Engineering and Technology

Tough, anti-freezing and conductive ionic hydrogels

S. Wu, T. Wang, et al.

Wearable electronics for daily activities, sports, medical treatments, and entertainment require soft conductive materials with excellent mechanical performance and high ionic conductivity. Conductive ionic hydrogels are attractive due to their solid-like mechanics and liquid-like ion transport, but they freeze below 0 °C, causing loss of conductivity and stretchability and limiting use in low-temperature environments. Existing antifreezing strategies using organic solvents and salts often reduce conductivity (due to low salt solubility and suppressed dissociation in water–organic mixtures) and can be environmentally and health hazardous. High-salt approaches can improve conductivity and freeze tolerance but may compromise mechanical properties via salting-in effects. Therefore, the research question is how to create hydrogels that simultaneously achieve toughness, high conductivity, and robust antifreezing performance without sacrificing mechanical properties. The study proposes using potassium acetate (KAc) to induce a salting-out effect in PVA to strengthen hydrogels while leveraging KAc’s high solubility and strong freezing-point depression to deliver antifreezing, conductive hydrogels.

Prior work to address hydrogel freezing has introduced organic solvents (e.g., glycerol, propylene/ethylene glycol) combined with salts to depress freezing, but salts precipitate at low temperatures due to limited solubility in organic media and salt dissociation is suppressed, reducing conductivity. Organic solvents also raise environmental, health, and safety concerns. High-salt content hydrogels (e.g., CaCl2 in polyacrylamide–alginate double networks) can yield high conductivity and freeze tolerance, yet increasing concentrations of salting-in salts (e.g., CaCl2, NaNO3, NaI) often weaken hydrogels by increasing polymer solubility. The Hofmeister series describes ion-specific salting-in/out effects: salting-out salts (e.g., Na2SO4, Na2CO3) strengthen PVA by promoting polymer aggregation but may have limited solubility; salting-in salts tend to soften gels but are more soluble. The ideal is a salt with both high solubility and a salting-out effect. The study identifies KAc as such a candidate, hypothesizing it can deliver both mechanical reinforcement and antifreezing performance without sacrificing conductivity.

Materials and fabrication: 10 wt% aqueous PVA solutions (various molecular weights: 27 kDa, 89 kDa, 195 kDa) were poured into molds, frozen at -20 °C to fix shape and prepack chains, then immersed (freeze–soak method) into KAc solutions of varying concentrations (10–50 wt%). During soaking at room temperature, ice within the frozen PVA melted into the salt solution; K+ and Ac− ions induced a salting-out effect, expelling hydration water and promoting hydrogen bonding among PVA hydroxyls, leading to chain aggregation/crystallization and gel formation. Soaking time for mechanical tests was 96 h. The salting-out behavior was contrasted with CaCl2 where PVA remained dispersed. Characterization: (1) Mechanical testing: Tensile stress–strain tests were performed on hydrogels prepared from 10 wt% PVA across KAc concentrations (10–50 wt%) and PVA molecular weights (27, 89, 195 kDa), extracting tensile strength and toughness. SEM was used to observe microstructure versus KAc concentration (10, 30, 50 wt%). (2) Thermal analysis: Differential scanning calorimetry (DSC) measured freezing temperatures of hydrogels treated with 0–50 wt% KAc and compared them to the KAc solution phase diagram. A simple visual test assessed 50 wt% KAc solution transparency after storage at -60 °C for 1 h. (3) Electrical characterization: Ionic conductivity was measured with an electrochemical workstation on hydrogels soaked at 10, 30, and 50 wt% KAc at room temperature; temperature-dependent conductivity was measured from 20 °C to -60 °C for 50 wt% KAc-treated PVA gels. Relative resistance changes versus strain were recorded. An LED circuit demonstrated conductive performance at -30 °C for gels with and without KAc during bending/stretching. (4) Generality tests: PAAm and PHEA hydrogels were UV-polymerized and soaked in 50 wt% KAc for 5 h; their tensile strength and toughness before/after soaking were measured. Visual imaging documented transparency/appearance changes. Anti-dehydration capacity was noted qualitatively for KAc-containing gels.

- KAc induces a salting-out effect on PVA, causing polymer aggregation and gel formation; in contrast, CaCl2 promotes PVA dispersion (salting-in).

- KAc exhibits high solubility and strong freezing-point depression: 50 wt% KAc solution remained transparent at -60 °C for 1 h; the solution phase diagram shows freezing temperatures as low as approximately -70 °C at 50 wt%.

- Mechanical enhancement with KAc concentration (10 wt% PVA, Mw = 89 kDa, 96 h soak): tensile strength increased from 0.1 MPa (10 wt% KAc) to 4.0 MPa (50 wt% KAc); toughness increased from 0.1 MJ/m³ to 7.8 MJ/m³.

- Mechanical enhancement with PVA molecular weight (50 wt% KAc soak): tensile strength rose from 0.5 MPa (27 kDa) to 8.2 MPa (195 kDa); toughness increased from 0.1 MJ/m³ to 25.8 MJ/m³. The 195 kDa PVA gel could lift a heavy load (visual demo).

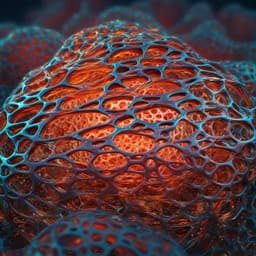

- Microstructure densification: SEM showed decreasing pore size and denser fibrous structures as KAc concentration increased from 10 wt% to 50 wt%.

- Antifreezing performance: DSC revealed freezing temperatures of KAc-treated hydrogels decreased from 0 °C (0 wt% KAc) to below -70 °C (50 wt% KAc), even lower than corresponding KAc solutions, attributed to synergy between polymer confinement and colligative effects.

- Conductivity: room-temperature conductivity increased with KAc concentration from 5.2 S/m (10 wt%) to 8.0 S/m (50 wt%). For 50 wt% KAc-treated hydrogels, conductivity declined with temperature from 8.0 S/m at 20 °C to 1.2 S/m at -60 °C. LED tests at -30 °C showed KAc-treated gels remained soft and conductive during deformation, whereas non-salted gels froze and fractured.

- Strain sensing: relative resistance change of 50 wt% KAc-treated PVA hydrogel increased linearly with strain.

- Generality: soaking in 50 wt% KAc for 5 h substantially toughened other polymers. PHEA strength increased from 5.7 kPa to 306.5 kPa; toughness from 2.2 kJ/m³ to 1298.2 kJ/m³. PAM (PAAm) strength increased from 73.9 kPa to 337.6 kPa; toughness from 20.6 kJ/m³ to 1303.2 kJ/m³. Hydrogels with KAc also exhibited notable anti-dehydration capacity.

- Overall, 50 wt% KAc-treated PVA hydrogels combined high toughness (25.8 MJ/m³), high strength (8.2 MPa), high conductivity (8.0 S/m at 20 °C; 1.2 S/m at -60 °C), and freeze tolerance below -60 °C, outperforming many reported antifreezing conductive hydrogels.

The study demonstrates that KAc uniquely provides both high solubility and a strong salting-out effect on PVA, enabling simultaneous mechanical reinforcement and antifreezing performance without compromising conductivity. The freeze–soak process prepackages PVA chains and, upon immersion in concentrated KAc, ions polarize hydration water and increase interfacial tension around polymer backbones, expelling water and facilitating interchain hydrogen bonding and crystallization. This results in denser microstructures and significantly higher strength and toughness, with enhancements scaling with both KAc concentration and polymer molecular weight. The hydrogels’ freezing temperatures fall below those of corresponding KAc solutions, likely due to polymer network confinement synergizing with colligative depression. Electrical measurements confirm that high-salt loading maintains high ionic conductivity at room temperature and preserves functional conductivity at subzero temperatures, enabling reliable operation (e.g., powering LEDs) at -30 °C and beyond. The method generalizes to other hydrophilic polymer networks (PAAm, PHEA), where brief soaking yields order-of-magnitude increases in strength and toughness. The gels also show improved anti-dehydration behavior, important for durability in low humidity. Collectively, the approach offers a simple, scalable route to tough, highly conductive, and antifreezing hydrogels suitable for soft electronics, ionic skins, sensors, and soft robotic components.

This work introduces a simple freeze–soak strategy using potassium acetate to fabricate tough, antifreezing, and conductive ionic hydrogels. KAc induces a salting-out effect that aggregates polymer chains and strengthens networks while its high solubility ensures strong freezing-point depression and high ionic conductivity. PVA hydrogels treated with 50 wt% KAc achieve tensile strength of 8.2 MPa, toughness of 25.8 MJ/m³, conductivity of 8.0 S/m at 20 °C (1.2 S/m at -60 °C), and remain unfrozen below -60 °C. The approach generalizes to PAAm and PHEA, delivering up to two orders of magnitude increases in toughness, and imparts anti-dehydration capacity. These combined features position the hydrogels for broad use in soft aqueous batteries, wearable sensors, ionic skins, and soft robotics. Potential future research directions include: optimizing ion species and concentrations to further tailor mechanical/electrical performance and freezing resistance; exploring additional polymer chemistries and network architectures; investigating long-term stability, dehydration resistance, and fatigue under cyclic loading and extreme environments; assessing biocompatibility and safety for wearable/implantable applications; and integrating these hydrogels into functional devices to evaluate real-world performance.

Related Publications

Explore these studies to deepen your understanding of the subject.