Medicine and Health

Strenuous exercise-tolerance stretchable dry electrodes for continuous multi-channel electrophysiological monitoring

R. Xie, Q. Li, et al.

Discover groundbreaking research on a nano-thick porous stretchable dry electrode system that excels in electrophysiological monitoring during strenuous exercise, even amidst perspiration. Conducted by Ruijie Xie and colleagues, this innovative approach promises to enhance health monitoring, prosthetics, and human-machine interfaces.

~3 min • Beginner • English

Introduction

The study addresses the challenge of reliably acquiring electrophysiological (EP) signals—EMG, ECG, and EEG—during strenuous exercise, which involves rapid, dynamic skin motion (acceleration, deceleration, stretching, vibration) and profuse sweating. Conventional gel electrodes suffer from dehydration and skin irritation during long-term use, while most dry electrodes either mitigate motion artifacts or allow perspiration but not both simultaneously. The research question is how to design a dry, stretchable, breathable electrode that forms a stable electrode–skin interface to enable continuous, multi-channel EP monitoring under severe motion and sweating. The work’s purpose is to develop and validate an ultrathin, porous, stretchable dry electrode system with strong conformity and water vapor permeability to maintain interface stability and comfort, thereby supporting healthcare monitoring, prosthetic control, and human–machine interfaces in real-world exercise scenarios.

Literature Review

Prior studies enhanced dry electrode performance against motion artifacts using ultra-thin self-adhesive films (<300 nm), microstructured (gecko-inspired) adhesives, and in-situ formed electrodes to improve adhesion and conformity (Someya; Jeon; Yu). To improve comfort and performance under sweating, gas-permeable and porous substrates such as porous films, leather, textiles, and electrospun mats have been explored. However, existing dry electrodes typically address either movement or sweating independently and do not maintain stable EP acquisition during combined strenuous motion and heavy perspiration. This gap motivates the development of a nano-thick, porous, stretchable electrode that simultaneously offers strong skin conformity/adhesion, high stretchability, and high water vapor permeability.

Methodology

Electrode design and fabrication:

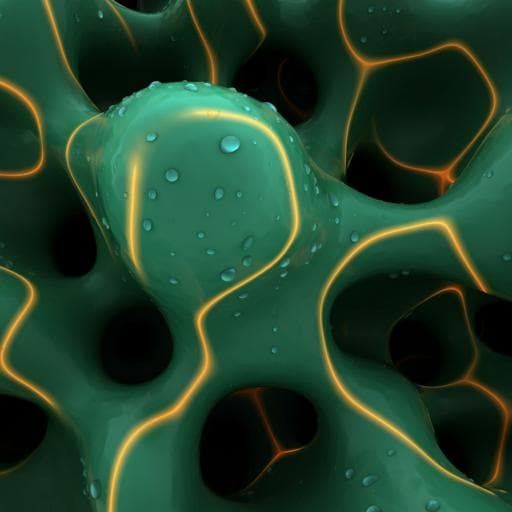

- Ultranthin porous stretchable substrate: A one-step Marangoni-effect-based method forms an ultrathin SEBS film. A 20 µL droplet of SEBS in toluene is placed on an aqueous NaCl solution (optimized at 5 wt% NaCl) in a fume hood. The lower surface tension enables spreading; as toluene evaporates, SEBS concentration rises, decreasing surface tension and increasing viscosity, driving Marangoni flows that generate pores while viscosity growth limits pore enlargement. Evaporation rate is tuned by wind speed to control pore size (e.g., ~0.8 mg cm−2 min−1 yields 400–1000 µm pore diameter; ~1.4 mg cm−2 min−1 yields 50–110 µm; ~8 mg cm−2 min−1 yields no pores). SEBS thickness is controlled via solution concentration (1–11 wt% SEBS gives ~22–790 nm; thinnest stable freestanding films ~100 nm). Surface tension of water was tuned via NaCl concentration to achieve uniform spreading and homogeneous thickness.

- Conductive layer: Gold is magnetron-sputtered (TWS-300) onto the SEBS porous film to form the ultrathin electrode. A patterned PET mask defines electrode geometry. Optimal Au thickness ~17 nm for stretchability.

- Encapsulation and site definition: A non-porous ultrathin SEBS film is laminated for encapsulation; filter paper masks expose sensing pads by peeling after lamination, leveraging SEBS self-adhesiveness.

- Release: Films are supported on a silicon wafer with a sodium polystyrene sulfonate sacrificial layer; after processing, electrodes are released by dissolving PSS in deionized water.

Connector design:

- To bridge soft electrodes to rigid electronics, a flexible conductive medical dressing (CMD) is bonded to a flexible printed circuit board (FPCB) via anisotropic conductive films (ACF). CMD is first adhered to skin; the ultrathin electrode couples to skin and CMD via Van der Waals forces, forming stable electrode–skin and electrode–connector interfaces.

Mechanical/electrical characterization:

- Stretching behavior and resistance: Tensile tests (AG-X Plus 100N) with in situ resistance (Keithley 2000) quantify stretchability; microcrack formation in Au maintains conductivity up to ~120% strain for optimal Au thickness.

- Electrode-skin impedance: Two 1.5 cm diameter circular electrodes placed 10 cm apart on the forearm; impedance measured across frequencies under 0–14% skin stretch.

- Adhesion force: An ultrathin electrode on skin is coupled to a PET disc (1 cm diameter) via double-sided adhesive; pull-off force measured with tensile tester to determine adhesion.

- Water vapor transmission rate (WVTR): ASTM E96-95 gravimetric method at 20 °C; electrode covers a bottle opening and water mass loss yields WVTR = G/(tA).

- Sweat rate (SR): After 30 min running, pre-weighed tissue squares applied for 5 min to leg, chest, forehead; SR = M/(tA).

EP signal acquisition under motion/sweating:

- EMG: Ultrathin electrodes on arm or leg with gel reference and right leg drive. Tests include dynamic skin stretching (0–14%), arm swings (2 g and 10 g acceleration), pressing skin/electrode, vibration, twisting, and treadmill running at 3 and 6 km h−1. High-density EMG arrays (8 channels) fabricated and evaluated; multi-cycle stretch stability measured to 1000 cycles at 30% strain.

- ECG: Electrodes on chest with reference on belly and right leg drive on right leg. Signals recorded at rest, during squatting, walking, and under sweating (after 30 min run; SR ~3.2 mg cm−2 min−1).

- EEG: Electrodes on forehead with references behind ears. Eyes-open/eyes-closed tasks pre- and post-sweating (after 30 min run; SR ~2.6 mg cm−2 min−1). Alpha rhythm analysis (7–15 Hz) performed.

- Thermal/comfort assessments: Infrared thermography (Fluke TiX580) tracks temperature changes of porous 200 nm electrode, nonporous ultrathin SEBS electrode, and gel electrodes during exercise and sweating; visual inspection of skin texture/redness pre/post wear.

Key Findings

- Fabrication and material performance:

- One-step Marangoni method yields ultrathin porous SEBS films with controllable pore sizes via evaporation rate and uniformity via aqueous surface tension tuning (5 wt% NaCl optimal).

- Gold-coated ultrathin porous electrodes achieve optimal stretchability (~120% strain) at ~17 nm Au due to controlled microcrack formation maintaining conductivity; resistance increases only at extreme strain when percolation paths break.

- After 1000 cycles at 30% strain, electrodes maintain low resistance and good stretchability, indicating robust cyclic durability.

- Water vapor permeability (WVTR) of porous 200 nm electrode is ~25.3 g h−1 m−2, approximately five times higher than typical transepidermal water loss (5–10 g h−1 m−2), outperforming nonporous ultrathin and 1 µm spin-coated SEBS electrodes.

- Electrode–skin impedance remains stable with skin stretching from 0% to 14%.

- Interface stability and connector:

- 200 nm-thick electrodes adhere conformably to skin via Van der Waals forces and stretch with skin, maintaining skin texture and avoiding bubbles; thicker electrodes (1 µm, 5 µm, 90 µm) slip or fail under motion.

- A CMD–ACF–FPCB connector forms a stable electrode–connector interface while preserving flexibility and breathability.

- EMG performance under strenuous motion and sweating:

- High-density 8-channel EMG arrays function during dynamic skin stretching (0–14%), arm swinging (2 g), pressing, vibration, twisting, and treadmill running.

- During running at 6 km h−1 (peak acceleration ~10 g), the ultrathin porous electrode records EMG comparable to gel electrodes; at 3 km h−1 (peak ~6 g) performance is also comparable.

- Under heavy sweating (post 30 min run; arm SR ~2.8 mg cm−2 min−1), electrodes maintain skin conformity and temperature parity with surrounding skin; EMG SNR comparable to gel due to increased skin moisture and low motion artifacts.

- ECG and EEG under sweating:

- ECG: Characteristic P–Q–R–S–T waves are identifiable at rest, during squatting, walking, and with local pressing after 30 min run (chest SR ~3.2 mg cm−2 min−1). Signal-to-noise ratio remains stable during movement.

- EEG: Forehead alpha rhythm (7–15 Hz; centered ~11.5 Hz) is reliably recorded during eyes-closed both before and after sweating (forehead SR ~2.6 mg cm−2 min−1), comparable to gel electrodes.

- Comfort and skin health:

- Porous 200 nm electrodes avoid sweat accumulation, preserving skin texture and preventing post-removal redness seen with gel and nonporous ultrathin electrodes; thermal measurements show no heat buildup over porous electrodes.

Discussion

The study demonstrates that a nano-thick, porous, stretchable dry electrode can simultaneously address motion artifacts and perspiration, the twin challenges that compromise EP monitoring during strenuous exercise. The ultrathin form factor ensures strong van der Waals adhesion and mechanical conformity, allowing the electrode to stretch with skin, minimizing relative motion at the interface. Engineered porosity provides high water vapor permeability to prevent sweat accumulation, maintaining both skin comfort and a stable electrical interface even during profuse sweating. The connector strategy further preserves system compliance while enabling robust electrical interfacing with acquisition hardware. Collectively, these features enable reliable multi-channel EMG acquisition at accelerations up to ~10 g and under high sweat rates, as well as stable ECG and microvolt-level EEG signals under similar conditions. The findings validate the hypothesis that combining ultrathin mechanics with tunable porosity yields dry electrodes capable of continuous, artifact-resistant electrophysiological monitoring in real-world exercise scenarios, advancing applications in healthcare monitoring, prosthetic control, and human–machine interfaces.

Conclusion

A porous nano-thick stretchable dry electrode system was developed using a rapid, equipment-free Marangoni-effect process to produce ultrathin SEBS films with tunable porosity, subsequently metallized with gold. The electrodes exhibit high stretchability (~120%), stable electrode–skin impedance under 0–14% skin strain, high water vapor permeability (~25.3 g h−1 m−2), and robust cyclic durability (1000 cycles at 30% strain). Integrated with a flexible CMD–ACF–FPCB connector, the system achieves continuous, multi-channel EP monitoring under strenuous motion (up to ~10 g acceleration) and heavy perspiration (sweat rates up to ~3.2 mg cm−2 min−1), delivering EMG, ECG, and EEG performance comparable to gel electrodes while improving comfort and skin health. Future work may focus on enhancing mechanical robustness against high localized pressures, mitigating modulus mismatch at the electrode–connector interface, and scaling array density and integration for broader clinical and wearable applications.

Limitations

- Mechanical robustness: The ultrathin porous electrode can be damaged under high localized pressing forces, indicating limited resistance to point loads.

- Modulus mismatch at the electrode–connector interface: Differences in Young’s modulus concentrate strain at the interface, especially under parallel stretching, which can impair signal acquisition stability.

- While adhesion and permeability are high, thicker variants (≥1 µm) show motion artifacts or detachment under sweat accumulation, limiting applicability of non-optimized thicknesses.

Related Publications

Explore these studies to deepen your understanding of the subject.