Chemistry

A sustainable synthesis of the SARS-CoV-2 Mpro inhibitor nirmatrelvir, the active ingredient in Paxlovid

J. R. A. Kincaid, J. C. Caravez, et al.

The COVID-19 pandemic created urgent demand for both prophylactic and therapeutic options. Nirmatrelvir (PF-07321332), the SARS-CoV-2 main protease inhibitor in the oral combination drug Paxlovid, was authorized based on its ability to significantly reduce progression to severe disease. Meeting global demand requires routes that are cost-effective, scalable, and environmentally responsible. Existing syntheses, including Pfizer’s initial and updated routes, still leave opportunities to reduce environmental footprint, simplify operations, avoid epimerization, and eliminate hazardous reagents (e.g., Burgess reagent, traditional peptide coupling agents). The aim of this study is to develop a concise, convergent, green synthesis of nirmatrelvir featuring pot and time economy, minimal waste, avoidance of epimerization, and improved overall yield while enabling manufacturing at scale.

Early COVID-19 treatment efforts focused on repurposed drugs with limited success. Multiple novel antivirals have been pursued (e.g., molnupiravir by Merck, EDP-235 by Enanta, S-217622 by Shionogi). Pfizer’s Paxlovid (nirmatrelvir plus ritonavir) achieved emergency authorization with strong clinical impact. However, the original and modified Pfizer routes involve peptide coupling reagents and, in places, less sustainable solvents/reagents (e.g., Burgess reagent for amide dehydration). Patents describe alternative convergent approaches, but complete experimental details for Pfizer’s second-generation route were not fully available, complicating direct comparison. An alternative patented route with complete detail gave an overall yield of 7.6% due to low-yielding steps. This context underscores the need for greener, higher-yielding, and operationally simpler routes.

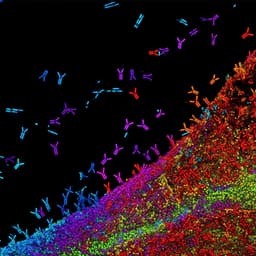

Overall strategy: A 7-step, 3-pot, convergent synthesis emphasizing green chemistry, pot economy, and avoidance of epimerization. Key features include in-pot thioester formation and amide coupling in EtOAc using di-2-pyridylthiocarbonate (DPTDC), simplified aqueous workups, and a palladium-catalyzed amide-to-nitrile dehydration that avoids Burgess reagent and chlorinated solvents. DFT was used to analyze tertiary amide rotamers in nirmatrelvir.

- Thioester/amide coupling technology: Carboxylic acids are converted to thioesters using DPTDC in EtOAc with catalytic DMAP at room temperature. The 2-mercaptopyridine by-product is removed via in-flask aqueous base washes and is recoverable/recyclable. Thioesters (e.g., intermediates 3 and 7) are stable and serve as efficient activated species for amide bond formation, avoiding traditional peptide coupling reagents and minimizing epimerization.

- First 1-pot, 3-step sequence to intermediate 6: N-Boc L-leucine (2) is converted to thioester 3 (DPTDC, EtOAc, catalytic DMAP, rt). After simple aqueous base workup and concentration, coupling with bicyclic proline derivative 4 in EtOAc with N-methylmorpholine (NMM) and gentle heating affords amide 5. The methyl ester present is hydrolyzed with LiOH in aqueous THF; neutralization and minimal EtOAc extraction provide acid 6 without chromatographic purification (78% over 3 steps). Small impurities (e.g., 2,2′-dipyridyldisulfide) are benign; stoichiometry is adjusted based on qNMR of crude 6.

- Second 1-pot, 2-step sequence to tripeptide 9: Acid 6 is converted in situ to thioester 7 (DPTDC conditions). Without isolation, coupling with aminonitrile 8 in an ethereal/EtOAc medium at low temperature (0 °C) provides tripeptide 9 in 94% yield over the two steps. This convergent amide formation avoids the higher-step-count approaches and sidesteps use of the Burgess reagent in earlier literature routes.

- Final 1-pot, 2-step sequence to nirmatrelvir (1): N-Boc deprotection of 9 is effected using HCl (e.g., HCl in dioxane/CH2Cl2) rather than TFA to avoid epimerization. The resulting amine hydrochloride (observed as a rotameric mixture, 10a/10b) is equilibrated at room temperature overnight to enrich the major rotamer (ca. 94:6 to 96:4). Solvent and excess HCl are removed, and trifluoroacetylation with trifluoroacetic anhydride (TFAA) and NMM installs the trifluoroacetamide, furnishing nirmatrelvir (95% yield over the two steps; 95% HPLC purity prior to MTBE solvate formation/recrystallization).

- Green amide dehydration to aminonitrile 8: The key nitrile-bearing amine 8 is made from the corresponding primary amide via a palladium-catalyzed “amide exchange” dehydration using a sacrificial fluorocarboxamide donor in a greener medium, avoiding Burgess reagent and chlorinated solvents. The nitrile is obtained in high yield (e.g., ca. 93%), with impurity removal by crystallization of a downstream intermediate when needed. To limit hydrolysis during Boc deprotection of nitriles, materials are dried azeotropically to remove adventitious water.

- Computational analysis: DFT (B3LYP-D3BJ/6-31G(d,p), SMD in MeCN) was used to model nirmatrelvir conformers. The major rotamer features a cis-like, 7-membered intramolecular H-bond involving the tertiary amide; the computed barrier for rotamer interconversion is high relative to acetamide.

- Workup and solvent considerations: Reactions are designed for in-pot aqueous washes, recovery/minimization of organic solvents (favoring EtOAc), and avoidance of hazardous or non-recyclable media wherever possible. Subsequent steps after the Pd-catalyzed dehydration provide opportunities to reduce residual palladium in the final API.

- Route performance: 7-step, 3-pot synthesis delivering nirmatrelvir in 70% overall yield, exceeding Pfizer’s reported 48% for their published route. Subsequence yields include 78% (first 3 steps to 6), 94% (next 2 steps to 9), and 95% (final 2 steps to nirmatrelvir) with 95% HPLC purity prior to MTBE solvate recrystallization.

- Greener chemistry: Amide couplings proceed via in situ thioesters (DPTDC) in EtOAc, avoiding traditional peptide coupling reagents and associated waste/epimerization. Primary amide dehydration to nitrile avoids Burgess reagent and chlorinated solvents by using a Pd-catalyzed “amide exchange.” By-products (e.g., 2-mercaptopyridine) are readily removed and recyclable.

- Environmental metrics: Reported E Factor (all waste) reduced from 214 (Pfizer) to 120 (this work). E Factor excluding aqueous waste reduced from 108 to 54. Solvent usage emphasizes recyclable EtOAc in place of DMF/MEK where possible.

- Convergency and pot economy: Two 1-pot sequences (3-step and 2-step) to key intermediates and a final 1-pot, 2-step deprotection/acylation streamline operations and reduce workups.

- Stereochemical integrity: Conditions minimize epimerization; TFA for Boc removal led to measurable epimerization (~8% upon exposure), whereas HCl or base avoided epimerization. Rotamer equilibration prior to trifluoroacetylation further improved outcomes.

- Rotamer/DFT insights: NMR shows predominantly one rotamer in DMSO with ~5% minor rotamer. DFT predicts the major rotamer stabilized by a 7-membered intramolecular H-bond. The computed rotational barrier between rotamers is about 25.25 kcal/mol at 298 K (MeCN, SMD), higher than the 17.7 kcal/mol experimental barrier for acetamide, consistent with unusually slow rotamer equilibration at room temperature.

The study addresses the need for a scalable, cost-effective, and environmentally responsible synthesis of nirmatrelvir by implementing a convergent route with pot economy and green transformations. Avoiding traditional peptide coupling reagents and the Burgess reagent reduces hazardous waste and cost while improving operational simplicity. Stable thioester intermediates enable high-yielding amide formations with minimal epimerization. The Pd-catalyzed amide-to-nitrile dehydration provides a greener alternative to established methods. Collectively, these features increase overall yield to 70% and halve the E Factor excluding aqueous waste compared to Pfizer’s published route, indicating significant sustainability gains. The DFT-backed understanding of tertiary amide rotamers explains NMR observations and supports the choice of deprotection and acylation conditions that minimize epimerization and side-product formation, thereby stabilizing product quality and facilitating scale-up. These advances are directly relevant to expanding global access to Paxlovid by lowering environmental footprint and anticipated manufacturing costs.

This work presents a concise, convergent, and greener 7-step, 3-pot synthesis of nirmatrelvir in 70% overall yield. Key advances include: (i) 1-pot thioester-mediated amide bond formations in EtOAc that avoid traditional coupling reagents; (ii) a Pd-catalyzed amide dehydration that replaces Burgess reagent and chlorinated solvents; (iii) conditions that maintain stereochemical integrity and mitigate rotamer-related complications; and (iv) substantially improved environmental metrics (E Factor and solvent profile) relative to prior routes. These features make the route attractive for large-scale manufacturing aimed at broad, global deployment. Future work could further refine the dehydration step to replace sacrificial donors with more benign alternatives, optimize solvent recovery at scale, and deepen understanding of rotamer dynamics to guide downstream processing.

- Comparison constraints: Direct, comprehensive comparison with Pfizer’s second-generation route was not possible due to incomplete published experimental details; comparisons were made to their published/best available data.

- Dehydration donor: The sacrificial fluorocarboxamide used in the Pd-catalyzed dehydration may raise cost/toxicity concerns; while impurities can be removed by crystallization, more benign donors are desirable for large-scale implementation.

- Deprotection sensitivity: Boc deprotection using TFA induced epimerization; HCl-based methods required careful control and rotamer equilibration. Adventitious water during Boc deprotection of nitriles led to hydrolysis by-products, necessitating rigorous drying/azeotropic procedures.

- Residual metal: Although downstream steps help limit residual Pd, metal management remains an operational consideration in scale-up.

- Some steps used limited amounts of chlorinated solvents during deprotection; broader elimination or substitution may be needed in certain manufacturing contexts.

Related Publications

Explore these studies to deepen your understanding of the subject.