Chemistry

Efficient overall water splitting in acid with anisotropic metal nanosheets

D. Wu, K. Kusada, et al.

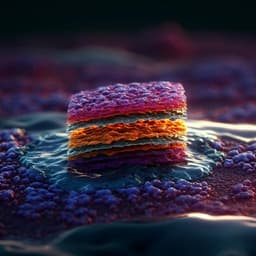

Explore revolutionary advancements in clean hydrogen production with the introduction of the highly efficient Ru-Ir nanocoral (RuIr-NC) catalyst for water splitting in acidic media. This groundbreaking research, conducted by an expert team, unveils a catalyst that not only outperforms existing solutions but also maintains stability for over 120 hours. Join us in discovering the secrets behind its superior performance!

Related Publications

Explore these studies to deepen your understanding of the subject.