Engineering and Technology

Sea urchin-like microstructure pressure sensors with an ultra-broad range and high sensitivity

X. Wang, L. Tao, et al.

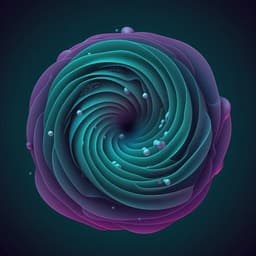

The study addresses a central challenge in flexible pressure sensing: simultaneously achieving high sensitivity and a broad working pressure range. Conventional piezoresistive, capacitive, piezoelectric, and triboelectric sensors often trade off sensitivity for range. Micro/nanostructured geometries (interlocked, hollow-sphere, micropyramids, porous) can raise sensitivity, but sea urchin-like (tapered spine) architectures—while enhancing transduction and mechanical robustness—typically exhibit high sensitivity only at very low pressures. The authors hypothesize that coupling a sea-urchin-like metal oxide with conductive carbon and forming semiconductor heterostructures can synergistically lower initial current, enhance contact-dependent current modulation, and extend the pressure range. They design a ternary Fe₂O₃/C@SnO₂ composite combining Fe₂O₃/C, Fe₂O₃/SnO₂ heterojunctions, and SnO₂@C to achieve an ultra-broad range with high sensitivity for wearable and health monitoring applications.

The paper situates its work in the context of flexible pressure sensors used in wearables, e-skins, and HMIs. Prior art spans capacitive, piezoresistive, piezoelectric, and triboelectric mechanisms. Piezoresistive sensors offer low power, simple readout, and high sensitivity and have leveraged various microstructures to boost performance. Sea-urchin-like geometries have shown promise for sensitivity and mechanical resilience, e.g., ZnO microparticles achieving ~121 kPa⁻¹ over 0–10 Pa, sea-urchin-shaped metal nanoparticles yielding ~2.46 kPa⁻¹ over 0–1 kPa, and urchin-like hollow carbon spheres reaching 260.3 kPa⁻¹ at 1 Pa, but these operate effectively only in narrow, low-pressure regimes. The authors note that semiconductor/conductor interface piezoresistive effects and semiconductor heterojunctions can enhance charge transport via depletion regions and band bending, as widely used in LEDs, photodetectors, and solar cells. This motivates integrating metal oxide semiconductor/C composites with heterostructures to overcome the typical sensitivity–range trade-off.

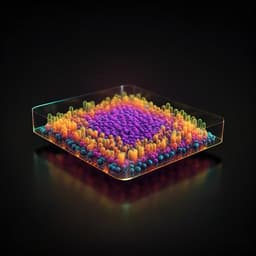

Materials synthesis and device fabrication: 1) Fe₂O₃ synthesis: Fe₂O₃ with sea-urchin-like morphology was prepared hydrothermally by dissolving 0.405 g FeCl₃·6H₂O and 0.205 g Na₂SO₄ in 30 mL distilled water, stirring 10 min, then heating at 120 °C for 6 h in a Teflon-lined autoclave. The product was cooled, filtered, dried, and annealed at 400 °C for 3 h in air. 2) Fe₂O₃/C composites: Prepared similarly by introducing acetylene black carbon at various mass ratios; one portion of carbon coated Fe₂O₃ particles while another embedded within Fe₂O₃ needle gaps to form Fe₂O₃/C. 3) Fe₂O₃/C@SnO₂ composites: Fe₂O₃/C (0.145 g), Na₂SnO₃ (0.145 g, 0.036 g, or 0.290 g per target loading), and urea (1.16 g, 0.290 g, or 2.320 g) were dissolved in ethanol/H₂O (V_ethanol:V_H₂O = 2:3), stirred 15 min, then reacted at 180 °C for 6 h hydrothermally. After washing (water, ethanol) and drying at 60 °C for 12 h, composites were obtained. SnO₂ nanoparticles partly adhere to Fe₂O₃ needles, forming Fe₂O₃/SnO₂ n–n heterojunctions, and partly disperse within the carbon layer forming SnO₂@C. 4) Fe₂O₃/C@Sb₂O₃ composites: 0.34 g Fe₂O₃/C and 0.34 g SbCl₃ in 40 mL ethanol, stirred 30 min, hydrothermally treated at 140 °C for 12 h, then cooled, filtered, dried, and annealed at 400 °C for 3 h. Conductive sponge sensor assembly: Melamine sponge (19×19×4 mm³) was washed with ethanol and dried at 45 °C. A slurry of active material (Fe₂O₃/C@SnO₂, or controls: SnO₂@C, Fe₂O₃/C, Fe₂O₃, SnO₂, or C) and PVDF binder in NMP (10:1 by weight) was prepared. The sponge was dip-coated (immersed until saturated) and vacuum-dried at 45 °C. Electrodes were formed by fixing a copper wire to a PI film coated with laser-induced graphene (LIG) using silver paste; PI-LIG served as the device electrode, and copper tape flattened the PI film. Structural and chemical characterization: XRD (PANalytical X'Pert Powder) to confirm phases (Fe₂O₃ JCPDS 33-0664; SnO₂ JCPDS 41-1445; carbon (002) broad peak). Morphology and distribution examined by SEM (Quattro S), TEM (Talos F200S), HRTEM, HAADF-STEM, and EDX elemental mapping; HRTEM verified (104) Fe₂O₃/(110) SnO₂ heterojunctions. XPS (ESCALAB250Xi) confirmed Fe 2p, C 1s, O 1s, and Sn 3d states; Sn 3d₅/₂ ~484.9 eV and 3d₃/₂ ~493.3 eV with 8.4 eV splitting indicative of SnO₂. Electrical and mechanical testing: Piezoresistive measurements used a universal testing machine (ETM-5038) synchronized with a digital sourcemeter (Keithley 2450) at 0.1 V. Sensitivity S = (ΔI/I_unloading)/Δp, with ΔI = I_loading − I_unloading. Response time measured by compressing 0.02 mm at 500 mm/min and recording with a multimeter (Keithley DAQ6510). Stability assessed under repeated loading/unloading (over 3500 cycles at 110 kPa). Environmental and geometric robustness were tested across RH = 73%, 85%, 95%, and different sponge areas and thicknesses. Demonstrations: Low-pressure detection placed a 4.2 g glass slide atop the sensor, then added a paper (~0.52 Pa; m=0.0107 g; 1×2 cm²) and a rice grain (m=0.0116 g). High-pressure resolution was probed by applying baseline pressures (1.5, 10, 50 kPa) and adding three coins (~3.19 g each; ~86 Pa increments). Extreme load tests placed the sensor under a car tire (vehicle mass 1670 kg), then monitored current changes when a 4 kg mass was placed on the driver seat and when a 73 kg person entered/exited. Additional high-pressure sensitivity was probed around P₀ = 210 kPa by adding 2.8 and 25 kPa.

- The ternary Fe₂O₃/C@SnO₂ (3:1:4) pressure sensor achieved multi-regime sensitivities: S₁ ≈ 680 kPa⁻¹ (0–10 kPa), S₂ ≈ 98 kPa⁻¹ (10–50 kPa), S₃ ≈ 35 kPa⁻¹ (50–150 kPa), outperforming single-component and binary controls (Fe₂O₃ alone ~3, 3, 2 kPa⁻¹; SnO₂ alone ~1, 1, 0.6 kPa⁻¹; Fe₂O₃/SnO₂ (3:4) ~8.5, 8.5, 8 kPa⁻¹; Fe₂O₃/C@Fe₂O₃ (3:1:4) ~70, 9, 2 kPa⁻¹ for the same pressure ranges). - Fast dynamics: response time ~10 ms and recovery ~22 ms under 0.02 mm compression at 500 mm/min. - Broad range and stability: clear, monotonic current increase across 3, 8, 14, 22 kPa; reproducible over >3500 cycles at 110 kPa without signal drift; microstructure largely retained with minimal needle detachment. - Environmental and geometric robustness: insensitive to RH (73%, 85%, 95%) and to sponge area/thickness variations. - High pressure resolution: resolved ~86 Pa increments (coins) superimposed on baselines of 1.5, 10, and 50 kPa with stable steps; maintained sensitivity at high preload (P₀ ≈ 210 kPa) with additional 2.8 and 25 kPa. - Low-limit detection: detected a paper load ~0.52 Pa (0.0107 g over 1×2 cm²) and a single rice grain (0.0116 g) placed via a stabilizing glass slide (4.2 g). - Real-world demonstrations: detected wrist pulse (~73 bpm), speech (words one, two, three), chewing/occlusion, fist clenching (muscle contractions), graded finger bends (six motions with distinct signals), and walking gait; detected macroscopic loads in a car test (4 kg mass on seat; 73 kg person entering/exiting), capturing motion-induced pressure fluctuations. - Structure–performance relationships: optimal Fe₂O₃:C mass ratio was 3:1 for Fe₂O₃/C, giving higher sensitivity than 4:1, 2:1, 1:1, 1:2, or pure carbon; for ternary composites, Fe₂O₃/C@SnO₂ (3:1:4) outperformed (3:1:1) and (3:1:8), where underloading reduced conductivity improvement and overloading led to SnO₂ aggregation and non-uniform distribution. - Universality: analogous ternary Fe₂O₃/C@Sb₂O₃ (3:1:4) showed high sensitivities S₁ ≈ 303 kPa⁻¹ (0–10 kPa), S₂ ≈ 180 kPa⁻¹ (10–50 kPa), S₃ ≈ 13 kPa⁻¹ (50–150 kPa), supporting the generality of the ternary strategy.

The results validate the central hypothesis that combining a sea-urchin-like microstructure with conductive carbon and a semiconductor heterojunction can reconcile high sensitivity with an ultra-broad pressure range. The Fe₂O₃ sea-urchin morphology enhances stress concentration and contact evolution while protecting needles from mechanical breakage, facilitating reliable signal transduction. Carbon incorporation (Fe₂O₃/C and SnO₂@C) reduces baseline conductivity of pure oxides to an optimal level and increases conductive pathways, enabling large relative current modulation upon pressure-induced contact changes. The Fe₂O₃/SnO₂ n–n heterojunctions formed by high-temperature equilibration promote band alignment and electron transfer (from Fe₂O₃ to SnO₂), lowering interfacial resistance and aiding charge transport. Together, the three synergistic structures (Fe₂O₃/C, Fe₂O₃/SnO₂, SnO₂@C) expand the effective sensing range while preserving high sensitivity, surpassing prior sea-urchin-based sensors that operated mainly at very low pressures. Robust performance under humidity variations and geometric changes, rapid response, cycle durability at high pressures, and diverse wearable demonstrations underscore the sensor's applicability to health monitoring and human–machine interfaces.

This work introduces a simple, eco-friendly hydrothermal route to a ternary Fe₂O₃/C@SnO₂ nanocomposite with sea-urchin-like microstructure and demonstrates a piezoresistive pressure sensor exhibiting simultaneously high sensitivity (up to ~680 kPa⁻¹), fast response (10 ms), and an ultra-broad operating range (to 150 kPa) with strong durability (>3500 cycles at 110 kPa). The performance stems from the synergy of Fe₂O₃/C, Fe₂O₃/SnO₂ heterojunctions, and SnO₂@C, which together optimize interfacial transport and contact mechanics. Demonstrations across physiological signals and daily motions highlight practical potential in wearable electronics and health monitoring. Future research could optimize composition and microstructure for even broader ranges and lower detection limits, integrate sensor arrays for spatial pressure mapping, explore biocompatible/skin-conformal packaging, assess long-term drift and environmental robustness over extended periods, and generalize the ternary strategy to other oxide/carbon systems.

The paper does not explicitly detail limitations. Empirically, validated sensitivity regimes are reported up to 150 kPa (with additional tests around a 210 kPa preload), and durability was demonstrated over ~3500 cycles at 110 kPa; longer-term aging/drift and performance beyond these ranges are not reported. The device relies on a melamine sponge substrate, which may influence hysteresis (noted recovery time lag) and could affect performance under different mechanical loading histories. Biocompatibility and large-area array integration are not addressed.

Related Publications

Explore these studies to deepen your understanding of the subject.