Engineering and Technology

Soft, stretchable thermal protective substrates for wearable electronics

S. Nie, M. Cai, et al.

The study addresses the challenge of preventing undesired heat transfer from wearable electronics to skin, which can cause discomfort and thermal damage. Conventional soft polymer substrates like PDMS and Ecoflex have low thermal insulation, and prior approaches using low thermal conductivity fillers or phase change materials face issues such as rigidity or leakage, limiting suitability for skin-mounted devices. Recent designs that direct heat flow can improve insulation but often compromise flexibility and stretchability. The research aims to develop a soft, stretchable thermal protective substrate that provides effective thermal protection while maintaining mechanical compliance and stretchability to preserve a reliable, conformal skin-device interface.

Prior work in wearable electronics has integrated functional components onto soft polymer substrates for health monitoring, wound management, and drug delivery. Thermal management approaches include adding low-thermal-conductivity fillers (e.g., hollow microspheres, aerogels) and embedding phase change materials (PCMs) such as paraffin wax or polyethylene glycol to absorb latent heat at constant transition temperatures. However, composites with solid fillers can increase rigidity, while PCMs can suffer from liquid leakage, both unsuitable for wearable applications. Orthotropic substrates and functional soft composites that control heat flow show promise but reduce flexibility and stretchability. Candidate PCMs with high latent heat (e.g., palmitic acid, myristic acid, pentaglycerine) often have phase change temperatures above 55 °C, risking tissue damage. For wearable thermal protection, the PCM transition temperature should be above core body temperature (~37 °C) and below discomfort thresholds (~43 °C). This work leverages n-eicosane PCMs with transition ~37 °C encapsulated in melamine-formaldehyde shells to prevent leakage and to chemically inhibit PDMS cross-linking, targeting a balance of insulation, softness, and stretchability.

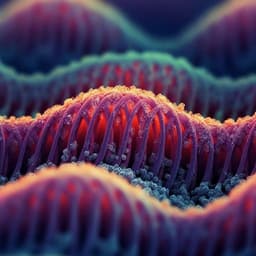

Materials and fabrication: PDMS (Sylgard 184) base and curing agent were mixed at 10:1 mass ratio. Heat-absorbing microspheres (GreenTech LF) consisting of n-eicosane (phase change ~37 °C) encapsulated in melamine-formaldehyde resin shells (diameter ~30 μm) were mixed into liquid PDMS at mass ratios from 0 to 80%. The mixture was poured into molds, degassed for 30 min, then cured at 85 °C for 3 h, 99 °C for 3 h, and 115 °C for 12 h. Spin coating can produce thin films for encapsulation or additional layers. Patterns (e.g., kirigami) can be achieved via screen printing. The encapsulation shell reacts with the platinum catalyst to inhibit PDMS cross-linking, yielding a softer, more adhesive composite.

Mechanical testing: TPS samples with varying microsphere mass ratios (0–80%) were tested for elastic modulus across temperatures (20, 50, 100 °C) and maximum tensile strain at 25 °C and 100 °C. Fatigue testing used a 50% strain at 3 Hz for 5000 cycles, recording stress response.

Thermal characterization: Using a high-temperature synchronous thermal analyzer (NETZSCH DSC 214), thermal conductivity was measured before (25 °C) and after (50 °C) phase change as a function of microsphere mass ratio. Specific heat capacity versus temperature was measured to identify endothermic peaks and quantify latent heat as a function of mass ratio. Density was measured versus mass ratio.

Device-level thermal tests: A wearable heater (10 mm diameter, 20 μm thickness) was mounted on TPS disks (20 mm diameter) of defined thickness (e.g., 1.4 mm). Ambient temperature was 29 °C. Infrared thermal imaging measured the maximum temperature on the bottom surface of the substrate (skin side surrogate). Tests varied mass ratio (0–80%), thickness (0.8–1.4 mm), heating power (140, 210, 270 mW), heating duration (75–300 s), and applied tensile strain (0, 30, 50, 80%). Repetitive heating tests placed samples on hot plates (70–80 °C) to assess stability over cycles.

Finite element analysis: A 3D thermal model in COMSOL modeled the heater as a surface heat source. Free surfaces used natural convection (coefficient 14 W m⁻² K⁻¹) with ambient at 29 °C. Measured thermal properties (conductivity, density, specific heat) were input. TPS phase change temperature set to 37 °C with latent heat from measurements. Mesh sizes 0.0315–0.735 mm (~25,000 elements), refined near heat source. Convergence verified (<0.1% change vs finer mesh).

In vivo experiments: ICR mice were depilated and randomized into three groups (n=5): NC (no operation), PDMS substrate, and TPS substrate (thickness 1.3 mm). A heater operated for 40 s at 445 mW, then off for 140 s. Infrared thermal imaging recorded temperatures immediately after heating (40 s) and at 180 s. Post-experiment, damaged skin areas were photographed and quantified; skin samples underwent H&E staining to assess morphology and epidermal thickness. Protocol approved by Zhejiang Center of Laboratory Animals (Approval No. ZICLA-IACUC-20020030).

- TPS design: PDMS matrix embedded with melamine-formaldehyde encapsulated n-eicosane microspheres yields a soft, stretchable, adhesive thermal protective substrate. Encapsulation both prevents PCM leakage and inhibits PDMS cross-linking for softness.

- Mechanical properties: Elastic modulus decreases by ~98% from 1.56 MPa (0% microspheres) to 0.023 MPa (80% microspheres). TPS sustains complex deformations over 150% strain and shows stable cyclic behavior under 50% strain at 3 Hz for 5000 cycles with negligible stress degradation. Maximum tensile strain increases modestly with mass ratio: at 25 °C from 194.3% (0%) to 226.1% (80%); at 100 °C from 157.6% to 182.1%.

- Density: Approximately constant at ~970 g cm⁻³ across mass ratios.

- Thermal conductivity: At 25 °C (before PCM phase change), increases from 0.177 to 0.218 W m⁻¹ K⁻¹ as mass ratio increases 0→80%. At 50 °C (after phase change), decreases slightly from 0.177 to 0.163 W m⁻¹ K⁻¹ over 0→80%.

- Specific heat and latent heat: PDMS cp ~1.35 J g⁻¹ K⁻¹ without phase transition. TPS shows an endothermic peak near 37 °C; peak magnitude and latent heat increase with microsphere mass ratio, with latent heat scaling approximately linearly with loading.

- Thermal insulation (bench tests): With a wearable heater (140 mW) and 1.4 mm substrate over 75 s, peak bottom-surface temperatures: PDMS 51 °C; TPS 20% 47 °C; 40% 41 °C; 80% 33 °C. Corresponding peak temperature increase reductions vs PDMS: 18%, 45%, and 82%. Over longer heating (300 s), TPS exhibits two-stage response: slow rise during PCM melting then PDMS-like behavior post-melting; steady-state max temperature decreases slightly with higher loading (e.g., 59.5 °C at 0% to 55.3 °C at 80%).

- Thickness and power effects: For 80% TPS, greater thickness (e.g., 1.4 mm) ensures sufficient PCM to cover heating duration, minimizing peak temperature; thinner substrates (0.8–1.0 mm) exhaust PCM earlier, increasing peak temperature. Higher heating power (140→270 mW) increases peak temperatures. External tensile strain up to 80% shows negligible effect on peak temperature.

- Hot plate demonstration: On an 80 °C plate for 10 s, 1 mm TPS (80% loading) top surface max ~53 °C versus PDMS ~68 °C; TPS remains mostly below 50 °C. TPS maintains stable performance over at least 50 heating cycles (70 °C plate, 1.3 mm thickness).

- In vivo (mice, 1.3 mm substrates, 445 mW, 40 s): Skin surface max temperature: PDMS 48.0 °C vs TPS 40.8 °C. At 180 s (post-cooling), TPS 34.8 °C vs PDMS 39.0 °C. Tissue outcomes: visible blisters in all PDMS mice; slight blisters in TPS group. Damaged skin area: PDMS 0.739 cm² vs TPS 0.057 cm². H&E staining: PDMS shows loss of cutaneous appendages and epidermal detachment; TPS maintains morphology. Epidermal thickness: NC 22.54 μm; PDMS 9.36 μm; TPS 19.05 μm.

The TPS effectively addresses the core problem of heat transfer from wearable devices to skin by leveraging latent heat absorption from encapsulated PCMs while preserving mechanical compliance through cross-linking inhibition. The two-stage thermal response demonstrates that, during PCM melting, heat is absorbed, significantly suppressing peak skin-side temperatures, after which behavior resembles PDMS once PCM is exhausted. Optimization of TPS thickness to match heating power and duration maximizes protection by ensuring continuous phase change over the operating window. Mechanical results confirm that high filler loadings do not compromise, and even modestly enhance, stretchability at break due to reduced cross-link density, enabling conformal skin contact and reliable interface. Thermal characterization guides design: although thermal conductivity may increase pre-transition and decrease post-transition, the dominant latent heat effect governs protection. In vivo results corroborate bench and simulation findings, demonstrating substantial reduction in peak skin temperature and tissue damage, validating TPS as a practical solution for thermal management in wearable electronics.

This work introduces a soft, stretchable thermal protective substrate for wearable electronics, formed by embedding melamine-formaldehyde encapsulated n-eicosane microspheres into PDMS. The design achieves a rare combination of high thermal insulation, mechanical compliance, and large stretchability. Experiments and simulations show up to 82% reduction in peak skin-side temperature increase under optimized conditions, stable cyclic performance, and minimal sensitivity to stretch. In vivo mouse studies demonstrate markedly reduced skin heating and tissue damage versus PDMS. Future work could optimize optical properties to achieve transparency, explore alternative elastomer matrices (e.g., thermoplastic elastomers) to increase filler loading, integrate microfabrication-compatible processes, and tailor PCM transition temperatures and latent heats for different use cases and thermal loads.

- Optical appearance: The high loading of white heat-absorbing microspheres renders the substrate milky white, limiting applications requiring optical transparency.

- Microfabrication compatibility: The TPS is not directly compatible with conventional microfabrication processes, although patterning by screen printing is possible.

- Thermal operating window: Protection depends on matching PCM content and thickness to device power and operating duration; once PCM is fully melted, insulation benefit diminishes.

- Material system: PDMS cross-linking inhibition facilitates softness but may constrain maximum filler loading compared to thermoplastic elastomers, suggesting room to optimize matrix choice for higher PCM loading.

Related Publications

Explore these studies to deepen your understanding of the subject.