Engineering and Technology

Rheologically controlled design of nature-inspired superhydrophobic and self-cleaning membranes for clean water production

K. J. Lu, D. Zhao, et al.

The study addresses the challenge of fabricating superhydrophobic, self-cleaning membranes for wastewater treatment without relying on complex surface modifications, extensive nanomaterial use, or large volumes of organic solvents. Inspired by natural non-wetting surfaces (e.g., lotus leaves), the research investigates how to create low-surface-energy hierarchical structures that sustain a stable Cassie–Baxter state, yielding high water repellence and self-cleaning. Prior approaches include depositing nanomaterials on polymer substrates, delayed NIPS with soft coagulants, VIPS with humid-air exposure, and electrospinning; each has limitations such as complexity, toxicity concerns, solvent use, or insufficient sliding angle performance. The purpose is to develop a facile, green, posttreatment-free method—spray-assisted NIPS (SANIPS)—to control phase inversion and polymer crystallization to produce PVDF membranes with high porosity and multilevel roughness, and to evaluate their anti-wetting and self-cleaning performance in DCMD with hypersaline dye wastewater. The broader significance lies in advancing scalable membrane fabrication for robust desalination and wastewater treatment with improved anti-wetting and fouling resistance.

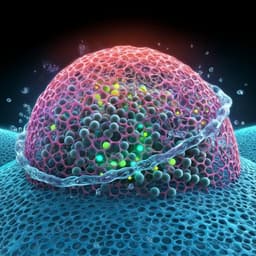

Natural superhydrophobic surfaces achieve water repellence through hierarchical micro/nanostructures that sustain a Cassie–Baxter composite interface. Artificial membranes often emulate this via increased roughness and lowered surface energy. Common methods include: (1) nanoparticle deposition (e.g., TiO2, CNTs) on polymer substrates followed by fluorinated coatings; (2) delayed NIPS using soft coagulants (alcohols, DMAc, TEP) to retard phase inversion and grow larger polymer crystals, increasing roughness and contact angle; (3) VIPS, where humid-air exposure forms a thin skin that slows subsequent phase inversion; and (4) electrospinning to create porous, hierarchical nanofiber mats, often still requiring additional hydrophobization. Table 1 surveys representative systems: contact angles up to ~160°, but sliding angles often unreported or high, and many require fluorinated modifications with cost and biodegradability drawbacks. Prior PVDF membranes via NIPS/VIPS showed enhanced hydrophobicity but typically involved organic solvents and longer processing or posttreatments. The literature highlights a gap for a green, scalable, posttreatment-free route to superhydrophobicity with low sliding angles and strong anti-wetting for MD.

SANIPS concept and mechanism: A polymer dope (PVDF in NMP with ethylene glycol as pore former/nonsolvent) is cast as a thin film (200 μm knife gap) on a glass plate at 60 °C. A brief spraying step (30 s) with compressed air, ethanol, or water is applied via an airbrush (0.3 mm nozzle; ~2 bar; 20–23 L min−1; traverse speed 5 cm s−1). For liquid sprays, an additional 5 s of compressed air aids evaporation. Ambient conditions: 25 °C, 60% RH. The spray causes convective cooling and, for liquids, localized solvent–nonsolvent exchange, inducing partial surface solidification and local surface distortion (first-level roughness). The nascent membrane is then immersed in DI water for 20 h to complete phase inversion. The initially formed top skin retards solvent–nonsolvent exchange, leading to delayed demixing, macrovoid suppression, and growth of spherulitic/crystalline features (second-level roughness). Membranes are freeze-dried for use. Controls are NIPS membranes prepared by direct immersion in water without spraying. Spray material effects: Air accelerates moisture condensation and cooling; ethanol (lower surface tension) forms finer mists and more uniform surface phase inversion; water (higher surface tension, stronger nonsolvent for PVDF) forms larger droplets, producing localized, rapid phase separation and volcano-like surface features. Characterization: Surface and cross-section morphology by FESEM; surface topology/roughness by AFM (Ra at 10×10 μm and 60×60 μm scans); phase inversion monitoring on nascent films by polarized light microscopy and mass uptake in air; surface porosity and pore size distribution from FESEM image analysis (ImageJ); mechanical properties (tensile stress, Young’s modulus) by Instron; contact angles and sliding angles by goniometry with tilting stage (6 μL droplets; tilt 1° s−1); liquid entry pressure (LEP) using a two-chamber setup with 10% NaCl and stepwise pressure increase; DCMD tests with a lab-scale module (effective area 2 cm2), feed 10 wt% NaCl + 2000 p.p.m. Rose Bengal at 60±1.5 °C, distillate DI water at 15±1.8 °C, flow rates 0.15/0.1 L min−1 (feed/distillate). Flux calculated from distillate mass change; rejection from conductivity-derived concentrations with dilution correction. Additional membranes with 3% lower PVDF concentration (SANIPS-LE, SANIPS-LW) were prepared to enhance flux for long-term DCMD (100 h).

- Superhydrophobicity and self-cleaning: SANIPS PVDF membranes (SANIPS-A/E/W) achieved water contact angles 151.9–156.2° and sliding angles 9.6–22.6°. They repelled aqueous solutions containing 0.2 mM SDS, 1% Rose Bengal, 2000 p.p.m. graphene oxide, and 10% ethanol, showing broad anti-wetting capability. NIPS control had a contact angle of ~75.8° and retained droplets even when inverted.

- Surface structure: SANIPS produced hierarchical, highly porous top surfaces vs smooth, dense NIPS surfaces. Surface porosity and pore sizes (mean ± SD): NIPS 5.6±0.2% (4.4±0.1 nm); SANIPS-A 54.4±0.1% (227.3±45.7 nm); SANIPS-E 47.6±0.2% (221.0±22.5 nm); SANIPS-W 34.5±0.1% (168.4±13.4 nm). Max surface pore sizes: 31.2±0.7 nm (NIPS), 6290.4±206.8 nm (SANIPS-A), 4069.3±126.5 nm (SANIPS-E), 1156.4±58.7 nm (SANIPS-W).

- Morphology control by spray type: Air produced spherulitic clusters; ethanol yielded uniform open coralloidal structures; water generated volcano-like humps on a relatively less porous skin. Cross-sections of SANIPS were macrovoid-free sponges, unlike macrovoided NIPS.

- Roughness: At 60×60 μm scans, roughness increased SANIPS-A < SANIPS-E < SANIPS-W; at 10×10 μm, the trend reversed SANIPS-A > SANIPS-E > SANIPS-W, reflecting micro- vs nano-scale features.

- Mechanical properties: SANIPS-W showed highest tensile stress and Young’s modulus among SANIPS variants due to smallest surface porosity/pore size and interconnected structure. SANIPS-E exceeded SANIPS-A in modulus and strength.

- Anti-wetting (LEP): All SANIPS had LEP >2 bar; SANIPS-E achieved 3.58 bar, exceeding many reported DCMD membranes.

- DCMD performance (short-term, 5 h): NIPS exhibited flux decline after ~1 h (due to wetting and fouling) but maintained >99.9% salt rejection; SANIPS membranes maintained stable fluxes and remained clean (no dye staining) with >99.9% rejection.

- DCMD performance (long-term, 100 h, 60 °C feed): Reduced-PVDF SANIPS membranes delivered high, stable flux and rejection: SANIPS-LE average flux 26.5 kg m−2 h−1, SANIPS-LW average flux 36.0 kg m−2 h−1; both maintained >99.9% salt rejection over 100 h. SANIPS-LE showed less flux fluctuation, consistent with higher LEP.

- Generality to other polymers: SANIPS increased roughness/porosity and suppressed macrovoids in PVDF-HFP and PAN. PVDF-HFP reached near-superhydrophobicity and self-cleaning; PAN became superhydrophilic due to Wenzel amplification, indicating SANIPS can tune wetting in both hydrophobic and hydrophilic polymers.

The SANIPS approach directly addresses the need for robust, scalable, and greener fabrication of superhydrophobic, self-cleaning membranes by manipulating phase inversion and crystallization kinetics through a rheologically driven spraying step. The two-stage phase inversion—rapid partial surface solidification and distortion from spraying followed by delayed demixing in water—creates hierarchical micro/nanostructures with high surface porosity that stabilize the Cassie–Baxter state, yielding high contact angles and low sliding angles. Tailoring the spray medium (air, ethanol, water) tunes microscale and nanoscale morphology, enabling optimization of roughness, mechanical properties, and anti-wetting (LEP). The resulting membranes show superior resistance to wetting and fouling in DCMD, maintaining stable high flux and >99.9% rejection even with hypersaline dye feeds over 100 h, demonstrating practical self-cleaning and durability. The generalization to PVDF-HFP and PAN highlights SANIPS as a versatile platform to enhance or invert surface wettability via roughness control, relevant across separation applications. These findings substantiate the hypothesis that controlled rheological perturbation during NIPS can engineer multilevel surface structures that improve wetting resilience and process performance without posttreatments or fluorinated coatings.

This work introduces a facile, green, posttreatment-free SANIPS process to fabricate superhydrophobic, self-cleaning PVDF membranes with hierarchical micro/nanostructures, high surface porosity, strong anti-wetting (LEP up to 3.58 bar), and excellent DCMD performance (up to 36.0 kg m−2 h−1 flux and >99.9% salt rejection over 100 h for hypersaline dye feeds). The spraying step both accelerates partial surface solidification and imposes local surface distortion, establishing multilevel roughness; subsequent delayed demixing grows robust crystalline features while suppressing macrovoids. By selecting spray media with different physicochemical properties, membrane morphology, mechanics, and wetting resistance are tunable. SANIPS generalizes to other semicrystalline polymers (PVDF-HFP, PAN) to amplify inherent hydrophobicity or hydrophilicity through roughness engineering. Future research should: (1) systematically investigate spraying parameters (nozzle type, droplet size/velocity, spray duration/coverage); (2) develop theoretical/empirical correlations linking spray physics and dope rheology/thermodynamics to morphology and performance; (3) scale-up and module-level validation under realistic operating conditions and diverse foulants; and (4) explore spray media beyond gases/liquids (e.g., suspensions) to further expand morphological control.

- Early-stage process understanding: Detailed quantitative correlations between spray parameters (droplet size distribution, velocity, impact dynamics), dope rheology/thermodynamics, and resulting morphology are not yet established.

- Parameter space: Only a limited set of spray media (air, ethanol, water), durations, and conditions were explored; nozzle types and droplet size effects remain to be systematically studied.

- Scale and geometry: Demonstrations are on flat-sheet, lab-scale membranes; scale-up, module integration, and performance under industrial conditions require further validation.

- Material scope: While PVDF, PVDF-HFP, and PAN were shown, broader polymer and dope chemistries (and long-term chemical/mechanical stability) were not comprehensively assessed.

- Application scope: DCMD tests used a specific hypersaline dye solution; broader foulant matrices and long-term anti-scaling/anti-organic fouling behaviors warrant further study.

Related Publications

Explore these studies to deepen your understanding of the subject.