Engineering and Technology

Flexible and efficient perovskite quantum dot solar cells via hybrid interfacial architecture

L. Hu, Q. Zhao, et al.

Discover how the innovative hybrid interfacial architecture using CsPbI3 perovskite quantum dots and PCBM heterojunctions has achieved remarkable solar cell efficiencies. This groundbreaking research showcases the potential for flexible quantum dot photovoltaics, led by esteemed authors including Long Hu, Qian Zhao, and Anita W. Y. Ho-Baillie.

~3 min • Beginner • English

Introduction

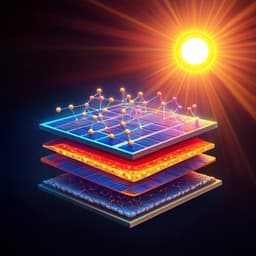

Colloidal quantum dots (QDs) offer tunable optoelectronic properties, strong defect tolerance, and can be processed from nonpolar solvents at room temperature. All-inorganic CsPbI3 perovskite QDs have achieved efficiencies over 15% and provide high open-circuit voltages, but efficient flexible QD photovoltaics have lagged with PCEs typically below 10%, largely due to suboptimal charge transfer and extraction at QD heterointerfaces and at QD/electron-transport-layer (ETL) interfaces. Given QDs’ nanoscale grains and potential for mechanical flexibility and high power-per-weight, the study aims to develop a device strategy that enhances interfacial charge transfer and adhesion to realize high-efficiency, mechanically robust flexible QD solar cells. The research tests a hybrid interfacial architecture (HIA) by incorporating PCBM within CsPbI3 QD layers to form an energy cascade with SnO2 ETLs, hypothesizing improved charge extraction, reduced recombination, and enhanced mechanical endurance.

Literature Review

Prior QD PV studies show PbS QD solar cells reaching 13.8% PCE through surface passivation and device structure optimization. CsPbI3 QD solar cells have surpassed 15% efficiency, benefiting from phase stabilization in QDs and defect tolerance leading to high photoluminescence yields and open-circuit voltages. Unlike thin-film perovskites processed from toxic polar aprotic solvents, QDs are synthesized and processed from nonpolar solvents (hexane, octane, toluene) at room temperature, suiting flexible substrates. Despite demonstrations of flexible QD devices with good bending endurance, reported PCEs have typically been below 10%, attributed to inefficient charge transfer/extraction at interfaces. Flexible organic and thin-film perovskite solar cells have outperformed flexible QD PVs, highlighting a performance gap that this work addresses by engineering QD/ETL interfacial energetics and adhesion via PCBM incorporation.

Methodology

- Materials and QD synthesis: CsPbI3 QDs were synthesized by hot-injection of Cs-oleate into a PbI2 solution in octadecene with oleic acid and oleylamine at 165 °C, quenched after 5 s. Purification involved multiple methyl acetate (MeOAc) anti-solvent precipitations and redispersions to remove excess ligands and precursors. Final QDs were dispersed in octane and chlorobenzene (70 mg/mL). For hybrid blends, PCBM was directly added into CsPbI3 QD chlorobenzene solution at 5 mg/mL:70 mg/mL and stirred in N2 for ≥4 h.

- Film deposition and ligand removal: QD solutions were spin-coated at room temperature (RH <10%). Native long oleate ligands were removed by immersing the as-cast film in anhydrous MeOAc for 20 s. This deposition/ligand-exchange cycle was repeated 3–5 times to form ~300–400 nm films. Hybrid films were prepared by spin-coating PCBM/CsPbI3 blends, followed by identical MeOAc treatment. A control process deposited an ultrathin PCBM layer on SnO2 prior to pure QD layers.

- Device fabrication: Substrates were ITO/glass (rigid) or ITO/PET (flexible). SnO2 (2.5 wt% colloid) was spin-coated and annealed at 120 °C for 30 min; O2 plasma treatment was applied before subsequent layers. Control devices: SnO2/PCBM (ultrathin)/CsPbI3 QD/PTB7/MoO3/Ag. Target devices (HIA): SnO2/PCBM:CsPbI3 hybrid QD layers plus pure CsPbI3 QD layers/PTB7/MoO3/Ag. PTB7 (10 mg/mL in chlorobenzene) was the HTL. Electrodes: 10 nm MoO3 and 100 nm Ag by thermal evaporation. Active area was 0.072 cm2 defined by a mask.

- Thickness optimization: The number of QD deposition cycles was tuned. For HIA, the optimal ratio of hybrid to pure QD layer thickness was 1:4, maximizing PCE.

- Flexible devices: Identical stack on PET/ITO with SnO2 annealed at 120 °C. Mechanical bending tests used a cyclic bending robot at 0.75 cm radius; performance tracked vs cycles.

- Characterization: FTIR for ligand removal and bonding; TEM/SEM/AFM for morphology and roughness; fs-transient absorption (TA) and steady-state/TRPL for carrier dynamics; Space-charge-limited current (SCLC) for trap density; EQE for Jsc integration; J–V under AM1.5G, stabilized power output (SPO) at MPP; EIS (Nyquist) to extract transport and recombination resistances/capacitances; dark J–V; light-intensity dependent Jsc and Voc for recombination analysis; transient photocurrent (TPC) and transient photovoltage (TPV) for carrier transport/recombination lifetimes; UPS and UV-Vis to determine energy levels (VB/CB); contact angle for surface wettability; AFM peak-force to measure Young’s modulus. Comparative films (CsPbI2Br thin film, PbS QD, mixed perovskite thin film) were fabricated per reported recipes for mechanical endurance comparisons.

Key Findings

- Performance: The hybrid interfacial architecture (HIA) with PCBM blended into CsPbI3 QDs yielded a champion PCE of 15.1% with stabilized power output (SPO) of 14.61%, versus 12.4% for control devices lacking the hybrid blend. Improvement was primarily from increased Jsc: EQE-integrated Jsc was 15.1 mA/cm2 (target) vs 12.7 mA/cm2 (control).

- Hysteresis and stability: HIA reduced J–V hysteresis. In storage (dry air box), the control device lost ~50% efficiency vs ~30% for the HIA device after 14 days. Hybrid films showed greater hydrophobicity than control, aiding upper-layer deposition and interfacial contact.

- Carrier dynamics: fs-TA showed faster charge transfer in hybrid films with τ3 (charge transfer) reduced to 312.8 ps from 483.2 ps (control). Auger recombination component τ2 slightly increased (57.6 ps vs 52.3 ps), indicating lower trap density. SCLC confirmed reduced trap density in hybrid films. TRPL showed fastest decay for PCBM/CsPbI3 hybrid films, consistent with enhanced electron extraction.

- Electrical analysis: EIS revealed lower transport resistance (Rtrans) and higher recombination resistance (Rrec) for HIA devices, indicating suppressed interfacial recombination. Dark J–V showed reduced leakage current for HIA. From light-intensity dependence, the Voc slope was 1.29 kT/q (target) vs 1.43 kT/q (control), indicating reduced trap-assisted recombination; bimolecular recombination was present but not dominant and slightly reduced by HIA.

- Transient measurements: TPC indicated shorter carrier lifetime for the HIA device (56 μs) vs control (63 μs), consistent with faster transport. TPV showed longer recombination lifetime for HIA (8.7 μs) vs control (6.5 μs), suggesting reduced recombination.

- Energy alignment: UPS/optical bandgap analysis showed PCBM provides a conduction-band (CB) energy step between CsPbI3 QDs and SnO2, creating an electron cascade that enhances extraction and suppresses interfacial recombination.

- Molecular interactions: XPS peaks (Pb 4f, I 3d, Cs 3d/5) shifted to lower binding energies in hybrid films, evidencing coordination between PCBM carboxyl groups and under-coordinated Pb2+ on QD surfaces. FTIR showed a new peak at ~1663 cm−1 after MeOAc treatment in blends, supporting C=O bonding to QD surface.

- Flexible devices: On PET/ITO, HIA devices reached a record PCE of 12.3% with improved reproducibility. Under 0.75 cm bending radius, QD devices retained ~90% of initial PCE after 100 cycles, versus ~75% for CsPbI2Br thin-film devices.

- Mechanical endurance and mechanics: SEM showed no apparent surface morphology change in CsPbI3 and PbS QD films after up to 1000 bending cycles, whereas CsPbI2Br and mixed perovskite thin films developed cracks, with severe cracking and shedding after extensive cycling. AFM peak-force measurements gave Young’s modulus of ~225 MPa for CsPbI3 QD films vs ~2.3 GPa for perovskite thin films, indicating greater toughness and stress-relief capacity in QD films due to nanoscale boundaries and soft surface ligands.

Discussion

The hybrid interfacial architecture integrating PCBM into the CsPbI3 QD absorber establishes an energy cascade between the QDs and the SnO2 ETL, facilitating rapid electron extraction and suppressing interfacial recombination. Spectroscopic (fs-TA, PL/TRPL) and electrical (EIS, dark J–V, light-intensity Voc/Jsc, TPC/TPV) analyses consistently show improved charge transport, reduced trap density, and diminished recombination losses. Chemical analyses (XPS, FTIR) indicate PCBM’s carboxyl groups coordinate to under-coordinated Pb2+ at QD surfaces, passivating defects and improving interfacial adhesion. The hybrid films’ increased hydrophobicity enhances upper-layer deposition and contributes to improved device stability and reduced hysteresis. Importantly, leveraging the intrinsic nanoscale morphology of QDs leads to superior mechanical endurance relative to bulk perovskite thin films: QD films resist crack formation during bending and exhibit a much lower Young’s modulus, supporting stress dissipation. Consequently, the HIA not only elevates rigid-device efficiency to 15.1% but also enables state-of-the-art flexible QD PVs at 12.3% PCE with robust bending tolerance, addressing a critical performance gap in flexible QD photovoltaics.

Conclusion

A simple hybrid interfacial architecture, formed by blending PCBM into CsPbI3 perovskite QD layers, significantly improves charge transfer and interfacial passivation, yielding champion rigid-device PCE of 15.1% (SPO 14.61%) and record flexible-device PCE of 12.3%. The energy-cascade alignment via PCBM reduces recombination and enhances electron extraction, while the nanoscale grain structure and soft ligand environment confer superior mechanical durability to QD films compared with bulk perovskite thin films. This strategy provides a generalizable pathway to advance high-performance, mechanically robust QD-based optoelectronics. Future work could explore broader interfacial modifiers, scaling deposition methods, longer-term environmental stability, and integration with flexible, robust electrodes to fully exploit QD devices’ potential.

Limitations

- Stability assessments were limited: after 14 days in dry air, HIA devices still showed ~30% efficiency loss, indicating room for further stability improvements.

- Excessive thickness of the hybrid QD layers reduced efficiency (to ~13.8%) due to adverse solvent effects (chlorobenzene) during upper-layer deposition, suggesting processing-window sensitivity.

- Flexible-device degradation under bending may partly stem from rigid ITO/Ag electrodes rather than the QD layer, indicating that electrode fragility influences results.

- Light-intensity Voc slopes (1.29–1.43 kT/q) remain above the ideal value, implying residual trap-assisted recombination; hysteresis was reduced but not eliminated.

Related Publications

Explore these studies to deepen your understanding of the subject.