Engineering and Technology

A new route to fabricate flexible, breathable composites with advanced thermal management capability for wearable electronics

H. Chen, Y. Ding, et al.

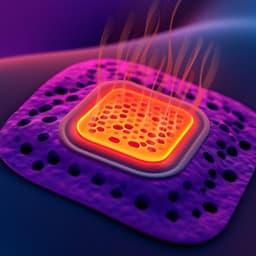

The study addresses the central challenge in wearable electronics of simultaneously achieving high thermal management capability, mechanical flexibility/stretchability, and breathability. Miniaturization and high power densities in flexible systems cause heat accumulation, demanding efficient heat dissipation while preserving comfort and skin safety via air and vapor permeability. Conventional polymers are flexible and processable but possess intrinsically low thermal conductivity (< ~0.5 W m⁻¹ K⁻¹). Adding highly thermally conductive fillers improves heat transport but can compromise permeability and flexibility. The authors propose a composite architecture based on patterned electrospun TPU fibrous mats whose grid regions are selectively coated with an Ecoflex-boron nitride nanosheet (BNNS) layer to form thermally conductive pathways while retaining porous, breathable regions. The work aims to demonstrate that this design can deliver substantial thermal conductivity enhancement with minimal loss of breathability and excellent flexibility, and to validate thermal management improvements in integrated flexible devices.

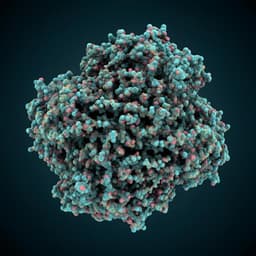

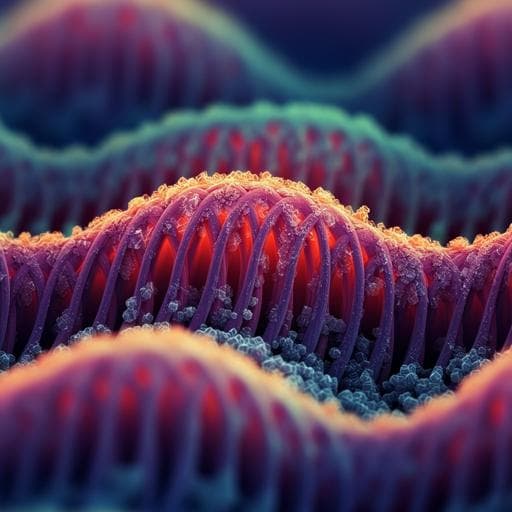

Electrospinning produces porous nano/microfibrous membranes with large surface area and tunable morphology, making them suitable substrates for breathable flexible devices. TPU is a desirable electrospinnable polymer for wearables due to biocompatibility, hydrophobicity, and toughness. However, porous fibrous mats typically act as thermal insulators because of low k. For modern electronics with high integration and heat flux, enhancing thermal dissipation is critical. High-k crystalline fillers (metals, graphene/CNTs, ceramics) are effective but often rigid or electrically conductive. BNNSs provide ultrahigh intrinsic thermal conductivity (~1700–2000 W m⁻¹ K⁻¹) and electrical insulation, making them attractive for thermally conductive yet electrically insulating composites. The authors also note a theoretical link between thermal conductivity and elasticity (k ≈ C√E/(3√P)), implying a trade-off: increasing modulus can improve k but reduces flexibility. Prior works show electrospinning can increase thermal conductivity in certain polymers via chain alignment in ultrathin fibers, but achieving that often raises modulus, undesirable for wearables. Thus, selectively constructing conductive pathways using BNNSs while preserving porous architecture is posited as a means to reconcile these competing demands.

- BNNS exfoliation: Liquid-phase exfoliation from h-BN. 3.5 g h-BN in 200 mL isopropanol:DI water (1:1 by weight), bath sonication 4 h at 20 kHz. Centrifuge 4000 rpm for 10 min to remove unexfoliated h-BN; collect supernatant and centrifuge 9000 rpm for 30 min to obtain BNNSs.

- Electrospun patterned TPU fibrous membrane: Solvent DMF:THF = 1:1 (w/w). TPU concentration 15 wt% with stirring 3 h to form uniform precursor. Electrospinning on steel wire mesh (metal grid) collector to create patterned fibrous architecture. Applied voltage ~15 kV; spinneret-collector distance ~16 cm; electrospinning time 8 h; room temperature, 20–50% RH.

- Composite fabrication (thermally conductive layer deposition): Prepare Ecoflex-BNNSs by mixing Ecoflex A:B = 1:1 (w/w). Add BNNSs to Part A and stir 30 min; add Part B and continue stirring until uniform. BNNS loadings: 10, 20, 25 wt%. Coat Ecoflex-BNNSs selectively along patterned fibrous grids using a metal mask. Composite layer thickness ~0.3 mm. Note: >25 wt% BNNSs resulted in viscous, poorly flowable mixtures.

- Device fabrication: For breathable flexible conductor/strain sensor, spray-coat graphene onto patterned TPU grids via mask to define conductive pathways; then coat Ecoflex-BNNSs through the mask to encapsulate/insulate graphene. Vacuum dry 6 h; attach Cu foils as electrodes on exposed ends.

- Prototype with inkjet-printed Ag conductors: Print serpentine Ag conductors (resistance ~2 Ω) on Ecoflex-BNNSs film (25 wt% BNNSs, ~0.3 mm) using pneumatic extrusion flexible electronics printer (MP1100, Prtronic) with commercial Ag ink (BASE-CD01). UV/O3 surface treatment prior to printing. Vacuum dry at 120 °C for 30 min. Subsequent electrospinning deposits fibers preferentially onto the conductive Ag patterns; structures can be cut along edges as needed.

- Characterization and testing: • Morphology: SEM (Nova Nano SEM 450). Optical images via smartphone. • Mechanical: Strain-stress via DMA (Q-800). Stretching/bending durability up to >2000 cycles; strain ~100% where noted. • Breathability: Air permeability via YG461E-11. Water vapor permeability by weight loss of DI water in bottles covered with samples vs controls (plastic wrap, pure patterned TPU, uncovered) at room temperature, 30% RH. • Thermal transport of single TPU fiber: Thermal bridge method using suspended SiNx microdevice with Pt resistance thermometers as heater/sensor, in high vacuum (~1×10⁻⁶ mbar). Joule heating on heater membrane; measure temperature rise via resistance. Extract total thermal resistance (R_G), separate intrinsic (R_i) and thermal contact resistance (R_tc) by measuring multiple lengths (L) with similar diameters (d), plotting R_i·d vs L/d to extrapolate R_tc at L=0. Compute k from k = L·d / R_i. Validate with COMSOL Multiphysics finite element simulation of device geometry and materials. • Bulk/composite thermal conductivity: Hot Disk TPS 2500S. Bending/stretching cycling effects assessed up to 800 cycles (strain ~100%). • Device thermal performance: Apply fixed voltages (e.g., 10 V for graphene-based devices; 2.5 V for Ag prototype) and monitor surface temperature dynamics and equilibrium using IR thermography (FOTRIC-226-2). Bending-releasing between 0° and 140° over >2000 cycles; record temperature fluctuation and resistance changes.

- Single TPU fiber thermal conductivity measured by thermal bridge method: ~0.28 W m⁻¹ K⁻¹ across samples (S1: 0.286±0.018; S2: 0.280±0.005; S3: 0.278±0.002), similar to bulk TPU.

- Composite thermal conductivity: Selective coating of Ecoflex-BNNSs on patterned TPU grids significantly enhanced k. At 25 wt% BNNSs and ~0.3 mm layer, k reached 0.844 W m⁻¹ K⁻¹, representing a 4442% increase over the pure patterned fibrous structure (0.019 W m⁻¹ K⁻¹). Thermal conductivity remained stable after cycling: max fluctuation 6.4% (bending) and 7.9% (stretching) after 800 cycles at ~100% strain.

- Breathability: Air permeability decreased moderately from 27.54 mm s⁻¹ (pure patterned TPU) to 21.43 mm s⁻¹ (with Ecoflex-BNNSs), while SEM showed pores between grids remained open. Water vapor transmission: weight loss rate of bottles covered with the composite was comparable to uncovered and pure patterned TPU; plastic wrap showed negligible loss after 240 h.

- Mechanical flexibility: Composite maintained excellent flexibility; even with 25 wt% BNNSs, stretchability exceeded 600% due to Ecoflex compliance and strong adhesion at the Ecoflex-BNNSs/TPU interface. No separation after >1000 bending/stretching cycles observed by SEM.

- Device thermal management: For a graphene-based flexible conductor under 10 V, equilibrium surface temperature decreased with higher BNNS loading. With 25 wt% BNNSs, equilibrium temperature was ~45.1 °C vs 68.3 °C with pure Ecoflex encapsulation (34% reduction). Temperature fluctuation during >2000 bending-releasing cycles (0°–140°) was within 0.5 °C; by contrast, strain sensor with pure Ecoflex showed ~3 °C fluctuation, sixfold higher than the 25 wt% BNNSs composite.

- Sensing performance: Graphene-based strain sensor exhibited gauge factor ~1.0 (0°–80°) and ~1.80 (80°–140°) with linear response and stability over >2000 cycles. Breathability preserved (~21.41 mm s⁻¹) with or without graphene.

- Prototype demonstration: Inkjet-printed Ag serpentine conductors on Ecoflex-BNNSs film showed lower surface temperatures than pure Ecoflex under 2.5 V due to higher k. Electrospun fiber side offered additional thermal insulation, suggesting skin-side placement to mitigate burn risk. Device affixed to a doll’s elbow showed stable surface temperature during motion, indicating robust thermal management and electrical stability.

The patterned electrospun TPU architecture, combined with selective Ecoflex-BNNSs coating along grid lines, creates continuous thermally conductive pathways while leaving inter-grid porous regions open for gas and vapor transport. This design overcomes the traditional trade-off between thermal conductivity and breathability/flexibility. BNNSs provide high intrinsic k and electrical insulation, enabling effective heat spreading without electrical interference. The composite maintains mechanical compliance due to Ecoflex’s low modulus and strong interfacial adhesion with TPU fibers, supporting durability under repeated bending and stretching. In device-level tests, rapid heat dissipation through the Ecoflex-BNNSs layer significantly lowers operating temperatures and stabilizes thermal behavior under cyclic deformation, directly addressing thermal management challenges in wearable electronics. The preserved air and water vapor permeability indicates suitability for long-term skin contact applications, minimizing discomfort or irritation.

A simple, scalable route to flexible, breathable composites with advanced thermal management has been demonstrated by coating Ecoflex-BNNSs layers on patterned electrospun TPU fibrous grids. The composite achieves a 4442% increase in thermal conductivity over the pure patterned fibrous structure while largely retaining breathability and excellent flexibility. Integrated devices show markedly reduced equilibrium operating temperatures and minimal temperature fluctuations under prolonged bending cycles, validating robust thermal performance. The approach also supports direct fabrication of wearable electronics with desired architectures (e.g., inkjet-printed conductors) and safe skin-interfacing via the fibrous insulating side. These results provide a feasible path toward next-generation wearable electronics requiring concurrent heat dissipation, flexibility, and permeability.

- BNNS loading above 25 wt% in Ecoflex resulted in viscous mixtures with poor flowability, limiting further increases in filler content and potentially capping achievable thermal conductivity.

- Electrospun TPU fibers (~1 μm diameter) did not benefit from chain-alignment-driven thermal conductivity enhancement seen in ultrathin fibers (<150 nm), constraining matrix k.

- Thermal performance and durability were demonstrated under specific laboratory conditions (e.g., fixed voltages, bending between 0° and 140°, strain ~100%); broader operational environments and long-term in vivo wear conditions were not assessed.

Related Publications

Explore these studies to deepen your understanding of the subject.