Environmental Studies and Forestry

Utilizing cost-effective pyrocarbon for highly efficient gold retrieval from e-waste leachate

K. Fu, X. Liu, et al.

The study addresses the rapidly growing challenge of electronic waste (E-waste), which is expanding at ~4% annually and presents both environmental risks and an urban mining opportunity due to high precious metal content, especially gold (~280 g per ton, often 10–100 times ore grades). Hydrometallurgical pretreatment of E-waste yields leachates with comparatively high Au(III) concentrations (up to ~2000 mg L⁻¹), creating an ideal stream for selective and efficient recovery. Conventional techniques (solvent extraction, electrochemical reduction) can be laborious, costly, and reagent-intensive, while adsorption offers low cost, operational simplicity, and minimal secondary pollution. However, traditional sorbents (silica, activated carbon, resins) suffer from poor selectivity in complex matrices, structural instability, and functional group loss. Advanced sorbents (porous polymers, metal-based nanocrystals) show promise but often entail expensive, low-yield syntheses and generate waste streams, undermining scalability and economics. Pyrocarbon from renewable biomass is abundant, cost-effective, and self-functionalizing, with inherent redox-active moieties and graphitic domains that could act as electron donors for Au(III) reduction. Yet, the structure–function relationships, electron sources, and reduction mechanisms in pyrocarbon remain insufficiently understood, limiting practical deployment. This work aims to design an alginate-derived pyrocarbon with optimized carbon hybridization and functionality (via pyrolysis temperature control) to achieve high-capacity, selective, and economically viable gold recovery from E-waste leachates, and to elucidate the mechanistic pathways of electron donation/transfer and stepwise nucleation during Au(III) reduction.

Previous efforts have explored pyrocarbon-based materials for gold extraction, including activated carbon, carbon nanotubes, biochar, and graphene oxide, focusing on porosity and functional groups (e.g., phenolic hydroxyls, sulfhydryls). Traditional sorbents struggle with selectivity and stability in complex leachates, while advanced adsorbents (porous polymers, MOFs/COFs, metal sulfides, metal-based nanocrystals) have improved performance but face scale-up barriers due to complex, costly syntheses and waste generation. Literature suggests pyrocarbon can reduce Au(III) via phenolic/quinone redox couples and that graphitic domains in high-temperature pyrocarbon possess reductive activity and conductivity, potentially mediating electron transfer. However, incomplete understanding of the structure–function relationships, electron sources, and reduction processes has limited optimization and practical application for gold recovery.

Sorbent preparation: Sodium alginate (SA, 1.0 wt%) was dropped into 2.0 wt% CaCl₂ to form Ca²⁺-alginate gels, cured 12 h, freeze-dried, pre-carbonized at 300 °C (2 h), then pyrolyzed under Ar at 500, 600, 700, or 800 °C (2 h, 5 °C min⁻¹) to yield PyC500–PyC800. Post-pyrolysis acid wash with 2 M HCl removed Ca species; products were rinsed and freeze-dried. Characterization: SEM/TEM/HRTEM for morphology and lattice planes; BET/SSA and pore size distribution; XRD for crystallinity; ATR-FTIR and Raman for functional groups and carbon structure; XPS for C 1s/O 1s and sp²/sp³ ratios, O/C ratios; electrical conductance via Quantum Design PPMS; in situ FTIR to track interfacial evolution; OCPT electrochemical measurements; Au L₃-edge XANES/EXAFS at the Australian Synchrotron (transmission mode) with LCF and EXAFS fitting (Demeter Athena/Artemis); ICP-MS for metal concentrations. Batch adsorption/performance tests: Au(III) stock from HAuCl₄; kinetics at 10 and 50 mg L⁻¹; isotherms at 10, 25, 60 °C; pH effects (pH 1–8; also 0.5–1.0 M HCl); ionic strength/co-ion effects with common cations (Al³⁺, Fe³⁺, Ni²⁺, Cu²⁺, Zn²⁺) and anions (F⁻, Cl⁻, Br⁻, I⁻, HCO₃⁻, SO₄²⁻, PO₄³⁻); tests on AuBr₄⁻, Au(CN)₂⁻, and Au(S₂O₃)₂³⁻. Default conditions: pH ~3.0, 12 h, 0.5 g L⁻¹ sorbent, 20 mL volume, 180 rpm, 25 °C unless specified. Langmuir and mass transfer models applied; thermodynamics via Van’t Hoff. Real leachates: CPU boards (AMD, Intel) were crushed (>20 mesh) and leached using aqua regia (Aqua) or N-bromosuccinimide/pyridine (NBS-Py) to obtain AMD-Aqua, AMD-Aqua*10 (10× diluted), AMD-NBS, Intel-Aqua, Intel-NBS. For recovery, 0.05 g PyC700 in 50 mL leachate at 25 °C, 180 rpm, 12 h; filtrate analyzed by ICP-MS. Gold purification: Au-loaded PyC700 (100 mg) was calcined in air at 900 °C (2 h, 10 °C min⁻¹), cooled, then rinsed twice with concentrated HCl (6 h each), washed with DI water and tested for purity (GB/T 38145-2019). Electrochemical analyses: Three-electrode setup (pyrocarbon-modified glassy carbon working electrode; Ag/AgCl reference; Pt counter) for OCPT and electron donating/accepting capacity tests. Theoretical calculations: Spin-polarized DFT (VASP, PBE-GGA, D3 dispersion). 5×5×1 graphene supercells with hydroxyl groups; initial adsorption with HAuCl₄ (for +3 Au), subsequent steps with AuCl₃ due to facile HCl loss; ≥15 Å vacuum; energy/force tolerances 2×10⁻⁵ Ha and 0.004 Ha Å⁻¹; adsorption energies Ead=ET−EG−EAu; reaction free energies referenced to 1/2 H₂ and potential U (Nørskov/Bockris formalism). Bader charge and ELF analyses used to assess electron delocalization and deprotonation tendencies of O-functional groups. Techno-economic analysis (TEA): Process flow, costs (CPU purchase, sorbent production, labor, operations), revenue, and sensitivity analyses conducted per guidelines for adsorption TEA, benchmarking input-output ratios and cost contributors.

- Pyrocarbon optimized at 700 °C (PyC700) showed the highest theoretical Au(III) adsorption capacity Qm = 2829.7 mg g⁻¹ and mass transfer coefficient k ≈ 1.73 × 10⁻⁶ m s⁻¹ at 25 °C; equilibrium achieved in <30 min at 10–50 mg L⁻¹ Au(III) with ~100% removal.

- Temperature enhanced capacity: Qm reached 6368.4 mg g⁻¹ at 60 °C (endothermic process; ΔG° < 0, ΔH° > 0).

- Broad-condition robustness: >99.5% recovery at 10 mg L⁻¹ across pH 1–8; at 1000 mg L⁻¹, capacities >3040.4 mg g⁻¹ (pH 3–8) and >2801.0 mg g⁻¹ in 0.5–1 M HCl. At trace levels, recovery efficiencies were >92.2% (50 μg L⁻¹) and >96.8% (100 μg L⁻¹).

- Selectivity and anti-interference: Strong resistance to competing cations (Al³⁺, Fe³⁺, Ni²⁺, Cu²⁺, Zn²⁺) and anions (F⁻, Cl⁻, Br⁻, I⁻, HCO₃⁻, SO₄²⁻, PO₄³⁻). Distribution coefficient for Au(III) Kd ≈ 3.1 × 10⁶ mL g⁻¹, 5–7 orders of magnitude above competing ions; abstract reports selectivity Kₐ = 3.1 × 10⁸ mL g⁻¹. Selectivity correlated with metal ion reduction potentials; minor Fe(III) reduction to Fe(II) observed.

- Complexing-ligand effects: Qm decreased by 66.9% for AuBr₄⁻, and by 91.1% and 95.7% for Au(S₂O₃)₂³⁻ and Au(CN)₂⁻, respectively, consistent with lower reduction potentials and higher complex stability (lgK).

- Real leachates: AMD-Aqua (Au 1330.1 mg L⁻¹, pH<0) showed limited recovery (42.5%, qe 1120.7 mg g⁻¹); after 10× dilution (AMD-Aqua*10), nearly 100% recovery with residual ~0.1 μg L⁻¹. AMD-NBS (650.2 mg L⁻¹) achieved >99.97% recovery (residual 0.132 mg L⁻¹). Intel leachates (12.65 and 2.60 mg L⁻¹) achieved >99.96% recovery.

- Product purity: Recovered gold purity >99.82% (23.96 karat) after simple calcination and HCl rinsing, despite high co-ion concentrations.

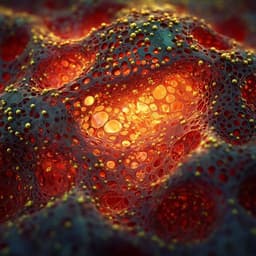

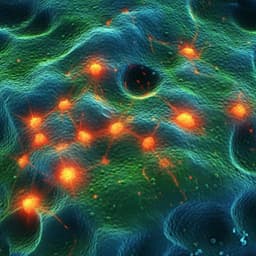

- Mechanism: Electron donation originates primarily from unsaturated sp² aromatic domains undergoing hydroxylation (water-derived phenolic –OH formation) and subsequent oxidation. In situ FTIR showed concurrent increases in phenolic –OH and adsorbed water signals; XPS indicated increasing O/C and decreasing sp²/sp³ ratios during uptake.

- Nucleation pathway: Time-resolved XANES/EXAFS evidenced initial Au–Cl coordination and progressive shift to Au–Au interactions, indicating chlorine-protected gold cluster intermediates. DFT revealed unfavorable direct full dechlorination (barrier +1.08 eV) but favorable stepwise adsorption/dechlorination forming AuₙClₘ clusters (e.g., G·Au₁₅Cl₁₄) with progressively exothermic steps (overall down to −21.84 eV), rationalizing rapid reduction and growth.

- TEA: Annual income US$1.2×10⁶ vs annual input US$8.7×10⁴; input-output ratio ~1370%. Major cost: CPU purchase (65.04%); sorbent production ~10.38%. Raising adsorption temperature to 60 °C reduced specific cost by 19.2%, increasing input-output ratio to ~1692%.

The tailored alginate-derived pyrocarbon achieves high-capacity, fast, and selective gold recovery from complex aqueous matrices and real CPU leachates, directly addressing the need for scalable, low-cost, and environmentally friendly methods. The dominance of chemical reduction over electrostatic attraction explains robust performance across wide pH and ionic strengths. Selectivity aligns with reduction potential trends, enabling discrimination against common co-ions and minimizing side reductions (limited Fe(III)→Fe(II)). Mechanistic investigations integrate operando spectroscopy and DFT to show that delocalized π-electrons from sp² aromatic domains are mobilized via water-driven hydroxylation, creating phenolic –OH that donate electrons for Au(III) reduction. The proposed stepwise nucleation via Au–Cl clusters lowers energy barriers, facilitating rapid formation and growth of Au nanoparticles, consistent with XANES/EXAFS observations of decreasing Au–Cl and increasing Au–Au coordination. Economically, the sorbent’s low-cost synthesis and high performance yield a strong input-output ratio, with sensitivity analysis indicating further gains via temperature-boosted capacity. Overall, the findings validate pyrocarbon as a practical platform for selective urban gold mining and point to design rules—balancing graphitization, functionality, and conductivity—to maximize performance.

This work presents an eco-friendly, alginate-derived pyrocarbon (PyC700) that delivers exceptionally high Au(III) recovery capacities (up to 2829.7 mg g⁻¹ at 25 °C and 6368.4 mg g⁻¹ at 60 °C), near-quantitative removal across broad pH and ionic conditions, and strong selectivity against competing ions. It efficiently treats real CPU leachates, yielding high-purity gold (>99.82%, 23.96 karat) via simple calcination and acid rinsing. Mechanistic elucidation identifies unsaturated aromatic sp² carbon as the primary electron source facilitated by hydroxylation, and reveals a stepwise nucleation mechanism through Au–Cl cluster intermediates that lowers reduction barriers and accelerates nanoparticle growth. TEA confirms substantial economic potential with an input-output ratio of ~1370%, improving with higher operating temperatures. Future work could optimize performance in oxidizing highly acidic leachates without dilution, broaden applicability to strongly complexed Au species (e.g., cyanide/thiosulfate systems), and scale manufacturing while preserving the optimized structural/electronic features.

- Performance is significantly reduced in extremely acidic, strongly oxidizing leachates (e.g., undiluted AMD-Aqua, pH<0), necessitating dilution to achieve near-quantitative recovery.

- Marked capacity losses occur for strongly complexed Au species such as Au(CN)₂⁻ and Au(S₂O₃)₂³⁻ (reductions of ~95.7% and ~91.1%, respectively), reflecting dependence on reduction potential and complex stability.

- Minor reduction of Fe(III) to Fe(II) indicates limited but present side reactions driven by redox potential differences.

- TEA sensitivity highlights dependence on CPU feedstock costs and labor; improvements may be constrained by market/regulatory factors.

Related Publications

Explore these studies to deepen your understanding of the subject.