (FO) water flux and salt rejection:

- Same H-cell; feed: 0.1 M NaCl; draw: 2 M sucrose (π ≈ 49 bar by van’t Hoff). Both sides stirred. Water flux J from liquid height change versus time; salt rejection R = 1 − Ca/Cf (Na+ at draw quantified by ICP-OES for pH-varied tests). pH of feed adjusted to 2 or 12 with 1 M HCl or NaOH for gating studies; neutral water pH ~5.7. Effect of membrane thickness and of thinner PES support assessed. Long-term FO up to 72 h conducted.

Computations:

- DFT (CP2K) with PBE-GGA, D3 dispersion, GTH pseudopotentials, DZVP-MOLOPT-SR-GTH basis, 400 Ry cutoff, spin-polarized; full geometry optimization (forces < 4.5×10−4 Ha/bohr). Adsorption energies of Keggin ions on CN computed; Fukui indices calculated to identify reactive sites. Structural model reflects polymeric CN with hydrogen-bonded tri-s-triazine chains, not idealized g-C3N4.

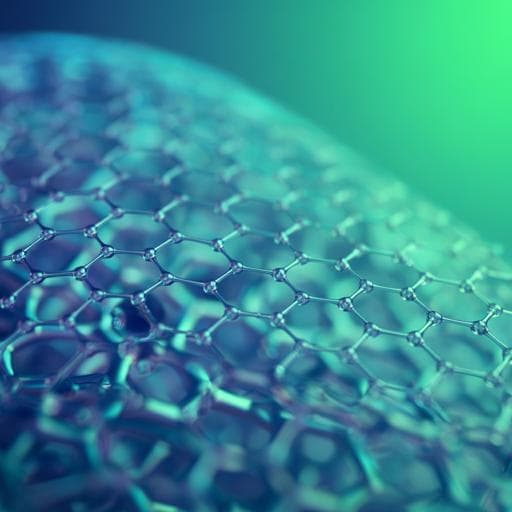

- Pillaring and interlayer activation: Al30 intercalation expands CN interlayer spacing from ~3.2 Å to ~9.8 Å (XRD), yielding free spacing ~6.6 Å at 20 °C in powders. Membrane free spacing contracts upon drying: ~6.3 Å (20 °C), 5.6 Å (60 °C), 5.3 Å (100 °C). Hydrated membranes show stable free spacing 5.6–5.9 Å with minimal swelling across drying–wetting cycles.

- Morphology: ACN forms conformally packed lamellar membranes with low roughness and homogeneous layering, unlike pristine CN which shows random particle-like restacking and heterogeneity that risks cracking on scale-up.

- Surface charge and interactions: Zeta potential demonstrates CN’s negative charge is neutralized and becomes net positive at higher Al30 loadings; FT-IR confirms CN–Al30 coexistence, with diminishing O–H vibrations with elevated drying temperature, indicative of removal of weakly bound water and retention of bound water within channels.

- Ion permeation (H-cell, ~720–740 nm membranes): Pristine CN shows high Na+ permeation (1.64 mol m−2 h−1; ~1.39 mol m−2 h−1 even when thickness doubled), and similarly high rates for K+, Li+, Ca2+, Mg2+ (1.39–1.93 mol m−2 h−1), indicating non-selective transport via defects. Al13–CN behaves similarly to CN. ACN membranes (with increasing Al30) progressively reduce Na+ permeation to 3.14×10−3 mol m−2 h−1 (ACN-3) and stabilize for ACN-4. For ACN-3, monovalent ions (K+, Na+, Li+) fall to ~10−3 mol m−2 h−1; divalent ions (Ca2+, Mg2+) fall to ~10−4 mol m−2 h−1, consistent with size exclusion by ~5.9 Å hydrated-channel spacing and higher dehydration barriers.

- Activation energies for ion permeation (Arrhenius analysis): K+ 11.5 kJ mol−1; Na+ 13.7 kJ mol−1; Li+ 13.1 kJ mol−1; Ca2+ 41.8 kJ mol−1; Mg2+ 44.8 kJ mol−1, supporting reduced likelihood of divalent ion entry into subnanometer channels.

- Mixed-ion feeds: Using synthetic seawater, ACN reduces ion permeation rates by ≥100× compared to CN in a highly saline environment. Na+ permeation varies linearly with feed concentration up to 2 M and is reversible upon concentration reduction, indicating stability.

- Forward osmosis performance (feed 0.1 M NaCl; draw 2 M sucrose): CN water flux averages 0.74 L m−2 h−1 and declines over time due to defect-mediated co-transport of NaCl/sucrose decreasing osmotic driving force. ACN membranes show steady water flux over time; increasing Al30 improves flux while suppressing NaCl passage, breaking the permeability–selectivity trade-off. An optimized 500 nm ACN-3 achieves water flux 3.0 L m−2 h−1 with 99.4% NaCl rejection; with improved support (thinner PES), flux increases further, reaching up to ~6 L m−2 h−1 with ~99.5% rejection. Over 72 h, ACN-3 shows <10% flux decline and <2.8% rejection loss.

- pH-tunable water gating: Water flux is higher at pH 12 than pH 2, with water gating ratios ~2.6 (320 nm thick) and ~2.3 (500 and 720 nm). NaCl permeation slightly increases at both pH 2 and 12, but rejection remains >95%. 1H CP/MAS ssNMR indicates stronger hydrogen bonding and trapped water at pH 2 (hindering flow), while at neutral/alkaline conditions water becomes more mobile; at pH 12, partial deprotonation/hydrolysis of Al30 and reduced negative charge enhance Na+ partitioning.

- Overall, ACN membranes exhibit high salt rejection (≥95% generally; ~99.4–99.5% under optimized FO) with high water flux (up to ~6 L m−2 h−1) and strong anti-swelling stability (hydrated free spacing 5.6–5.9 Å).

By intercalating highly charged Al30 polycations between CN layers, the authors convert randomly restacked CN nanosheets into a conformally packed lamellar membrane with activated, subnanometer transport channels. This addresses the central problem of swelling and defect-dominated transport in conventional 2D membranes by locking interlayers via noncovalent, cooperative interactions that stabilize free spacing near 5.6–5.9 Å under hydration. The resulting channels enable size-selective sieving that largely excludes hydrated ions, particularly divalent species with high dehydration barriers, while maintaining rapid water transport. The ACN membranes thus surpass the typical permeability–selectivity trade-off in forward osmosis, delivering both high water flux and high NaCl rejection, and maintain performance over extended operation and in acidic/alkaline environments. The pH-tunable water gating behavior is rationalized by changes in hydrogen bonding and water mobility within the channels and by Al30 protonation state, suggesting additional control knobs for process optimization. The robust lamellar architecture and nanoconfinement could enable future integration of CN’s semiconductor properties for membrane reactors coupling separation with catalysis.

The study demonstrates a practical strategy to engineer polymeric carbon nitride into stable lamellar membranes with activated subnanometer channels by pillaring with Al30 polycations. These ACN membranes resist swelling, provide conformal packing, and deliver high-performance ion sieving with water desalination in forward osmosis, achieving up to ~6 L m−2 h−1 water flux with ~99.5% NaCl rejection, and maintaining stability over time and across pH extremes. This work expands the functional 2D membrane library and suggests that carbon nitride’s photoactive properties could be exploited in future membrane reactors that integrate separation and catalysis. Future research could explore alternative pillaring chemistries, long-term fouling resistance, scalability and module integration, optimization of support layers to minimize internal concentration polarization, and coupling with photochemical functionalities for reactive separations.

- Membranes dried at 20 °C under vacuum detached and disintegrated upon contact with water, indicating the need for post-drying at ≥60 °C to ensure stability.

- Under extreme pH (2 or 12), partial hydrolysis or protonation changes of Al30 occur, slightly increasing NaCl permeation and reducing rejection (though still ≥95%).

- Reported maximum FO flux depends on support-layer properties (e.g., thinner PES improves flux), indicating sensitivity to internal concentration polarization and module configuration.

- The approach relies on specific Al30 polycations; broader chemical compatibility and long-term chemical stability of the pillars under diverse waters (e.g., chelators, natural organic matter) were not fully assessed.

- Scale-up considerations such as mechanical robustness under pressure-driven processes, and performance under realistic foulants, require further evaluation.

Related Publications

Explore these studies to deepen your understanding of the subject.