Food Science and Technology

Cultured meat with enriched organoleptic properties by regulating cell differentiation

M. Lee, S. Park, et al.

Discover how a team of researchers, including Milae Lee and Sohyeon Park, is revolutionizing cultured meat by enhancing its organoleptic and nutritional qualities through innovative scaffold engineering. Their breakthrough allows the creation of meat with taste profiles that closely mimic traditional beef, opening new avenues for sustainable food production.

~3 min • Beginner • English

Introduction

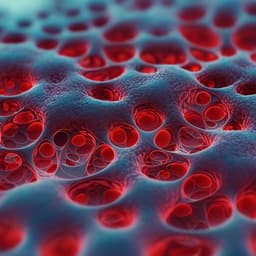

The study addresses the gap in cultured meat research concerning food-related qualities—sensorial properties and nutritional value—beyond cell proliferation and differentiation. Since organoleptic properties of conventional meat are governed by biological characteristics of muscle and fat tissues (e.g., myofiber dimensions, lipid content), the hypothesis is that controlling cellular differentiation of muscle and adipose cells via scaffold mechanics can tune these food properties. Mechanical cues, particularly scaffold stiffness, are known to regulate lineage commitment; approximately 10–12 kPa supports myogenesis and ~3 kPa supports adipogenesis. Gelatin offers biocompatibility and food relevance but requires crosslinking for stability; microbial transglutaminase (mTG) provides non-toxic crosslinking. Alginate, crosslinked with calcium, enables stiffness tuning through crosslink density. The purpose is to engineer gelatin/alginate 2D hydrogels with controlled stiffness to direct primary bovine myoblast and adMSC differentiation, then assemble optimized muscle and fat blocks to produce cultured meat with beef-like texture and flavor profiles.

Literature Review

Prior cultured meat scaffold approaches include 3D bioprinted bioinks, textured soy protein, and decellularized plant tissues (e.g., spinach) focusing on structure and cell differentiation occurrence rather than food characteristics. Mechanical regulation of stem cell fate via matrix elasticity is established, and alginate stiffness can be tuned via calcium crosslinking. Gelatin is widely used for cell adhesion and as a food additive; traditional crosslinkers can be cytotoxic, whereas mTG is food-safe and effective for gelatin crosslinking. Meat quality determinants include muscle fiber properties and lipid composition, impacting flavor and texture through protein denaturation (e.g., MHC, actin) and lipid oxidation products. This study builds on these insights to connect scaffold mechanics-driven differentiation to organoleptic outcomes.

Methodology

Scaffold fabrication: Hydrogels comprised fish gelatin and alginate. Two alginate concentrations: LA (0.25% w/v) and HA (2% w/v), both with 10% (w/v) gelatin and 1% (w/v) mTG. Gelatin was enzymatically crosslinked by mTG (gel at 4 °C, activate at 37 °C overnight). Alginate networks were ionically crosslinked in CaCl2 for two crosslinking degrees: LC (alginate:Ca 1:0.5; CaCl2 0.125% for LALC, 1% for HALC) and HC (1:1; CaCl2 0.25% for LAHC, 2% for HAHC). Groups: LALC, LAHC, HALC, HAHC.

Scaffold characterization: Raman spectroscopy assessed alginate Na+ to Ca2+ crosslinking (shift ~1400 to ~1420 cm−1; Ca-alginate fraction quantified). Compressive testing (Instron) measured Young’s modulus (0–50% compressive strain). Degradation assessed by 12-day incubation in myoblast-conditioned medium at 37 °C.

Cells: Primary bovine myoblasts isolated from gluteobiceps/semitendinosus; adMSCs from intramuscular/subcutaneous adipose tissue of 29–31-month-old Hanwoo cattle, following enzymatic digestion, selection, and culture protocols. Ethics approved by Kangwon National University IACUC (KW-220714-1).

Cell culture: Myoblasts (P3) seeded 3×10^4 per 12-well scaffold; proliferated 4 days then switched to differentiation medium (HG-DMEM + 5% horse serum + antibiotics). adMSCs (P3) seeded 2×10^4 per scaffold; proliferated 3 days then adipogenic medium (LG-DMEM + 5% FBS, 10 μM insulin, 1 μM dexamethasone, 10 μM ciglitazone, 100 μM oleic acid). Viability by CCK-8.

Differentiation assays: Myogenesis via MHC immunostaining (MF20) and ELISA for MYH1; proteomics by LC-MS/MS with TMTpro labeling and DAVID annotation. Adipogenesis via Oil Red O quantification and LipidTOX staining (coverage, droplet number per cell); proteomics with focus on lipid metabolism markers (e.g., ADIPOQ). Undifferentiated controls assessed.

Rheology: Frequency-sweep rheometry (37 °C) converted to Young’s modulus (E = 2G(1+ν), ν=0.5). Heating tests at 60 °C assessed stiffness changes (protein denaturation vs collagen).

Flavor analysis: GC-MS with HS-SPME (CAR/PDMS/DVB fiber; oven 40 °C 5 min to 240 °C at 4 °C/min, hold 20 min) on grilled samples (180 °C; 5–10 min depending on experiment). Volatile identification via FEMA/TGSC libraries. Target compounds included Maillard-derived benzaldehyde, 2,5-dimethylpyrazine; lipid-oxidation volatiles nonanal and 2-ethyl-1-hexanol.

Assembly: Muscle (HALC + myoblasts) and fat blocks (LALC + adMSCs) bonded using mTG solution (30% w/v), wrapped and incubated 1 h at 37 °C to form ACM. Configured muscle:fat at 3:1 to mimic beef brisket; larger assemblies produced an engineered T-bone steak (strip loin and tenderloin) using puzzle-like interlocking blocks with specified ratios.

Food analyses: Nutrition (protein via Kjeldahl-type titration; fat via FID; carbohydrate by difference) on 100-mm dish-scale ACM; texture profile analysis (TPA) of grilled samples (180 °C, 10 min) measuring cohesiveness, springiness, hardness; chewiness computed. Statistics: mean±SD, n=3 independent experiments, two-tailed Student’s t-test.

Key Findings

- Scaffold mechanics: Raman confirmed higher Ca-alginate content with increased Ca2+ (e.g., LAHC vs LALC; HAHC vs HALC). Compression testing showed stiffness increased with alginate concentration and crosslinking. LALC and HALC matched tissue-like moduli: ~3 kPa (adipose) and ~11 kPa (muscle), respectively, and were used for adipogenesis and myogenesis.

- Myogenesis (HALC > LALC): Confocal MHC staining showed nuclei fusion by day 5 and branched myotubes by day 8 in HALC; minimal staining in LALC. Proteomics: HALC upregulated muscle/cytoskeleton/actin-binding proteins (>1.5-fold). MHC ELISA and total protein were significantly higher in HALC than LALC after differentiation; no significant differences in undifferentiated controls, indicating stiffness-driven differentiation.

- Texture upon heating: HALC stiffness significantly increased after heating to 60 °C due to abundant myofibrillar protein denaturation/aggregation (MHC), overriding collagen denaturation effects; bare scaffolds showed no such increase, and undifferentiated groups showed decreased stiffness upon heating.

- Myogenesis-driven flavors: GC-MS on grilled samples (180 °C, 5 min) detected Maillard products. Benzaldehyde peak area was ~2.2× higher vs bare HALC and ~3× vs LALC; 2,5-dimethylpyrazine (roasted beef-like) was detected only in HALC with differentiated cells. Undifferentiated groups lacked pyrazine and showed no benzaldehyde differences between LALC and HALC.

- Adipogenesis (LALC > HALC): Oil Red O quantification showed significantly higher lipid droplets in LALC (p=0.036). LipidTOX analysis: higher droplet coverage (p=0.0221) and number per cell (p=1.9×10^-5) in LALC. Proteomics in LALC upregulated lipid/fatty acid metabolism and adipogenesis markers (e.g., ADIPOQ). Undifferentiated groups had fewer differences.

- Adipogenesis-driven flavors: In LALC with differentiated adMSCs, the summed normalized peak area of nonanal and 2-ethyl-1-hexanol (fatty notes) significantly increased vs bare LALC (p=0.012); no change in HALC or undifferentiated controls.

- Assembled cultured meat (ACM): Muscle:fat 3:1 assembly produced an ACM with all macronutrients. Nutrition per 100 g: Beef—protein 19.88 g, fat 6.7 g (sat 3.29 g; unsat 3.41 g), carbohydrate 7.97 g; ACM—protein 10.71 g, fat 0.137 g (sat 0.12 g; unsat 0.017 g), carbohydrate 3 g. Differentiated ACM had higher protein than bare/undifferentiated ACM.

- Flavor comparison (grilled 180 °C, 10 min): ACM and beef shared flavor notes (almond, fat, fried-like). Some flavor categories showed significant differences (e.g., deep-fried p=0.006; fat/oil p=0.011), while bitter almond and fat/green were not significantly different. Differentiated ACM showed higher peak ratios than bare/undifferentiated ACM due to increased proteins and lipids.

- Texture profile analysis: ACM exhibited higher springiness and tenderness (lower hardness) than beef, with similar cohesiveness; chewiness derived from measured parameters differed significantly (reported p-values indicated significance). Differentiated ACM had higher cohesiveness than bare/undifferentiated ACM, attributable to muscle proteins.

- Scale-up demonstration: An engineered T-bone steak was assembled from interlocked 2D blocks to mimic strip loin and tenderloin ratios; grilling produced browning consistent with Maillard reactions, showcasing structural and sensorial mimicry potential.

Discussion

The findings demonstrate that tuning scaffold stiffness to align with native tissue mechanics effectively directs myogenesis (~11 kPa) and adipogenesis (~3 kPa), and that the resulting differentiation state directly modulates organoleptic properties of cultured meat. Enhanced myogenesis increased cellular protein content, which upon heating led to greater protein denaturation/aggregation, increasing cooked stiffness and contributing to meat-like texture. Elevated protein content also promoted Maillard reactions, enriching savory, roasted flavors (e.g., benzaldehyde, pyrazines). Conversely, enhanced adipogenesis elevated intracellular lipid droplets, which upon oxidation yielded fatty flavor volatiles (nonanal, 2-ethyl-1-hexanol), contributing to characteristic fat-associated notes and potentially to mouthfeel and taste via fatty acid signaling. Assembling optimized muscle and fat blocks yielded an ACM with flavor profiles similar to beef and measurable improvements in textural attributes relative to controls, although with differences compared to conventional beef. Overall, the study links scaffold-mechanics-driven differentiation to concrete sensory and nutritional outcomes, providing a pathway to tailor cultured meat quality by engineering the cellular microenvironment.

Conclusion

This work introduces a scaffold engineering strategy to enrich the sensory and nutritional properties of cultured meat by regulating the differentiation of primary bovine myoblasts and adMSCs on gelatin/alginate hydrogels with tuned stiffness. Optimized conditions (HALC for myogenesis; LALC for adipogenesis) produced muscle and fat blocks that, when assembled, yielded an ACM exhibiting beef-like flavor notes, improved protein content over undifferentiated constructs, and distinct textural attributes upon cooking. The approach was further validated by constructing an engineered T-bone steak from interlocked blocks to mimic different cuts. Future research should focus on achieving fully matured adipocytes and myofibers, expanding to plant-derived or edible-grade scaffolds while maintaining cytoaffinity, integrating vascularization or perfusion for thicker constructs, comprehensive sensory panel evaluations, and further optimization of nutrient composition and flavor complexity to more closely match various beef cuts.

Limitations

- Adipocyte maturity was not fully evaluated; adipogenesis effects on stiffness were not significant at this early stage and require confirmation with mature adipocytes.

- Protein content of ACM remained lower than beef; some characteristic beef flavor compounds were not detected in ACM.

- The study utilized 2D hydrogel blocks; mass transport and viability considerations in larger 3D constructs were not addressed.

- Scaffolds were animal-derived (gelatin); translation to fully plant-derived edible scaffolds was not validated.

- Sensory evaluation by human panels was not reported; flavor analysis was instrumental only.

- Sample sizes were n=3 for most assays; broader validation is needed.

Related Publications

Explore these studies to deepen your understanding of the subject.