Engineering and Technology

High-performance hybrid nanogenerator for self-powered wireless multi-sensing microsystems

D. Wen, P. Huang, et al.

This groundbreaking research presents a high-performance triboelectric-electromagnetic hybrid nanogenerator (TEHNG), capable of powering wireless multi-sensing microsystems. With a remarkable load power of 21.8 mW, this innovative system integrates various sensors to transmit real-time data, showcasing vast potential for IoT applications. Conducted by Dan-Liang Wen, Peng Huang, Hai-Tao Deng, Xin-Ran Zhang, Yi-Lin Wang, and Xiao-Sheng Zhang.

~3 min • Beginner • English

Introduction

Wireless sensor network nodes that integrate power, diverse sensing, communication, and other functional components are essential components of the Internet of Things (IoT), which is developing rapidly with the gradual popularization of fifth generation mobile communication technology (5G) and the continuous breakthrough of electronic information technology. Conventional lithium batteries and nickel-zinc batteries, which are currently the most commonly used power supply units for industrial and wearable electronic devices, offer critical drawbacks such as frequent charging (or disposable devices), poor flexibility, and environmental pollution. Such equipment no longer satisfies the increasing requirements of portable power sources capable of advancing the rapid development of IoT. Therefore, the development of reliable portable power sources to overcome the above challenges is of great importance for further advancement and widespread applications of industrial electronics and wearable electronic devices, making this space an attractive research field.

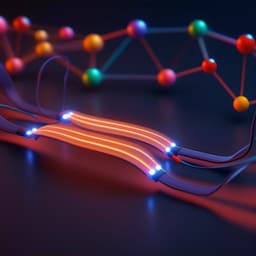

In recent years, an emerging technology for mechanical vibration energy harvesting based on the coupling of the triboelectric effect and electrostatic induction, namely, triboelectric nanogenerators (TENGs), have been proposed and have experienced vigorous development. TENG has been proven to offer many advantages, such as excellent sustainability, high output performance, simple preparation process, and diverse material selection. Therefore, it is a reliable and efficient approach to address the sustainable power supply issue of industrial and wearable electronic devices, and it has been widely applied to realize self-powered sensors, self-powered actuators, self-powered microsystems, and so on. However, energy harvesters based on a single triboelectric mechanism present low conversion efficiency of mechanical energy. Thus, methods have been developed to improve it, such as introducing high-performance materials, processing surfaces with micro-structures, studying/compositing energy conversion mechanisms, and improving energy transfer efficiency. Nevertheless, hardly any completely self-powered real-time continuous wireless multisensing microsystem have been demonstrated due to the insufficient load power capability of the energy harvester.

In this work, to realize a completely self-powered real-time continuous wireless multisensing microsystem, we develop a high-performance triboelectric-electromagnetic hybrid nanogenerator (TEHNG) based on a circular spring-cantilever structure. The optimized triboelectric pair of polyvinyl chloride (PVC) and polydimethylsiloxane (PDMS) was selected after experimental investigation. The configuration of the copper coil and magnet for the electromagnetic part was optimized by comparing magnets with different diameters. To collect the output energy of the TEHNG and continuously send sensing data, a combined power management module (PMM) circuit and energy storage circuit were integrated to efficiently store the obtained electricity. Moreover, a sensing signal processing circuit and a microcontroller unit (MCU) were implemented to process and transmit sensing signals. These four parts were integrated into the TEHNG to realize an all-in-one self-powered microsystem able to drive three sensors (temperature, pressure and ultraviolet) and wirelessly transmit data in real time with total power consumption of about 1.019 mW.

Literature Review

Methodology

Device architecture: The TEHNG employs a spring-cantilever structure to enhance the flexibility of the movable part. The electromagnetic unit consists of a 10,000-turn copper coil (50 mm diameter, 5 mm height) and a neodymium iron boron permanent magnet optimized to 35 mm diameter and 4 mm height. The triboelectric unit uses a PVC film (0.2 mm) and a PDMS film (0.5 mm) as the triboelectric pair with copper as upper/lower electrodes. A PI isolation layer isolates the lower triboelectric electrode from the electromagnetic coil. The overall device integrates on the upper PCB a power management module (PMM), an energy storage circuit (capacitor bank), a sensing signal processing circuit, and a microcontroller unit (MCU) with Bluetooth for data transmission.

Materials optimization: Multiple counter materials paired with PDMS were screened (PTFE, PDMS, SR, PI, paper, PET, PVC, Sn, Al, Cu). Output peak-to-peak voltage and current were measured for each pairing under mechanical excitation. PVC with PDMS delivered the highest output (about 672.0 V and 15.6 µA) attributed to native surface microstructures on PVC, and was selected as the triboelectric counterpart.

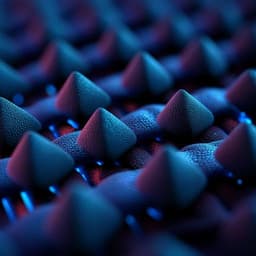

Surface microstructuring: To boost triboelectric performance, PDMS was cast against a silicon template to transfer a pyramid microstructure array (feature width ~13 µm, gap ~4 µm) onto a 0.5 mm-thick PDMS film, increasing effective contact area. Three PDMS variants were fabricated: no microstructures, half-area microstructures, and full-area microstructures; their outputs were compared, showing monotonic improvement with microstructured area, with full-area microstructures chosen.

Working principles: Triboelectric output arises from contact electrification between PVC and PDMS and electrostatic induction between the electrodes during approach-separation motion of the movable and stationary parts. Electromagnetic output is generated in the coil due to changes in magnetic flux as the magnet moves with the movable part, producing alternating currents whose direction depends on approach (clockwise) or separation (anti-clockwise) phases.

Electrical characterization setup: A vibration platform excited the TEHNG at controlled frequencies (0.5–6 Hz). For triboelectric characterization, peak-to-peak voltage (Vpp), current (Ipp), transferred charge per cycle, and load characteristics were measured over external load resistances from 0.1 kΩ to 95.2 MΩ. For electromagnetic characterization, Vpp, Ipp, charge per cycle, and load power versus load resistance were measured. Given typical human motion frequencies (<2 Hz), detailed characterizations were conducted at 2 Hz.

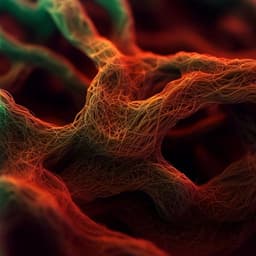

Circuit integration for self-powered operation: The PMM improves energy transfer from the TEHNG to storage capacitors by rectification and impedance matching. Stored energy powers the MCU and three sensors (temperature, pressure, UV). The sensing signal processing circuit conditions sensor outputs, and the MCU samples and transmits data via integrated Bluetooth to external terminals. All circuits are integrated on the TEHNG’s PCB to form an all-in-one self-powered wireless multisensing microsystem (device size approximately 60 mm diameter, 15 mm height).

Key Findings

- Hybridization outcome: The TEHNG achieves a high load power of 21.8 mW by combining a triboelectric unit and an electromagnetic unit with material and configuration optimizations, including pyramid microstructured PDMS.

- Triboelectric unit performance (2 Hz): Average Vpp ≈ 1180.0 V and Ipp ≈ 30.4 µA; transferred charge per cycle ≈ 79.8 nC. Maximum load power to external resistors reached 3.32 mW at a load resistance of 28.5 MΩ. Vpp increased with frequency from 0.5 to 6 Hz, with rapid gains up to ~2 Hz and slower increases thereafter. Full-area pyramid microstructures on PDMS significantly enhanced output compared with no/partial microstructures.

- Electromagnetic unit performance (2 Hz): Average Vpp ≈ 28.0 V and Ipp ≈ 7.4 mA; transferred charge per cycle ≈ 480 µC. Maximum load power was 18.48 mW at a load resistance of 3.90 kΩ, consistent with the coil resistance. Vpp increased with vibration frequency from 0.5 to 6 Hz (6.4 V to 64.0 V).

- Materials selection: Among multiple PDMS-based pairs, PVC+PDMS delivered the best triboelectric output (screening result ~672.0 V and 15.6 µA with smooth PDMS), attributed to native PVC surface microstructures.

- System integration: An all-in-one wireless multisensing microsystem integrating PMM, energy storage, MCU, and sensing signal processing was realized on-board with the TEHNG. The system, with total power consumption ~1.019 mW, continuously operated using only the TEHNG, powering temperature, pressure, and UV sensors and transmitting data via Bluetooth in real time.

- Structural/configurational details: 10,000-turn copper coil (50 mm diameter, 5 mm height); neodymium-iron-boron magnet optimized to 35 mm diameter, 4 mm height; PDMS thickness 0.5 mm with pyramid microstructures (13 µm width, 4 µm gap); PVC thickness 0.2 mm.

Discussion

The study addresses the challenge of insufficient load power from single-mechanism triboelectric harvesters that has limited fully self-powered, continuous, real-time wireless multisensing nodes. By hybridizing triboelectric and electromagnetic mechanisms within a compact spring-cantilever architecture and optimizing both materials (PVC+microstructured PDMS) and electromagnetic configuration (coil turns and magnet dimensions), the TEHNG delivers milliwatt-level output sufficient to continuously power a multi-sensor wireless microsystem. The triboelectric stage benefits from microstructured PDMS that increases effective contact area, raising charge transfer and voltage, while the electromagnetic stage supplies substantial current and load power at lower impedances, complementing the high-impedance triboelectric source. The integrated PMM and energy storage ensure efficient energy transfer and stable power delivery to a low-power MCU and sensors. Operating and characterizing at 2 Hz aligns with human-motion-relevant vibrations, demonstrating feasibility for wearable/IoT contexts. The successful continuous operation of temperature, pressure, and UV sensing with real-time Bluetooth transmission confirms that the hybrid approach overcomes prior power deficits and enables practical, unattended self-powered sensor nodes.

Conclusion

This work presents a compact, high-performance triboelectric–electromagnetic hybrid nanogenerator that, through optimized material pairing (PVC with pyramid-microstructured PDMS) and electromagnetic configuration, achieves up to 21.8 mW output and reliably powers an integrated, all-in-one wireless multisensing microsystem. The system continuously acquires temperature, pressure, and UV data and transmits them in real time via Bluetooth using only harvested mechanical energy, highlighting strong potential to replace or supplement batteries in wearable and industrial IoT nodes. Future research may focus on: enhancing durability and environmental robustness; further miniaturization and flexible form factors; adaptive power management and maximum power point tracking; integration with additional sensing modalities and edge ML; exploration of diverse mechanical energy sources and broadband frequency response; and long-term field testing in real-world scenarios.

Limitations

Related Publications

Explore these studies to deepen your understanding of the subject.