Food Science and Technology

Edible mycelium as proliferation and differentiation support for anchorage-dependent animal cells in cultivated meat production

M. Ogawa, A. S. Kermani, et al.

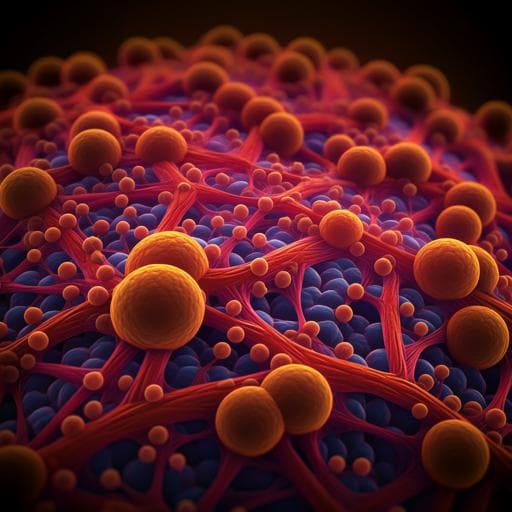

The study addresses the challenge of scaling anchorage-dependent animal cell culture for cultivated meat, which requires significantly higher cell densities and improved productivity per unit of medium. Microcarriers enable suspension culture of adherent cells with high surface-area-to-volume ratios and compatibility with bioreactors. However, conventional microcarriers are typically nonedible synthetic or animal-derived materials, complicating downstream harvesting, increasing cost and waste, and posing potential microplastic risks at large scales. Edible or dissolvable carriers could mitigate these issues by simplifying processes and integrating into the final food product. Prior proof-of-concept work showed that inactivated mycelium from edible filamentous fungi can support myoblast growth, but was limited to a single fungal species and a model cell line. The research question/hypothesis: edible mycelium carriers from various filamentous fungal species can support attachment, proliferation, and differentiation of muscle-relevant cells, including mouse C2C12 myoblasts and bovine satellite cells (bSC), making them suitable for cultivated meat production. The study evaluates the impact of fungal species on cell attachment and metabolism, optimizes seeding densities, and assesses differentiation via myogenic gene expression.

Microcarriers are widely used for bioprocess scale-up of adherent cells due to ease of control, monitoring, cost-effectiveness, and support for bead-to-bead transfer, prolonging exponential growth. Conventional carriers (e.g., polystyrene, cross-linked dextran/cellulose) are optimized for biologics but not for maximizing cell mass and present challenges in trypsinization-based harvesting and sieving, especially at the scales envisioned for cultivated meat (200–250 m3), leading to waste and potential microplastic concerns. Dissolvable carriers (e.g., denatured collagen, alginate, cross-linked polygalacturonic acid) simplify harvesting but add process complexity and require careful control to retain cell function. Edible carriers can be incorporated directly into the final product, enabling texture, flavor, and nutritional contributions while meeting food-grade requirements; however, data on edible carriers that support both proliferation and differentiation are scarce. Filamentous fungi (e.g., Aspergillus oryzae) are GRAS, fast-growing on low-cost substrates, and already used at industrial scale to produce mycoprotein with complete amino acid profiles and favorable digestibility. Previous work demonstrated C2C12 growth on A. oryzae mycelium carriers but was limited in scope (single fungal strain and cell line), highlighting a gap for broader evaluation across fungal species and relevant meat-production cell types.

Study design: Screen multiple filamentous fungal species as edible mycelium carriers for anchorage-dependent muscle cells; compare to nonedible Cytodex microcarriers. Assess cell attachment/proliferation via alamarBlue (AB) metabolic assay and differentiation via myogenic gene expression over time. Cell types: C2C12 mouse myoblasts (including tdTomato-transduced line for imaging) and bovine satellite cells (bSC). Fungal strains: Aspergillus oryzae (two strains; FST 76-2 and UCD 8), Aspergillus awamori FST 40-400, Aspergillus sojae FST 76-1, Aspergillus nishimurae UCD 15, Aspergillus tubingensis UCD 12, Rhizopus oligosporus FST 72-2, and Penicillium chrysogenum H3. Culture and carrier preparation: Filamentous fungi were pre-grown on sporulation agar (corn meal agar, yeast extract, glucose, bactoagar). Pellets were produced in a defined pellet medium (6% glucose, 0.3% yeast extract, 0.3% NaNO3, 0.1% K2HPO4, 0.05% MgSO4, 0.05% KCl, 0.001% FeSO4). Pellets were inactivated; inactivation was checked on YPD plates. Carriers were normalized by available surface area per well for comparisons. Animal cell culture: C2C12 were maintained in proliferation medium (DMEM + 10% FBS + 1% Pen/Strep) and differentiated in DMEM + 2% horse serum + 1% Pen/Strep. C2C12 were lentivirally transduced with tdTomato (MOI ~7.5) and clonal lines selected for imaging. bSC were cultured at 37 °C, 5% CO2. Seeding density studies: For C2C12 on Cytodex and mycelium (A. oryzae FST 76-2), seeding densities were 5×10^2, 5×10^3, 5×10^4, 5×10^5, 5×10^6 cells/mL (and one additional high-density condition at 10^7 cells/well reported). For bSC, seeding densities ranged from 1×10^3 to 2.5×10^6 cells/mL in various experiments; key comparisons highlighted 5×10^5 and 1×10^6 cells/mL. Proliferation and metabolic activity: AB assay performed 48 h after seeding; read at 570/600 nm; percent reduction calculated per manufacturer instructions. Measurements taken at 24 h and 72 h to infer proliferation over 48 h. Differentiation assays: Carriers with >90% confluent C2C12 were switched to differentiation media; samples collected at T1 (48 h), T2 (96 h), T3 (168 h) after switch; Cytodex used as a benchmark. bSC differentiation evaluated at the same time points post-switch. RNA extraction with TRIzol, cDNA synthesis (Qiagen), and TaqMan qPCR for myogenic markers. C2C12 markers: GAPDH control; PAX7, MYOD1, MYOG, MYH2. bSC markers: GAPDH control; MYOD1, MYOG, MYH1/2, MYH3; PAX7 assay (rabbit) attempted but undetected. Imaging: Fluorescence microscopy (ImagePICO) with z-stacks; C2C12-tdTomato imaged in TRITC channel (10×); bSC stained with Hoechst 33342 and imaged in DAPI (20×). Statistics: ANOVA and Fisher’s LSD for homogeneous groups; two-tailed unpaired t-tests; significance at p≤0.05 unless noted; n≥3 biological replicates per condition/time point.

- Fungal species screen for C2C12 attachment/metabolic activity (48 h AB reduction): A. oryzae 1 (FST 76-2): 29.00 ± 0.03%; A. oryzae 2 (UCD 8): 24.06 ± 0.11%; A. awamori: 23.80 ± 0.07%; A. sojae: 9.4 ± 0.02% (weak); R. oligosporus: 3.00 ± 0.01%; A. nishimurae: 5.38 ± 0.02%; P. chrysogenum: 5.19 ± 0.01%; A. tubingensis: 4.29 ± 0.01%. Non-supportive species were not significantly different from no-microcarrier controls, suggesting poor attachment. A. oryzae 1 selected for follow-up. - C2C12 seeding density effects: On Cytodex at 5×10^6 cells/mL, AB reduction increased 7.6 ± 0.2% → 21.3 ± 1.8% (24 h → 72 h). On mycelium carriers, high seeding densities gave the largest gains: 5×10^5: 8.3 ± 1.0% → 33.7 ± 5.5%; 5×10^6: 9.4 ± 2.2% → 33.2 ± 1.9%. At 10^7 cells/well: 6.6 ± 0.7% → 17.0 ± 0.8%. Low-density seeding (≤5×10^3 cells/mL) did not show proliferation on mycelium or Cytodex. Imaging showed C2C12 coverage of mycelium with small cell aggregates around pellet surfaces; no microcarrier controls formed large aggregates with low activity. - C2C12 differentiation on carriers: On Cytodex, PAX7 decreased from T1→T2; MYOD1 decreased T2→T3; MYOG increased T1→T2 then slightly decreased; MYH2 strongly expressed across time. On mycelium, PAX7 detected without significant change; MYOD1 increased T1→T2 and plateaued; MYOG increased steadily at each time point; MYH2 strongly expressed at all times. These patterns indicate successful myogenic differentiation on mycelium carriers. - bSC attachment and proliferation: Imaging confirmed attachment on Cytodex and mycelium. On Cytodex, at 1×10^6 cells/mL, AB increased 7.0 ± 0.2% → 16.7 ± 0.6%. On mycelium, proliferation occurred across seeding densities; at 1×10^6 cells/mL, AB increased 4.0 ± 0.5% → 18.4 ± 1.4%, surpassing Cytodex at 72 h. Mycelium exceeded Cytodex at 5×10^5 and 1×10^6 cells/mL at T3. - bSC differentiation markers: MYOD1 decreased over time on both carrier types; MYOG decreased from T1→T3 on Cytodex and was weak/undetected by T3 on mycelium; MYH1/2 sporadically detected; MYH3 clearly detected on both carriers with a significant reduction T1→T2 on Cytodex only. Overall, data indicate bSC can differentiate on mycelium carriers.

The findings support the hypothesis that edible mycelium carriers can sustain attachment, proliferation, and myogenic differentiation of relevant muscle cells. Species-specific differences in C2C12 metabolic activity suggest that carrier surface properties (e.g., pellet size, compactness, hydrophobicity, stiffness, topography, residual metabolites) critically influence attachment and growth. A. oryzae-based carriers performed best under the tested conditions. High seeding densities (5×10^5–5×10^6 cells/mL) improved proliferation on mycelium, while comparable conditions in Cytodex or suspension led to large, less viable aggregates. Mycelium carriers promoted the formation of numerous small aggregates localized around pellet surfaces, potentially minimizing diffusion limitations and necrosis in contrast to larger aggregates. C2C12 exhibited robust differentiation on mycelium (increasing MYOD1 and MYOG; strong MYH2), while persistent PAX7 expression suggests concurrent proliferative subpopulations due to heterogeneous microenvironments within the porous mycelial matrix. bSC attached and proliferated on mycelium carriers, in some cases exceeding Cytodex at similar seeding densities, and expressed late myogenic markers (e.g., MYH3), indicating differentiation capacity. Collectively, these results highlight the suitability of edible mycelium carriers for integrated proliferation and differentiation workflows, providing a path toward simplified, single-bioreactor processes in cultivated meat that integrate the carrier into the final product and contribute to texture, flavor, and nutrition.

This study expands prior proof-of-concept work by demonstrating that edible mycelium carriers, particularly those derived from Aspergillus oryzae, can support attachment, proliferation, and differentiation of both C2C12 myoblasts and bovine satellite cells. Mycelium carriers outperformed or matched nonedible Cytodex in several proliferation conditions and enabled expression of key myogenic differentiation markers. The technology offers advantages for cultivated meat, including process simplification (no carrier removal), potential for a one-step proliferation/differentiation process in a single bioreactor, and contributions to final product properties (texture, flavor, nutrition). Future research should: characterize carrier surface properties (e.g., specific surface area, topography, mechanics) across fungal strains; perform high-throughput screening to match strains to cell types; optimize culture parameters (DO, pH, feeding) for higher productivity; validate scale-up with agitation, bead-to-bead transfer, and bioreactor operation; and assess sensory/nutritional impacts of strains. Genetic engineering of filamentous fungi may further tailor carriers for enhanced cell performance or improved sensory attributes.

- Experiments were conducted in static microwell plates; no stirred bioreactor validation or bead-to-bead transfer experiments were performed. - Quantitative characterization of fungal pellet specific surface area and topology was not achieved, limiting normalization of available attachment area beyond approximate surface area estimates. - Gene expression analyses had incomplete amplification for some targets/samples, complicating trend assessments (e.g., MYOG, MYH1/2 in bSC). - bSC PAX7 was probed using a rabbit assay due to lack of bovine-specific assay and showed no detectable expression, limiting interpretation of stemness maintenance. - Detailed follow-up studies focused primarily on A. oryzae 1; broader optimization across additional strains and process parameters remains to be done.

Related Publications

Explore these studies to deepen your understanding of the subject.