Medicine and Health

Solution-processable, soft, self-adhesive, and conductive polymer composites for soft electronics

P. Tan, H. Wang, et al.

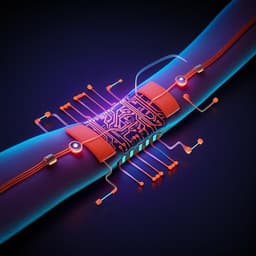

Soft electronics require reliable interfaces that can conform to irregular, dynamic biological tissues while maintaining stable electrical connections. Conventional PEDOT:PSS, despite good processability and biocompatibility, is rigid (Young’s modulus >500 MPa), weakly adhesive, and poorly stretchable (~5%), leading to mechanical mismatch with soft tissues (60–850 kPa) and unstable interfaces that degrade biosignal quality. Prior strategies (small-molecule doping, polymer blending, hydrogels, electrochemical adhesion methods) face trade-offs among softness, conductivity, plastic deformation, leakage concerns, and complicated processing. This study aims to develop a single, solution-processable conductive polymer composite that simultaneously exhibits low modulus, high stretchability, strong reversible adhesion, and high conductivity to serve as robust soft electrical interfaces for wearable and implantable bioelectronics.

Multiple materials have been explored for soft electrodes (hydrogels, carbon-based composites, liquid metal composites, metal composites, conducting polymers). PEDOT:PSS composites have been modified via ionic liquid doping, polymer blending, and hydrogel networks to increase conductivity or softness, but often at the expense of increased modulus (>10 MPa), limited stretchability (<200%), significant plastic deformation, potential dopant leakage, or reduced conductivity (<10 S/cm) in hydrogels. Adhesion enhancement methods such as electrogelation, electrografting, or added adhesion layers improve stability but require complex processing and typically yield non-reusable adhesion. Recent supramolecular and plasticizer approaches can soften PEDOT:PSS but still struggle to balance high conductivity with ultra-low modulus and reusability. The work addresses these gaps by introducing a supramolecular solvent and elastic network to achieve a more favorable balance of properties.

Material design and formulation: SACPs comprise three components: (1) a supramolecular solvent (SMS) of citric acid (H3Cit) and β-cyclodextrin (β-CD) at a 10:1 molar ratio; (2) an elastic polymer network formed by covalently crosslinking poly(vinyl alcohol) (PVA) with glutaraldehyde (GA); and (3) conductive PEDOT:PSS. SMS provides abundant hydrogen-bonding and electrostatic interactions with PSS and PEDOT, inhibiting PEDOT aggregation and enhancing chain mobility; PVA-GA networks impart reversible stretchability and reduce residual strain; SMS and charged groups enable strong interfacial adhesion. Preparation of SACP precursor and films: SMS and polymer solutions were prepared in water; SMS (β-CD:citric acid = 1:10 molar) and PVA solution with GA crosslinker were added to commercial PEDOT:PSS (Clevios PH1000, 1.1–1.3% solids) under vigorous agitation (~10 min), yielding a homogeneous aqueous ink (pH ~3–4). GA–PVA crosslinking was accelerated by citric acid. PEDOT:PSS mass ratio in final SACP was controlled by component masses (Equation (1) provided). Thick films were cast in PC molds and dried at 40 °C for 24 h after degassing. Thin films were spin-coated (typically 1000 rpm, 60 s) on cleaned, plasma-treated substrates and dried at 70 °C for 5 min. Microfluid molding used PDMS channels and vacuum-assisted injection, followed by drying at 40 °C for 24 h to yield 3D-deposited films. Transfer printing leveraged differential adhesion between PTFE and PI. Device fabrication: Transparent SACP electrodes were used to build AC electroluminescent (ACEL) devices via sequential spin-coating on PET: bottom SACP electrode (~7 μm), ZnS:Cu/PDMS emissive layer (~75 μm), top SACP electrode (~7 μm), PDMS encapsulation (~35 μm); total thickness <150 μm. Large-area SACP films were also made via Meyer rod coating. Mechanical testing: Uniaxial tensile tests (room temperature, RH 40–45%) on rectangular strips (length 30–40 mm, width 10 mm), speed 50 mm/min, with cyclic loading-unloading (e.g., to 200% strain for 100 cycles) and stepwise tests up to 500%. Residual strain and elastic resilience were evaluated; the effects of PEDOT:PSS ratio, GA concentration, and drying time were studied. Electrical characterization: Four-point probe (Keithley 2400) measured conductivity on films (length ~30–40 mm, width ~10 mm) with silver-paste contacts; thickness measured optically. Conductivity σ was calculated via σ = L/(Rwh). Strain-dependent resistance was measured during tensile loading (10 mm/min). Adhesion testing: 180° peel tests quantified interfacial adhesion (force per width, N/m) on cleaned substrates (Al, Cu, PET, PI, PEEK, PTFE, PDMS, etc.) at 50 mm/min; bonding time-dependence (0.5–120 min), storage stability (30 days at 30 °C, 40% RH), and cyclic reusability (≥100 cycles) were assessed. Lap-shear tests measured shear strength of SACP films (<50 μm) between substrates, varying film thickness (7–43 μm). Bioelectrode demonstrations: SACP films were adhered to skin to record electromyography (EMG) during hand gripping at varied forces (5–20 kg), compared against commercial Ag/AgCl electrodes. Reusability across ten uses and monitoring of activities (jumping, squatting, dumbbell lifting, push-ups) were demonstrated. Integrated system: An EMG-to-ACEL visualization system was built: SACP film electrodes captured EMG, a commercial EMG sensor and microcontroller performed signal conditioning, thresholding, and control, and a flexible SACP-electroded ACEL array displayed grip strength levels.

- Simultaneous softness, adhesion, and conductivity: SACP films achieved ultra-low Young’s modulus (as low as 56.1 ± 13 kPa), high stretchability (up to ~700%), low residual strain (<50% even after 500% strain), strong adhesion (peel forces up to ~400 N/m on PI at 0.9% PEDOT:PSS; robust adhesion across diverse substrates), high lap-shear strength (>1.2 MPa for film thickness ≥28 μm), and tunable conductivity from ~1 to 37 S/cm.

- Mechanical tuning by composition: Decreasing PEDOT:PSS mass ratio from 36.3% to 0.9% reduced Young’s modulus from MPa to tens of kPa and fracture stress from MPa to hundreds of kPa, while fracture strain increased (up to ~700% at <3.6% PEDOT:PSS). A formulation with 3.6% PEDOT:PSS yielded modulus ~401.9 kPa, fracture strain ~736%, fracture stress ~1.2 MPa, suitable for bioelectrodes.

- Elastic network and drying effects: Introducing PVA-GA networks reduced residual strain and improved elastic resilience; water content/drying time modulated mechanical properties via hydrogen-bond interactions.

- Electrical performance: Conductivity peaked at ~37 S/cm at ~36.3% PEDOT:PSS; uniform conductivity across film thicknesses from ~4 to 340 μm; relative resistance change <1 at 100% strain with stable cycling.

- Adhesion breadth and durability: Strong self-adhesion on many substrates (typical peel strengths: >150 N/m on PI, >120 N/m on PEEK, >100 N/m on Al/Cu/PET, >80 N/m on PTFE, >30 N/m on PDMS); rapid bonding (~30 s). Peel adhesion remained stable over 30 days storage; reusable over ≥100 adhesion cycles (after an initial ~25% drop by the second cycle). Lap-shear strength increased with film thickness (0.6 MPa at 7 μm to >1.2 MPa at ≥28 μm); significant adhesion anisotropy (shear >> peel).

- Solution processability and transparency: Coffee-ring-free, homogeneous aqueous ink (viscosity ~10^3–10^4 mPa·s) enabled microfluid molding, drop-casting + laser patterning, spin coating, Meyer rod coating, and transfer printing. Transparent films showed ~70–95% transmittance at 550 nm with sheet resistance ~1000 Ω/sq at ~90% transmittance and good bending/peeling durability.

- Device demonstrations: Thin, flexible ACEL devices (<150 μm) using SACP transparent electrodes operated under bending, folding, wrinkling, and after 24 h water immersion; on elastic substrates, emission varied predictably with strain. SACP films formed robust, low-impedance contacts and could be face-to-face laminated for durable electrical connections.

- Bioelectrode performance: SACP skin electrodes conformed to skin, maintained contact under deformation, and recorded EMG signals comparable to commercial Ag/AgCl electrodes. EMG amplitude increased monotonically with grip force (5, 10, 15, 20 kg); signals showed no significant attenuation over 10 repeated uses. Various activities (jump, squat, dumbbell lift, push-up) produced characteristic EMG waveforms.

- Integrated visualization system: An SACP-based system converted EMG from forearm muscles into real-time visual output on a flexible ACEL array, with pixel patterns corresponding to graded EMG thresholds linked to grip strength levels.

The study addresses core challenges in soft bioelectronics—mechanical mismatch, weak and non-reusable adhesion, and the conductivity–softness trade-off—by engineering a PEDOT:PSS composite with a supramolecular solvent and an elastic network. Hydrogen-bonding and electrostatic interactions from citric acid/β-cyclodextrin disrupt PEDOT aggregation and promote chain mobility, reducing modulus while maintaining conductivity. The PVA–GA network imparts reversible elasticity and suppresses plastic deformation, yielding low residual strain. Abundant hydroxyl and charged groups enable strong, rapid, and reusable adhesion on a wide range of substrates, lowering interfacial impedance and enhancing device durability. Compared to ionic liquid-doped systems (high conductivity but high modulus and plasticity) and hydrogels (soft but lower conductivity and large residual strain), SACPs achieve a favorable balance: conductivity up to 37 S/cm combined with tissue-like modulus (down to ~56 kPa), high extensibility, and robust, reusable adhesion. These properties translate into reliable, solution-processed electrodes for transparent, flexible ACEL devices and skin-mounted EMG electrodes that capture high-quality biosignals comparable to commercial standards. The integrated EMG-to-ACEL system demonstrates direct, real-time visualization of muscle activity, highlighting SACP’s potential for comfortable, wearable bioelectronic interfaces and interactive displays.

This work introduces a solution-processable, self-adhesive, and conductive PEDOT:PSS-based composite (SACP) that unifies tissue-like softness, high stretchability, strong and reusable adhesion, and appreciable conductivity. The materials framework—supramolecular solvent doping plus an elastic PVA–GA network—enables scalable fabrication of films and patterns via standard wet processes and supports robust electrical interfaces for soft devices. Demonstrations include transparent, ultrathin ACEL devices operating under extreme deformation and skin-conformal EMG electrodes with performance on par with commercial electrodes, culminating in an integrated system that visualizes EMG-derived muscle activity in real time. Future directions may include optimizing the conductivity–softness balance for specific applications, long-term biocompatibility and skin-wear studies, integration with additional biosignal modalities, large-area/complex circuit printing, and exploring encapsulation strategies for harsh environments or implantable use.

- Conductivity–softness trade-off persists: maximum conductivity (~37 S/cm) occurs at higher PEDOT:PSS content with higher modulus; softer formulations (e.g., 3.6% PEDOT:PSS) exhibit lower conductivity (~3.79 S/cm).

- Adhesion anisotropy: lap-shear strength (>1.2 MPa) substantially exceeds peel strength (typically tens to hundreds of N/m), which may influence failure modes under different loading conditions.

- Reuse effect: peel adhesion shows an initial ~25% decrease on the second adhesion cycle before stabilizing over ≥100 cycles.

- Environmental sensitivity: mechanical properties vary with water content/drying time due to hydrogen-bond dynamics in the supramolecular system.

- The article does not report long-term in vivo performance, extended skin irritation/biocompatibility studies, or very long-duration wear; implantable use remains to be evaluated.

Related Publications

Explore these studies to deepen your understanding of the subject.