Engineering and Technology

Strong, tough, ionic conductive, and freezing-tolerant all-natural hydrogel enabled by cellulose-bentonite coordination interactions

S. Wang, L. Yu, et al.

The study addresses the long-standing challenge of creating cellulose-based hydrogels that simultaneously exhibit high mechanical robustness and high ionic conductivity. Conventional addition of inorganic salts to achieve conductivity weakens cellulose’s hydrogen-bond network, compromising mechanical strength. The authors hypothesize that incorporating bentonite (BT) nanoplatelets can form strong coordination bonds (Al–O–C) with cellulose, establishing a reinforced network while also modulating ion transport within nanoconfined interlayers. The goal is to realize an all-natural, low-cost, sustainable hydrogel with strong, tough, highly conductive, and freezing-tolerant properties suitable for flexible electronics and biosensors.

Prior works achieved conductive hydrogels using synthetic polymers or modified celluloses, often trading off mechanical strength when salts are introduced. Strategies like double networks, organohydrogels, and salt-in hydrogel electrolytes improve either strength or low-temperature conductivity but not both simultaneously for cellulose systems. Comparative analysis (Fig. 1e) positions the cellulose/BT hydrogel favorably against methyl cellulose/PAMPS, cellulose/BzMe2NOH, EG-waPUA/PAAm, CSMA/PAA, and PAAm/ZnSO4/LiCl hydrogels in compressive strength, sustainability, cost, freezing temperature, and ionic conductivity at room temperature and −20 °C. Bentonite and layered clays have previously reinforced polymer nanocomposites and provided ion pathways; however, direct coordination bonding with cellulose to counteract salt-induced weakening had not been fully exploited.

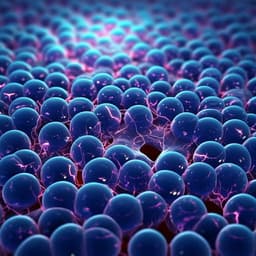

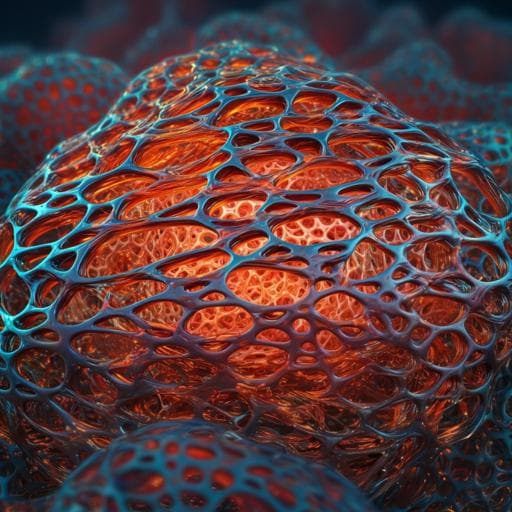

Materials: Biomass cellulose extracted from poplar; BT nanoplatelets via mechanical exfoliation; cross-linker 1,4-butanediol diglycidyl ether (BDE); LiCl as electrolyte salt; standard reagents and DI water. Extraction of cellulose: Poplar powders treated in 5 wt% NaOH at 70 °C for 4 h to remove hemicellulose/lignin, washed with water and ethanol. Further bleaching with 2 wt% NaClO2 and acetic acid at 60 °C for 4 h; washed to neutral and vacuum-dried to obtain cellulose pulp. Hydrogel preparation: Cellulose solution (3 wt%) prepared in 7 wt% NaOH/12 wt% urea aqueous solvent at −12 °C. BT (0.3 g per 100 g cellulose solution) and BDE (0.75 g) added to cellulose solution, mixed, degassed, molded, and cured at 60 °C for 2 h to gel. Gels immersed in DI water for 3 days to obtain cellulose/BT hydrogels, then soaked in 2 M LiCl for 24 h to obtain ionic conductive cellulose/BT (Ion-CB) hydrogels. Control samples included cellulose-only and cellulose/BT without LiCl and with/without BDE cross-linker. Characterization: CLSM for pore structure; TEM/SEM/FESEM and EDS for morphology and elemental mapping; XRD for crystalline structure and BT interlayer spacing; FTIR to detect Al–O–C bond (peak at 845 cm−1); solid-state 27Al and 13C MAS NMR for aluminum coordination states and cellulose crystallinity; XPS (Al 2p) for AlTd to AlOh transformation; rheology of cellulose/BT solution (sol–gel transition by G′/G″ crossover); Raman mapping (OH stretching) for cross-link density distribution. ICP-OES measured LiCl content. DFT simulations: VASP with PBE-GGA and PAW, cutoff 520 eV, 3×3×1 k-grid. Calculated binding energies for cellulose–cellulose and cellulose–BT interactions in vacuum, water, and LiCl/H2O environments. Evaluated hydrolysis energetics of Al–O–C to Al–OH. Mechanical testing: Compressive and tensile tests on cylindrical samples (10 mm diameter × 10 mm height) using UTM at 2 mm min−1; cyclic compression up to 50% strain for 10 cycles; modulus from initial linear stress–strain region; reswelling tests after freeze-drying; pH influence studied by acidic/alkaline treatments. Thermal/phase behavior: DMA (G′, G″) from 25 to −90 °C and DSC from 25 to −45 °C to determine freezing points. Electrochemistry: EIS (10–10^5 Hz, 0.1 V) at temperatures from 25 to −20 °C; conductivity σ = L/(RA) with defined sample geometry; LED demonstration under bending/twisting at ambient and −20 °C; sensor demonstrations for motion/physiological signals.

- Structure and bonding: XRD shows BT basal reflection shifts from 7.2° to 5.6° in Ion-CB indicating increased interlayer spacing due to cellulose intercalation. FTIR exhibits a new 845 cm−1 peak evidencing Al–O–C bond formation. 27Al MAS NMR indicates decreased AlTd/AlOh ratio in cellulose/BT, consistent with coordination of cellulose O with BT Al sites. XPS Al 2p reveals binding energy shifts supporting AlTd to AlOh transformation. Raman mapping shows high cross-link density in Ion-CB with or without BDE, much higher than cellulose-only hydrogel.

- Rheology: Cellulose/BT solution undergoes rapid sol–gel transition (G′ > G″) within 7 min; cellulose solution without BT shows no such transition, evidencing BT-induced network formation.

- DFT: Cellulose–cellulose binding energy weakens in LiCl/H2O (−0.459 eV). Cellulose–BT binding energy is strong: −5.435 eV (vacuum), −6.792 eV (H2O), −6.409 eV (LiCl/H2O), an order of magnitude stronger than cellulose–cellulose, validating robust Al–O–C cross-linking even with salts and across pH.

- Mechanical performance: Ion-CB hydrogel achieves compressive strength up to 3.2 MPa at 80% strain (18.9× higher stress and 1.5× higher fracture strain than ionic cellulose without BT). Tensile fracture stress 0.76 MPa at 96% strain; fracture energy 0.45 MJ m−3. Compressive modulus increased 12× and fracture energy 23× versus ionic cellulose without BT. Cyclic compression (50% strain) shows near-overlapped curves from 2nd–10th cycles and recovery to peak stress, indicating robust coordination networks; cellulose-only ionic hydrogel shows progressive stress decay.

- Resilience and recovery: Hydrogels withstand bending, impact, and local cutting without damage; reswelled freeze-dried Ion-CB recovers mechanical properties nearly identically to original.

- pH effect: Acidic/alkaline treatments cause only slight decreases in strength, modulus, and toughness, consistent with mild weakening of Al–O–C.

- Ionic conductivity: Cellulose hydrogel without LiCl is non-conductive; cellulose/BT without LiCl shows ~1 mS cm−1, indicating BT-mediated ion environment. Ion-CB (with 2 M LiCl) delivers 89.9 mS cm−1 at 25 °C, ~19% higher than ionic cellulose without BT; introduction of BDE does not reduce ion mobility. At −20 °C, Ion-CB maintains 25.8 mS cm−1.

- Freezing tolerance: DMA/DSC show freezing points of −14.1 °C (cellulose/BT) and −28.9 °C (Ion-CB). G′ and G″ remain largely stable down to ~−30 °C for Ion-CB, indicating anti-freezing behavior due to LiCl. Mechanical properties remain desirable at −20 °C.

- Mechanism: Synergy of strong cellulose–BT Al–O–C coordination mitigates salt-induced weakening; LiCl depresses freezing point by disrupting water H-bonding; negatively charged cellulose/BT interlayers act as fast cation transport channels, enhancing conductivity.

- Application demo: Ion-CB hydrogel conducts and lights LEDs under flat, bent, and twisted states at 25 °C and −20 °C; wearable sensor tests show reproducible resistance responses for motions, including at −20 °C.

The work demonstrates that introducing BT nanoplatelets into cellulose hydrogels establishes strong coordination cross-links (Al–O–C) that offset the deleterious effect of dissolved salts on cellulose’s hydrogen-bond network. This preserves and enhances mechanical strength and toughness while enabling high ionic conductivity. The layered BT–cellulose intercalated structure modulates ion distributions and provides nanoconfined pathways that facilitate cation transport, explaining the conductivity gains even at high cross-link density and at subzero temperatures. LiCl depresses the freezing point, maintaining a soft, conductive network well below 0 °C. Collectively, the design resolves the key trade-off between mechanical robustness and ionic transport in cellulosic hydrogels. The demonstrated stability under cyclic loading, resilience after severe deformation, recovery after freeze-drying, and reliable performance at −20 °C underscore the hydrogel’s suitability for flexible electronics and biosensing in harsh environments.

An all-natural cellulose/bentonite hydrogel was designed that integrates strong Al–O–C coordination bonding and nanoconfined ion pathways to achieve a rare combination of high strength and toughness with high ionic conductivity and freezing tolerance. The hydrogel exhibits compressive strength up to 3.2 MPa, tensile fracture stress of 0.76 MPa at 96% strain, fracture energy of 0.45 MJ m−3, room-temperature ionic conductivity of 89.9 mS cm−1, and maintains 25.8 mS cm−1 at −20 °C with a depressed freezing point of −28.9 °C. The facile, scalable process and sustainable, abundant components (cellulose, BT) suggest strong potential for practical applications in flexible and wearable electronics, sensors, and energy devices. Future research could optimize ion species and concentrations, explore other layered minerals or multivalent coordination sites, assess long-term durability and biocompatibility, and integrate the hydrogel into device architectures for multifunctional performance.

Ionic conductivity decreases with temperature as expected, although it remains high at −20 °C. Mechanical and ionic properties depend on the presence of LiCl; performance without salts is lower. Acidic or alkaline environments cause a slight decrease in mechanical properties, indicating some sensitivity of coordination interactions. The study does not report long-term aging, dehydration resistance over extended cycles, or comprehensive biocompatibility/toxicity assessments, which may affect generalizability to specific biomedical applications.

Related Publications

Explore these studies to deepen your understanding of the subject.