Engineering and Technology

Scalable and highly selective graphene-based ion-exchange membranes with tunable permselectivity

A. Aixalà-perelló, A. Pedico, et al.

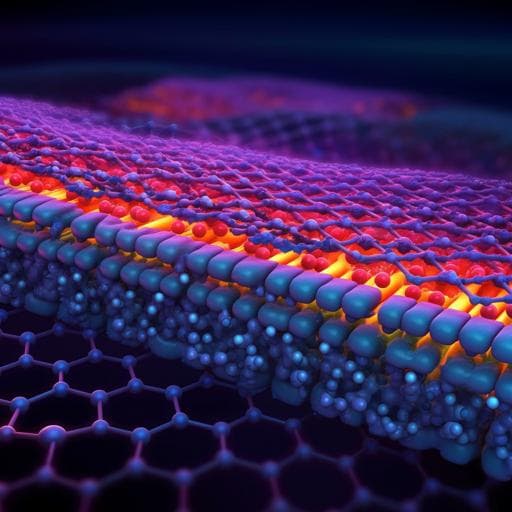

The study addresses the need for efficient, scalable, and cost-effective ion-exchange membranes (IEMs) for harvesting salinity gradient (“blue”) energy via reverse electrodialysis (RED). Conventional polymeric IEMs face trade-offs between permselectivity and ionic resistance, reduced performance in concentrated/multivalent solutions, and fouling. Graphene oxide (GO), a 2D nanomaterial with intrinsic negative surface charge and tunable nanochannels, offers a promising alternative due to charge- and size-governed ion transport, mechanical robustness, and scalable fabrication. The research aims to develop scalable GO-based cation-exchange membranes with tunable permselectivity, to elucidate how thickness, lateral flake size, partial reduction (via UV), and polymer binders affect ion selectivity, mechanical stability, and ionic resistance, and to benchmark these membranes for RED-relevant performance metrics.

The paper situates GO membranes within broader 2D-material-enabled membrane science, noting advantages in ion selectivity, mechanical stability, and antifouling. Prior work shows GO membranes achieve ion sieving via size (interlayer spacing) and charge exclusion, with surface-charge-governed transport leading to cation selectivity and asymmetric ion transport. Studies indicate cation-controlled interlayer spacing and that monovalent ions (Na+, K+) interact more strongly with GO, enhancing selectivity, while divalent ions reduce Donnan potential. Early demonstrations of graphene-based RED at micro-scale reported power densities >0.7 W m−2, but typically with small membrane areas and higher resistances. Functionalization can switch GO to anion-exchange behavior. The authors identify gaps in scaling fabrication, reducing ionic resistance, and systematically tuning permselectivity via membrane structure and chemistry.

- Materials: Commercial GO dispersion (2.5 wt%); salts (LiCl, NaCl, KCl, CaCl2, MgCl2), acids/bases (H2SO4, NaOH), NaBr, NaCH3COO, NaI; polymers PVA, PVP, PEO, PVDF, chitosan; PEEK sulfonated to SPEEK (validated via synthetic protocol and Na+ exchange).

- Membrane fabrication: Scalable doctor blade casting of GO gel on glass with controlled blade gaps to produce membranes of various thicknesses (approx. 6–40 µm in final membranes). Drying at RT or accelerated at 60 °C (no change in chemistry per XPS). Composite membranes prepared by adding binders (PVA, PVP, PEO, PVDF, chitosan, SPEEK) at GO:binder 10:1 wt ratio. Gels were mixed overnight and degassed under high vacuum for homogeneity.

- UV reduction: Partial reduction to rGO by unilateral UV irradiation (solar simulator, 6.37 W cm−2) for 10–30 min to tune surface chemistry and interlayer spacing, producing bifacial membranes (reduced surface; oxidized core for robustness).

- Flake size control: Centrifugation fractionation of GO dispersion at 1000, 2000, 3000 rpm to obtain flake lateral size categories >20 µm, 2–20 µm, and <2 µm.

- Stability tests: 1 cm² pieces immersed for 70 days in harsh solutions (H2SO4 10 M, NaOH 10 M, NaBr 5 M, NaCH3COO 5 M, NaI 10 M); post-immersion shaking (1 min) assessed mechanical/chemical integrity.

- Characterization:

- FESEM for morphology and cross-sections; EDX mapping (e.g., S, Na in SPEEK composites).

- Zeta potential (GO dispersion 0.05 mg mL−1).

- XPS (wide and HR C 1s) to assess reduction and functional groups.

- FTIR to track O–H, C=O, C=C, C–OH, C–O, epoxy groups and their evolution with UV reduction.

- XRD (Cu Kα, Bragg–Brentano) to extract interlayer distances in dry/wet states, including with NaCl intercalation (0.5 M) for application-relevant spacing.

- Contact angle (H2O, CH2I2) and surface energy (OWRK) to quantify wettability changes upon reduction.

- Electrochemical testing:

- Apparent permselectivity measured in a side-by-side flow cell (chambers 25 mL; membrane hole dia. 1.5 cm) using Ag/AgCl reference electrodes. Main electrolyte KCl with gradients (e.g., 0.1/0.5 M), plus LiCl, NaCl, CaCl2, MgCl2 for ion dependence. Corrections applied for electrode offset and junction potential (Henderson equation). Permselectivity reported with/without ion transport number corrections.

- Ionic resistance via EIS in a four-electrode cell (30 mL per side; area 1.8 cm²; NaCl 0.5 M both sides; Ti working/counter, Ag/AgCl Luggin capillaries). Frequency 1 kHz to 0.1 Hz, 5 mV amplitude. Membrane resistance from high-frequency intercept after blank subtraction. Time dependence tracked to steady hydration (~30–90 min).

- Derived maximum power density PDmax = Emem²/(4 Rm).

- Validation: Setups benchmarked with commercial FKS-30 membrane (results matched specs).

- Membrane set: Multiple samples including neat GO with varying thickness (GO-10, GO-20, GO-40), composites (PVA, PVP, PEO, PVDF, chitosan, SPEEK at different loadings/thickness), and UV-reduced (rGO-UV10/20/30).

- Scalable fabrication: Doctor blade enabled uniform, large-area GO membranes up to 14.5 cm × 14.5 cm with good mechanical flexibility (e.g., origami demonstration). Upper practical cast thickness around 50 µm due to homogeneity limits.

- Stability: GO membranes remained stable after 70 days in concentrated salts and organics; partial degradation occurred in 10 M H2SO4 and 10 M NaOH after agitation. Thicker membranes (~20 µm) showed superior stability vs thinner ones.

- Morphology: FESEM revealed uniformly stacked lamellae; composites (PVP, SPEEK) displayed homogeneous morphology; PVA composites showed agglomerates.

- Surface chemistry and reduction: UV irradiation decreased O-content (XPS), reduced C–O–C/C–OH components and produced a π–π shake-up feature, confirming partial reduction. FTIR showed decreased hydroxyl/epoxy bands with UV exposure.

- Interlayer spacing (XRD):

- GO-20: 8.3 Å (dry), 14.0 Å (wet).

- rGO-UV10/20/30: progressively reduced spacing; saturation near 20–30 min (e.g., rGO-UV20 dry 7.8 Å; wet 11.5 Å).

- Composites: larger dry spacing (e.g., GOPVA-20 9.4 Å; GOPVP-20 9.0 Å). Wet spacing: GOPVA-20 13.5 Å; GOPVP-20 15.8 Å; SPEEK wet not measured due to swelling.

- Presence of NaCl (0.5 M) in channels reduced wet spacing vs pure water (GO wet 14.0 Å vs GO+NaCl wet 12.9 Å).

- Wettability: Contact angle increased with UV time (GO-20: 60.6°; rGO-UV30: 76.4°). Surface energy decreased mainly via the polar component (SE from 47.34 to 41.51 mJ m−2).

- Permselectivity:

- Neat GO cation-selective due to negative charge; normalized permselectivity decreased with increasing external ionic strength and at very high folds (e.g., 100-fold) due to screening, swelling, and exfoliation tendencies in very dilute conditions.

- Thickness effect: Increasing from ~10 to ~30–36 µm improved permselectivity (better co-ion exclusion, less swelling) but at the cost of higher resistance.

- Flake size effect: Larger lateral flakes increased tortuosity and enhanced exclusion; smaller flakes increased capillary density and co-ion penetration, lowering selectivity.

- Binders: PVA, PVP, SPEEK composites showed improved mechanical stability; composites generally exhibited higher permselectivity, with PVP among best performers.

- UV reduction: Enhanced permselectivity via pore shrinkage and increased hydrophobicity; saturation around 10 min UV exposure (no further significant gains at 20–30 min).

- Quantitative: For GO-20 in KCl 0.1/0.5 M, potential −34.55 mV; apparent permselectivity ~91–93% depending on junction/transport-number corrections; maximum reported permselectivity reached up to 96% under optimized conditions. Cation transference number reached 0.97 at 5-fold gradient (vs ~0.6 in prior GO literature).

- Ionic resistance (EIS):

- GO-20: 4.6 Ω cm² after 1 h, decreasing to 3.9 Ω cm² after ~90 min hydration; three orders of magnitude lower than prior GO-based reports.

- Resistance increased with thickness (GO-40 ~120 Ω cm²) and with UV reduction (smaller channels).

- PVP and SPEEK composites had similar resistance to neat GO; PVA increased resistance (attributed to non-uniform distribution and smaller wet spacing).

- Power density: Maximum PDmax up to 0.54 W m−2 for GOPVP-20 under test conditions.

- Scalability and robustness: Doctor blade process produced homogeneous membranes, with composites (especially PVA, PVP) maintaining integrity in water and even in some organic solvents (e.g., propylene carbonate).

The results demonstrate that scalable GO membranes can meet key RED membrane requirements by simultaneously achieving high cation permselectivity and low ionic resistance. Structural tuning through membrane thickness, flake lateral size selection, and controlled UV reduction enables optimization of nanochannel dimensions and surface charge to balance selectivity and conductivity. UV-induced partial reduction reduces interlayer spacing and membrane polarity, enhancing exclusion of co-ions without severely compromising conductivity at short exposure (≈10 min). The addition of suitable binders (notably PVP and PVA) improves mechanical robustness in aqueous and harsh environments, which is critical for practical deployment, while preserving favorable electrochemical properties (PVP) or indicating trade-offs (PVA). The markedly low membrane resistance (≈4–5 Ω cm², dropping to ≈3.9 Ω cm² upon hydration) and high cation transference number (0.97 at 5-fold) address prior limitations of GO-based IEMs and point to the feasibility of integrating large-area GO membranes in RED stacks. The observed dependence of permselectivity on ionic strength and dilution aligns with electric double layer screening and swelling phenomena, emphasizing the need to operate within concentrations that maintain surface-charge-governed transport and structural integrity.

This work presents a scalable doctor blade approach to fabricate large-area, GO-based cation-exchange membranes with tunable permselectivity. By controlling membrane thickness, GO flake lateral size, partial UV reduction, and incorporating polymeric binders, the authors achieve up to 96% permselectivity, a cation transference number of 0.97 at a modest 5-fold gradient, and very low ionic resistance (~4.6 Ω cm², down to 3.9 Ω cm² upon hydration), leading to a maximum power density of 0.54 W m−2. UV irradiation provides a green, controllable means to tune surface chemistry and interlayer spacing, while PVP and PVA binders significantly improve mechanical stability in harsh media. These advances overcome key barriers for GO-based IEMs and support their application in RED and related ion-selective technologies. Future work should optimize long-term chemical/mechanical durability in acidic/alkaline extremes, mitigate swelling/exfoliation at very low ionic strengths, refine binder distributions (e.g., avoid PVA agglomeration), and validate performance in full RED stacks with natural feed waters and fouling considerations.

- Chemical stability is reduced in very strong acid/base (10 M H2SO4, 10 M NaOH) after agitation;

- Membrane swelling and potential exfoliation occur at very dilute conditions (e.g., 0.01 M side in 100-fold gradients), lowering permselectivity;

- Increased thickness and UV reduction elevate ionic resistance, necessitating trade-off optimization;

- PVA composites exhibit non-uniform binder distribution and higher resistance;

- SPEEK composites swell significantly (wet XRD not feasible), indicating potential hydration management issues;

- The study focuses on membrane-level metrics; full-stack RED operation, fouling behavior, and long-term stability in real feeds are not fully addressed;

- Monovalent-selectivity optimization is indicated but not comprehensively studied here.

Related Publications

Explore these studies to deepen your understanding of the subject.