Engineering and Technology

Self-growing photonic composites with programmable colors and mechanical properties

J. Xue, X. Yin, et al.

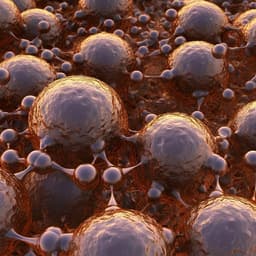

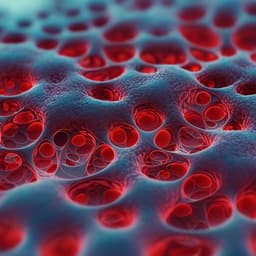

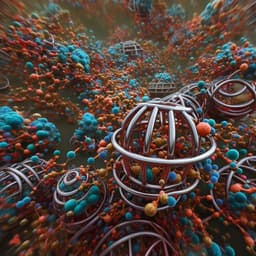

This innovative research, conducted by Juan Xue, Xuewu Yin, Lulu Xue, Chenglin Zhang, Shihua Dong, Li Yang, Yuanlai Fang, Yong Li, Ling Li, and Jiaxi Cui, explores a groundbreaking approach to creating advanced structural color materials inspired by the remarkable color-changing abilities of peacock feathers. The self-growing photonic composite system enables on-demand tuning of colors and properties, introducing flexibility, toughness, and self-healing features into the materials.

Playback language: English

Related Publications

Explore these studies to deepen your understanding of the subject.