Engineering and Technology

High strength bio-concrete for the production of building components

M. Smirnova, C. Nething, et al.

The study addresses the challenge of producing MICP-based bio-concrete with compressive strengths comparable to conventional Portland-cement-based concrete while achieving sufficient cementation depth. Cement production contributes 7–8% of global CO2 emissions, and process emissions from clinker calcination persist even with renewable energy. MICP uses ureolytic bacteria to catalyze calcium carbonate precipitation, potentially yielding a CO2-negative binder. However, limitations in solute transport, bacterial retention, reactant depletion, and clogging often result in inhomogeneous cementation and limited depth. The research investigates whether using urease-active calcium carbonate powder (UACP), maximizing aggregate packing density, and employing a stop-flow pressure-based injection can enable high-strength, homogeneously cemented bio-concrete suitable for structural components.

Prior work has shown compressive strength in MICP-treated materials correlates with precipitated CaCO3 content but is limited by reactant solubility, bacterial transport, and flow-induced inhomogeneity. Percolation-based methods can suffer from near-inlet clogging and chemical depletion along flow paths. Embedding bacteria in CaCO3 (“bioslurry”) improves bacterial retention, and UACP enables long-term storage and activity retention during percolation. Earlier bio-brick and bio-concrete studies reported relatively low UCS (≈1–10 MPa), and even with UACP in fine sands UCS values around 23 MPa have been reported. Key gaps remain in achieving both high strength and substantial cementation depth with homogeneity. This study builds on those findings by optimizing aggregate packing and employing controlled pressure-driven, cyclic (stop-flow) cementation.

- Materials and UACP: Sporosarcina pasteurii DSM33 cultured (30 °C, 24 h) in peptone-based medium with urea. UACP prepared per Cheng & Shahin by mixing bacterial suspension with 0.4 M CaCl2 and 0.4 M urea to embed cells in CaCO3, then filtered and freeze-dried (~50 g UACP per liter culture). Urease activity quantified by NH4+ release assays.

- Aggregate packing optimization: Six quartz sand fractions (0.063–2.0 mm, density 2.65 g/cm³) were combined using EMMA software with the Modified Andreassen model to maximize packing density (fines excluded to maintain flow). Packing characterized by φaggr (voids between aggregates as if no UACP) and φaggr+UACP (initial pores free of both aggregates and UACP). Compaction at 5 N/mm² (and later 10 N/mm²) in layers.

- Mix preparation and compaction: Optimized sand mix pre-moistened with 10% (w/w) low-concentration cementation solution to prevent segregation; UACP dosed at 0.5–7.5% (w/Wdm). Mixing in a kneader (2+2 min) with manual scraping. Layer-wise compaction in cylindrical formworks (initially POM, later PVC pipes) at 5 or 10 N/mm²; layer surfaces roughened to improve interlayer adhesion.

- Automated stop-flow cementation: A custom system supplied one pore volume of cementation solution every 4 h from bottom to top under controlled pressures (0.1–1.0 bar). Most tests used 0.75 M equimolar urea and CaCl2; some used 1.25 M or 1.5 M. Six specimens cemented in parallel. Effluent collected on load cells to quantify flow; weights of specimens recorded via a descending-lifting device to mitigate load cell creep. Flow rates derived from effluent weight-time data.

- Experimental design: Test series 1–5 screened UACP content (0.5–7.5% w/Wdm), cementation solution concentration (0.75, 1.25, 1.5 M), and supply pressures (0.1–0.75 bar). Series 6 tested reproducibility using parameters of a best-performing case. Series 7 increased compaction pressure (10 N/mm²; higher packing) and explored step-wise pressure increases (0.1→0.4→0.7→1.0 bar at ~24/44/64 h) versus constant 0.1 bar.

- Analytical methods: Effluent NH4+, Ca2+, and urea quantified by photometric assays. Ultrasonic wave velocity (UWV) measured along specimen height (DIN EN 12504-4, DIN EN 14579). UCS testing used cylinders (D≈50–53.3 mm; H:D = 1:1 for inhomogeneous specimens; 2:1 for homogeneous in Series 7) with constant displacement rate (0.5 mm/min). CaCO3 content determined by pressure-calcimeter method. ESEM performed on epoxy-impregnated, polished cross-sections (top/middle/bottom) using Zeiss EVO LS15.

- Packing density optimization: The optimized sand grading achieved φaggr ≈ 0.35 at 5 N/mm² with 1.5% UACP, versus φaggr ≈ 0.45–0.47 for single-size fractions. Fines would reduce pore volume further but blocked flow in stop-flow injection and were excluded.

- Transition to pressure-based stop-flow: Gravity percolation with 18 cycles yielded <40 mm cementation depth and poor reproducibility. Automated pressure injection markedly improved depth and control.

- Full-height specimens and parameter effects (Series 1–5): Fully cemented specimens (H ≈ 135 mm) were achieved with: 0.5% UACP at 0.1 bar; 1.0% UACP at 0.1 bar; 1.5% UACP at 0.5–0.75 bar; and 7.5% UACP at 0.1 bar (reduced strength). Increasing supply pressure increased cementation depth for a given UACP content, but too high flow/pressure reduced density and strength. Clogging ultimately drove flow to near zero in all series; some specimens clogged from the outset under certain combinations.

- Strength: Maximum local UCS reached 57.4 MPa (specimen 5.6, lower part). Homogeneous specimens 7.1 and 7.2 reached UCS 51.2 MPa and 52.5 MPa with 140 mm height at φaggr ≈ 0.34 (compaction 10 N/mm², 0.1 bar constant), densities 2.20–2.22 g/cm³, and high UWV (≈4.38–4.90 km/s). Series 7 with step-wise pressure increases (7.3–7.6) had lower densities (2.13–2.15 g/cm³) and UCS (33.0–36.2 MPa), indicating high flow rates negatively affected strength.

- Chemical utilization and effluents: For 2.0–5.0% UACP, effluent urea and Ca2+ were near zero from early cycles, with NH4+ reaching 1.5 M (theoretical max for 0.75 M urea). For 0.5–1.5% UACP, effluent urea/Ca2+ initially detected then decreased over ~40–48 h; in some cases later increases suggested declining urease activity.

- CaCO3 content and porosity: Final CaCO3 contents measured 15–22% (w/w) across selected specimens. Estimated porosity decreased during cementation; flows approached zero when porosity reached ≈0.25. Inclusion of additional fines previously raised packing but prevented flow under 0.1 bar.

- Homogeneity and UWV: UWV correlated with local UCS. Specimen 1.2 showed highly homogeneous UWV (4.50–4.64 km/s); 5.3 slightly less but still high (4.31–4.64 km/s). Series 6 exhibited more variation than specimen 1.2 due to slightly lower packing; changing to PVC formworks and higher compaction (Series 7) improved homogeneity.

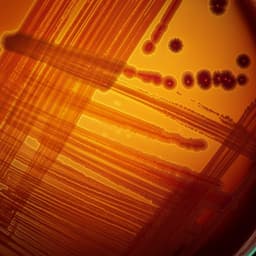

- Microstructure (ESEM): Quartz grains were uniformly coated by a CaCO3 layer ≈20 µm thick; denser coatings observed in mid-height sections than at top/bottom, likely due to local UACP availability and contact with formwork voids.

- Mechanical behavior: Stress–strain curves (Series 7) showed a plastic region near ~4 MPa followed by elastic response up to failure; estimated Young’s modulus ≈11–12 GPa. UCS increased exponentially with specimen density and correlated with UWV.

The study demonstrates that combining UACP, optimized aggregate packing, and automated stop-flow injection overcomes key barriers to producing high-strength, deep, and homogeneous bio-concrete. Maximizing aggregate content increases density and leverages the inherently stronger aggregates relative to CaCO3 bonds, thereby improving UCS. Controlling flow rates and pressures is critical: higher pressures can extend cementation depth by delivering reactants further into the specimen but excessive flow reduces density and strength, likely by limiting residence time and promoting nonuniform precipitation. The observed porosity threshold (~0.25) at which flow ceases indicates an intrinsic limit to permeability during cementation; higher initial packing necessitates higher supply pressures to maintain flow. Microstructural observations of a consistent CaCO3 coating thickness (~20 µm) suggest a growth limit at grain surfaces under the tested kinetics; more uniform UACP distribution could further improve homogeneity. Mechanical characterization places the material among porous ceramics, with modulus below conventional concrete; incorporating coarser aggregates could increase stiffness for structural applications. The method showed good reproducibility when packing density and pressures were controlled. Environmental and durability considerations (e.g., ammonium and chloride management, reinforcement corrosion when using CaCl2) must be addressed via raw material selection and effluent recycling strategies. Overall, the findings substantiate the feasibility of prefabricated, load-bearing bio-concrete components, provided process controls on compaction and flow are implemented.

Homogeneously cemented bio-concrete specimens were produced using an optimized sand grading (0.063–2 mm), UACP, and automated stop-flow pressure injection. With high packing density (φaggr ≈ 0.34) and controlled low supply pressure (0.1 bar), specimens reached 140 mm height with UCS of 51.2–52.5 MPa (and up to 57.4 MPa locally), exceeding prior reports. Strength and homogeneity depended strongly on aggregate packing and flow rate control; excessive flow reduced density and UCS, and permeability dropped as porosity approached ~0.25. The results indicate bio-concrete’s potential to partially replace conventional concrete in prefabricated, load-bearing components. Future work should: (i) refine mix design with coarse aggregates and selected fines (with appropriate pressure control) to enhance stiffness and packing; (ii) develop precise flow/pressure control strategies for upscaling; (iii) address reinforcement compatibility (e.g., corrosion-resistant fibers) and (iv) implement sustainable sourcing and effluent recycling to minimize environmental impacts.

- Homogeneity and strength are sensitive to packing density and flow rate; step-wise pressure increases led to higher flow rates and reduced UCS in some cases (Series 7).

- Clogging limits permeability as porosity approaches ~0.25, constraining processing unless higher supply pressures are used; inclusion of fines further impedes flow at low pressure.

- Some specimens exhibited inhomogeneous UCS along height (Series 1–5), indicating transport and kinetic limitations under certain parameter sets.

- Mechanical stiffness (E ≈ 11–12 GPa) remains lower than typical Portland-cement concretes; structural applications may require coarser aggregates and/or reinforcement.

- Environmental constraints include energy-intensive urea production and the need to manage/recycle ammonium- and chloride-rich effluents; CaCl2 use may be incompatible with steel reinforcement due to corrosion risk.

- Practical issues such as specimen removal from formworks (causing cracks under high extraction forces) required procedural modifications (PVC formworks).

Related Publications

Explore these studies to deepen your understanding of the subject.