Engineering and Technology

Single-step fabrication of liquid gallium nanoparticles via capillary interaction for dynamic structural colours

R. R. Sahu, A. S. Ramasamy, et al.

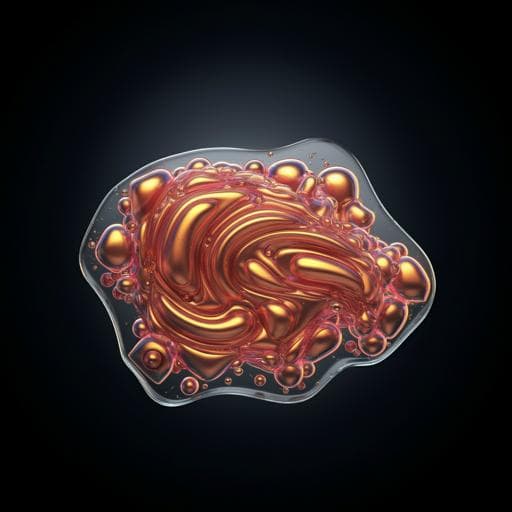

Structural colour with mechanochromic responsiveness is attractive for visual communication, sensing and display technologies, but most existing fabrication routes are multi-step, require rigid substrates, or rely on top-down lithography or bottom-up self-assembly that are difficult to scale economically. Polydimethylsiloxane (PDMS) is a popular soft, transparent, biocompatible substrate, yet integrating structural colour into PDMS typically involves complex chemical procedures. Gallium (Ga), a liquid metal with plasmonic response comparable to Au and Ag, promises flexible and reconfigurable devices; however, nanostructuring Ga below 100 nm is challenging due to its high surface tension, and reported syntheses often produce colloidal nanoparticles in liquids, not solid-supported architectures. The study addresses the need for a scalable, single-step method to produce nanoscale Ga features directly in soft elastomers with dynamically tunable colour. The authors propose thermal evaporation of Ga onto PDMS containing uncrosslinked oligomers, leveraging capillary interactions to form embedded Ga nanodroplets whose plasmonic coupling enables tunable structural colour.

Prior approaches to structural colour include spin coating, 3D printing, lithography, rubbing, nanoimprinting, and photosensitive polymers with periodic refractive-index modulation. Many require rigid substrates and are not mechanoresponsive; pattern transfer and laser printing can impart responsiveness but add complexity and reduce scalability. Bottom-up self-assembly offers periodic nanostructures but entails multiple processing steps and fidelity challenges for cost-effective, large-area fabrication. For Ga-based plasmonics, the high surface tension of Ga at room temperature hampers sub-100 nm patterning needed for visible plasmonics; reported nanoparticle syntheses often rely on chemical methods yielding dispersions in liquids rather than solid-supported, device-ready films. These gaps motivate a single-step, scalable process that controls nanoscale morphology on elastomers while enabling mechanochromism.

Fabrication: PDMS substrates (Sylgard 184) are prepared by mixing PDMS base with curing agent in weight ratios denoted PDMS X (X:1 base:curing agent). Ratios used include PDMS 5, 10, 15, and 20. Mixtures are stirred, degassed, poured into polystyrene Petri dishes, and thermally cured at 80 °C for 2 h, leaving uncrosslinked oligomeric PDMS chains within the crosslinked matrix. Liquid gallium (99.999%) is thermally evaporated (HHV thermal evaporator) onto the substrates; thickness and substrate temperature are monitored in situ. Deposition parameters (substrate temperature, nominal thickness) and PDMS ratio are varied to tune colour and morphology. For control experiments, oligomers are removed from PDMS by toluene extraction (multiple solvent exchanges), followed by ethanol rinse and vacuum drying, prior to Ga deposition. Post-fabrication oligomer extraction verifies the role of oligomers by erasing structural colour. For protection, a PDMS superstrate (same ratio as substrate) is cast on top and cured at 80 °C for 2 h. Characterization: Top-view and cross-section morphologies are obtained by SEM (Zeiss Gemini ULTRA 500; samples sputtered with 10 nm Au), focused ion beam (Thermo Fisher Scios Dual Beam) for TEM lamella, and STEM-HAADF imaging (ThermoFisher Titan Themis, 300 kV) with EDAX elemental mapping to resolve Ga, Si, and O distributions. Interfacial tensions are measured by pendant-drop goniometry (Dataphysics OCA 25). Optical reflectivity at normal incidence is measured using an Ocean Optics FLAME UV–vis spectrophotometer; spectra are smoothed and converted in real time to CIE x, y and hue using Python (numpy, matplotlib, seabreeze). Mechanical testing uses a custom Arduino-controlled stepper-motor stretcher applying linear and periodic strains to 5 cm × 1 cm samples; strain up to at least 60% is applied. Modelling: The authors develop coupled equations for substrate oligomer availability (S), Ga droplet growth (G), and engulfing (E), solved iteratively per layer:

- df/dt = −ks (f − 2πR² w (1 + cosθ)) (2πR sinθ)

- dR/dt = kp (1 − cosθ)

- dθ/dt = −ke (f − 2πR² w (1 + cosθ)) where f is oligomer volume in a representative substrate region, R the Ga droplet radius, θ the engulfing angle, w the oligomer shell thickness, and ks, kp, ke proportionality constants determined by fitting for given substrates and deposition parameters. Spreading parameter S = γGa − (γoligomers−Ga + γoligomers) is evaluated with measured interfacial tensions (γGa ≈ 650 mN m−1, γoligomers ≈ 20 mN m−1, γoligomers−Ga ≈ 590 mN m−1), indicating positive S and oligomer cloaking. Electromagnetic simulations: FDTD (Lumerical) models use measured size distributions and random in-plane placements of Ga droplets in layered structures within a 1 µm × 1 µm periodic unit cell. PDMS refractive index is 1.4; Ga optical constants are wavelength-dependent complex n,k. Perfectly matched layer boundaries are used where appropriate; total-field scattered-field sources and frequency-domain monitors extract back-scattered power and field profiles. Dimer simulations probe gap-plasmon resonances under polarization aligned with the interparticle gap. Stability tests: Encapsulated samples are tested for washability (soap solution, 12 h), solvent exposure (toluene 6 h, ethanol 3 h; swelling and recovery), thermal endurance (180 °C for 12 h with real-time spectral monitoring), and performance under pre-stretch.

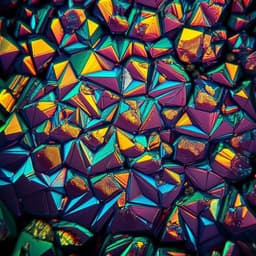

• Single-step thermal evaporation of Ga onto PDMS containing uncrosslinked oligomers yields embedded, multilayer Ga nanodroplet ensembles with tunable structural colours across a wide CIE gamut, fabricated over large areas (~30 cm²) and on flexible substrates. • Morphology control via PDMS ratio (oligomer content), substrate temperature, and deposited thickness: on rigid Si and glass, droplets are polydisperse (~70 nm on Si; ~40 nm on glass), while on PDMS they are narrowly dispersed with mean radius ~20 nm (σ ≈ 10 nm). Increasing PDMS ratio (softer, higher oligomer content) reduces mean droplet size, increases the number of layers, and yields radii that decrease with depth due to growth time and oligomer availability. • Cross-section SEM/HAADF and EDAX maps show multiple buried layers of Ga nanodroplets cloaked by PDMS oligomers, which occupy the inter-droplet gaps and prevent coalescence. Post-fabrication toluene extraction of oligomers removes the colour and restores PDMS transparency, supporting the fluidic oligomer cloaking mechanism. • Interfacial tension measurements give γGa ≈ 650 mN m−1, γoligomers ≈ 20 mN m−1, γoligomers−Ga ≈ 590 mN m−1, yielding a positive spreading parameter (reported S ≈ 40 mN m−2) that drives oligomer cloaking of Ga droplets. • The S–G–E mathematical model reproduces experimental trends: smaller droplet radii and more layers at higher PDMS ratios; radii decreasing with depth; and layer-by-layer engulfing timescales (first layer fastest, subsequent layers progressively slower and limited by oligomer volume). • Optical response: With increasing PDMS ratio (higher oligomer content), reflectivity spectra exhibit a red shift, contrary to the expectation from smaller droplet sizes; simulations and field maps attribute this to increased thickness and coupling of multiple droplet layers, so the collective multilayer gap plasmon interactions dominate. The strongest reflectivity peak corresponds to wavelengths that excite inter- and intra-layer gap plasmons across all layers. • Mechanochromism: Uniaxial stretching increases inter-droplet gaps along the stretch direction, producing a blue shift in reflectivity (measured shift ~3.68 nm per mm length change). Hue changes from ~6° to ~65°, and chromaticity coordinates move accordingly. Periodic strain tests show repeatable, reversible spectral shifts over at least 1,000 cycles; overall mechanochromic reproducibility is reported for ~80,000 cycles. • Gap-plasmon mechanism is validated by dimer simulations: polarization along the gap produces blue-shifting resonances with increasing gap, while perpendicular polarization shows negligible shift. UV reflectivity features are attributed to Mie scattering by individual droplets. • A thin native Ga2O3 shell (~2–3 nm) forms post-exposure; simulations and experiments show minimal impact on visible optical trends, while improving structural stability. • Temperature during deposition affects condensation/growth (higher temperature suppresses condensation and reduces sizes), but fabricated samples remain robust to wide temperature variations post-fabrication. Encapsulation enhances durability under washing, solvents (with reversible swelling), high temperature (180 °C, 12 h), static stretch, and handling. • Demonstrated applications include reflective displays, curvature sensing, point-stress mapping with spatial hue analysis, body motion and finger-bend monitoring, smart bandages, and local strain mapping under twists/knots.

The work demonstrates that capillarity-driven interactions between liquid Ga and fluidic PDMS oligomers dominate nanoscale morphology formation in soft elastomers, outweighing substrate elasticity in determining optical functionality. By exploiting a positive spreading parameter, the process yields cloaked Ga nanodroplets that self-organize into multiple embedded layers, enabling strong gap-plasmon coupling both within and between layers. This architecture produces vivid structural colours whose spectra can be deterministically tuned by oligomer content (via PDMS ratio) and dynamically modulated by mechanical deformation, addressing the central challenge of scalable mechanochromic structural colour on flexible substrates. The coupled S–G–E model provides a predictive framework linking deposition conditions and substrate composition to droplet sizes, layer counts, and formation dynamics, allowing rational process design. The optical-mechanical coupling—blue-shifting under tensile strain due to increased interparticle gaps—enables reliable chromatic sensing of local and global strain, as validated by repeatable cycling and application prototypes. The minimal impact of a native oxide shell and the demonstrated robustness with PDMS encapsulation further enhance practical relevance for wearable and soft robotic systems.

This study introduces a scalable, single-step route to produce mechanochromic structural colours by thermally evaporating Ga onto PDMS containing uncrosslinked oligomers. Capillarity-induced oligomer cloaking generates embedded multilayer Ga nanodroplets with controlled size distributions and interlayer coupling, yielding tunable reflective colours that respond reversibly to strain. A compact physics-based S–G–E model connects oligomer availability, droplet growth, and engulfing to the resulting layered morphologies and optical response, guiding process optimization. The platform enables large-area chromogenic patterns, robust operation with encapsulation, and practical sensing demonstrations for curvature, point stress, and motion monitoring. Potential future research directions include: extending the approach to other liquid metals or alloys and alternative elastomers; engineering oligomer content and interfacial energies to further expand colour gamut and sensitivity; patterned or spatially graded oligomer distributions for pixelated displays; quantitative calibration frameworks linking hue/CIE shifts to strain or pressure for metrology; and long-term environmental and fatigue studies under diverse wearable use conditions.

The colour formation critically depends on the presence of uncrosslinked PDMS oligomers; removing oligomers before deposition yields only a monolayer with limited colour variation, and extracting oligomers post-fabrication erases the structural colour. The S–G–E model uses fitted proportionality constants specific to substrate composition and deposition conditions, which may limit direct generalizability without calibration. Deposition temperature must be controlled to maintain consistent condensation and growth dynamics. On rigid substrates, the method produces polydisperse droplets and less tunable colours. While repeatability is shown for 1,000-cycle periodic strain tests and overall reproducibility is reported up to ~80,000 cycles, comprehensive lifetime and environmental durability data across all use scenarios remain to be fully established without encapsulation.

Related Publications

Explore these studies to deepen your understanding of the subject.