Environmental Studies and Forestry

Removal and recovery of ammonia from simulated wastewater using Ti3C2Tx MXene in flow electrode capacitive deionization

N. E. Mansoor, L. A. Diaz, et al.

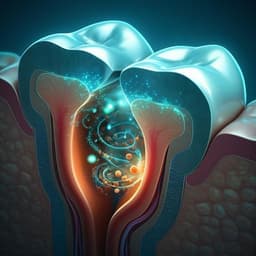

The study addresses the need for energy- and resource-efficient wastewater remediation technologies, focusing on ammonia, a prevalent and toxic contaminant in domestic, agricultural, and industrial effluents. Conventional treatments (e.g., biological nitrification, RO, distillation, and physico-chemical methods) often require substantial capital and energy, can waste valuable ammonia, and may cause cross-contamination or discontinuous operation. Capacitive deionization (CDI) is promising due to low-voltage operation and potential for ion recovery, but traditional stationary-electrode architectures require regeneration steps that increase energy use and risk cross-contamination. Flow electrode CDI (FE-CDI) enables continuous operation but typical carbon-based flow electrodes suffer from inadequate conductivity at workable loadings and poor rheology at higher loadings, leading to clogging and performance loss. The research question is whether Ti3C2Tx MXene, a highly conductive, hydrophilic, and colloidally stable 2D material with pseudocapacitive behavior, can function as a low-loading flow electrode in FE-CDI to efficiently remove and recover ammonia with high adsorption capacity, good regeneration, and low energy consumption. The purpose is to evaluate Ti3C2Tx flow electrodes in FE-CDI for simulated ammonia-laden wastewater, elucidate structure–property–performance relationships, and benchmark against activated carbon controls. The importance lies in potentially enabling scalable, continuous, and energy-efficient ammonia removal and recovery, reducing environmental impacts and conserving embedded energy and resources.

The paper surveys CDI architectures (inverted, hybrid, ultrafiltration, flow-by, desalination battery, membrane, flow-through, carbon interaction desalination, and flow-electrode CDI). Stationary-electrode CDI requires regeneration steps causing non-continuous operation and possible cross-contamination, undermining cost and energy efficiency. Carbon-based electrodes (activated carbon, graphene oxide, CNTs, composites) provide high surface area and stability but, in flow electrodes, suffer from limited conductivity at practical loadings and poor rheology at higher loadings, causing channel clogging. MXenes (e.g., Ti3C2Tx) are 2D carbides/nitrides with high conductivity, hydrophilicity, scalable production, and have been explored for remediation (heavy metals, pollutants, desalination). In conventional CDI, Ti3C2Tx has shown high salt adsorption capacities (e.g., 45–68 mg g−1) and pseudocapacitive behavior conducive to high charge efficiency near water’s electrolysis potential. However, conventional CDI suffers co-ion exclusion and requires regeneration steps, increasing energy consumption. The authors position FE-CDI with MXene flow electrodes as a way to harness MXene conductivity and intercalation-driven storage while enabling continuous operation and mitigating rheology and cross-contamination issues observed with carbon slurries.

Electrode materials and preparation:

- Activated carbon (AC) control flow electrodes: 10% w/v slurry prepared by mixing 1.20 g of 80 mesh AC in 12 mL ultrapure water, stirred 2 h, then probe-sonicated 1 h at 55 W to reduce agglomerates. During FE-CDI operation, continuous stirring prevented sedimentation.

- Ti3C2Tx MXene flow electrodes: Synthesized from Ti3AlC2 using the minimally intensive layer delamination (MILD) method by etching with in-situ generated HF from 9 M HCl and LiF at room temperature for 24 h. Post-etch washing via centrifugation to near-neutral pH, yielding a stable colloidal dispersion due to Li+ intercalation and surface terminations (–O, –F, –OH). The MXene clay was collected by vacuum filtration (0.45 µm) then redispersed in ultrapure water to 1 mg mL−1 for use as flow electrodes.

FE-CDI cell and operation:

- Architecture: Flow-electrode capacitive deionization cell incorporating titanium current collectors, vitreous carbon, carbon cloth, rubber gaskets, anion and cation exchange membranes, a spacer, and polyester filter felt (as depicted in schematic). The system was operated in batch mode.

- Feed solution: Simulated wastewater containing NH4Cl (reported as 500 mg L−1 in the abstract) flowed through the deionization module.

- Electrical operation: Constant voltage of +1.20 V (charging) and −1.20 V (discharging) applied for ion capture and release cycles.

- Controls: A 10 wt% AC slurry served as the control flow electrode material to benchmark performance.

Characterization of materials and slurries:

- XRD (Rigaku SmartLab, Cu Kα, 3–80° 2θ, step 0.03°, 5 s hold) to confirm Al removal from MAX phase and quantify (002) peak shifts and d-spacing changes before and after operation.

- Raman spectroscopy (532 nm) to identify characteristic Ti3C2Tx vibrational modes and surface terminations; assessment of exfoliation/delamination.

- Electron microscopy: SEM (FEI Tecnai field emission) and TEM (JEOL JEM-2100 HR) for morphology, flake thickness, and layered structure visualization.

- Dynamic light scattering (Brookhaven Horiba) for hydrodynamic particle size distribution; ζ-potential measurement for colloidal stability; measurements at 25 °C, pH 7.

- Viscosity measurements via rheometer using 300 µL samples, five repeats, to assess slurry rheology.

Electrochemical characterization:

- Three-electrode cell in 1 M NH4Cl to probe MXene electrochemical behavior. Freestanding Ti3C2Tx films prepared by vacuum filtration onto PVDF (0.22 µm), dried under vacuum 24 h, and cut to 1 cm². Platinum wire counter and Ag/AgCl reference (in 1 M KCl). Cyclic voltammetry (5–90 mV s−1) and galvanostatic charge–discharge collected on a Biologic SP-50 potentiostat.

Performance testing and metrics:

- Batch-mode FE-CDI runs tracked effluent conductivity ratio (C0/Ct) and current response to monitor adsorption/desorption. Ion removal efficiency, adsorption capacity (Γ), adsorption rate (Qrate), charge efficiency (η), coulombic loss (ηcoul), energy consumption, and regeneration efficiency (ηf) calculated across multiple cycles (≈10 cycles over ~30 h). AC and Ti3C2Tx performance compared directly under identical operating conditions.

- FE-CDI with 1 mg mL−1 Ti3C2Tx flow electrodes achieved 60% ion removal efficiency with a saturation time of 115 min.

- High adsorption capacity for ammonia: approximately 460 mg g−1 (with reported values around 440–460 mg g−1 across cycles), markedly higher than activated carbon controls.

- Regeneration efficiency: ~92% after stabilization (second cycle onward); inclusion of the first cycle (with irreversible site occupation) yields ~69%.

- Charge efficiency (η): 58–70% across cycles; coulombic energy not recovered (ηcoul loss) of ~8–21% typical of supercapacitive CDI behavior.

- Energy consumption: average 0.45 ± 0.01 kWh kg−1, about 10× lower than typical commercial ammonia removal in wastewater treatment plants (~4.6 kWh kg−1), while providing high adsorption capacity.

- Current response: ~30 mA under the stated operating conditions; current increased with cycles, correlating with increased electrode polarization and ηcoul.

- Adsorption rate (Qrate): Ti3C2Tx ~0.0054 ± 0.0090 mg min−1 cm−2 on average; higher than AC (~0.0021 ± 0.0003 mg min−1 cm−2). Decreasing plateau times with cycling indicated improving kinetics for Ti3C2Tx.

- Effluent conductivity ratio plateaued at ~0.410 ± 0.002 for Ti3C2Tx after stabilization versus ~0.500 ± 0.001 for AC; first Ti3C2Tx cycle showed anomalously low ratio (~0.25), attributed to non-reversible interactions at defect sites.

- Slurry properties favored Ti3C2Tx: average particle size ~1.0 µm (vs AC ~4.5–5 µm), viscosity ~0.79 mPa·s (near water; vs AC ~3.2–4.5 mPa·s), ζ-potential ~−27 mV (more stable) vs AC ~−5 to −13 mV; Ti3C2Tx required no continuous stirring and avoided channel clogging.

- Electrochemical behavior: pseudocapacitive CVs with quasi-rectangular shape and a broad redox feature (−0.35 to −0.45 V at low scan rates). Specific capacitance up to 148 F g−1 at 5 mV s−1, decreasing to ~73 F g−1 at 90 mV s−1.

- Structural evolution: XRD showed (002) peak shift from 7.29° (d ≈ 12.11 Å; interlayer ~2.70 Å considering terminations/intercalants) to lower angles after operation (e.g., ~5.585° anode; ~6.20° cathode), indicating expanded d-spacing and enhanced intercalation. TEM/SEM confirmed layered, fanned-out morphology conducive to ion access.

- Mechanistic insights: Intercalation-assisted storage complemented by surface redox and electric double-layer processes; Ti3C2Tx surface terminations (–OH, –O) promote NH4+ interactions, consistent with strong adsorption energy and charge transfer predicted for NH4+ on Ti3C2Tx.

The findings demonstrate that Ti3C2Tx MXene is an effective flow electrode material for FE-CDI targeting ammonia removal and recovery. The high conductivity, hydrophilicity, colloidal stability, and layered structure of Ti3C2Tx enable low-viscosity, stable slurries at low loading (1 mg mL−1) that maintain unobstructed flow and high electrochemical accessibility. The markedly higher adsorption capacity than activated carbon and the 60% ion removal efficiency at modest voltage (±1.2 V) indicate strong NH4+ uptake facilitated by interlayer intercalation and surface functional groups, corroborated by XRD-detected d-spacing expansion and pseudocapacitive electrochemical signatures (CV, GCD). Improved kinetics over cycles and robust regeneration (≈92%) support practical cyclic operation. Despite some coulombic losses typical for CDI, the observed charge efficiency (58–70%) and low energy consumption (≈0.45 kWh kg−1) compare favorably to conventional wastewater treatment energy demands, positioning FE-CDI with MXene electrodes as an energy-efficient alternative. The comparative analysis with AC controls underscores the importance of electrode rheology and colloidal stability in FE-CDI performance and highlights that MXenes alleviate conductivity–viscosity trade-offs that limit carbon slurries.

This work establishes Ti3C2Tx MXene as a high-performance flow electrode for FE-CDI to remove and recover ammonia from simulated wastewater. Key contributions include demonstrating high adsorption capacity (~460 mg g−1), strong ion removal efficiency (60%), good regeneration (~92%), and low energy consumption (~0.45 kWh kg−1), enabled by MXene’s conductive, hydrophilic, and layered structure with favorable surface chemistry. Electrochemical analyses (CV, GCD) and structural characterization (XRD, Raman, TEM/SEM) confirm pseudocapacitive, intercalation-assisted storage mechanisms and stable morphology during cycling. Future work should (i) test real wastewater matrices to capture complexity of co-contaminants and variable ionic strength, (ii) elucidate adsorption/intercalation kinetics and transport under different flow and pumping protocols, (iii) improve MXene oxidative stability and explore operation in non-aqueous or mixed solvents, and (iv) expand to other pollutants to assess selectivity and multi-contaminant performance for scalable, energy-efficient remediation.

- Experiments used simulated wastewater; real wastewater complexities (co-ions, organics, variable pH/ionic strength) were not tested and may affect performance and selectivity.

- First-cycle irreversible adsorption on defect sites reduced initial regeneration efficiency, indicating some fraction of non-recoverable capacity.

- Evidence of gradual oxidative/reductive degradation of Ti3C2Tx over time slightly lowered regeneration compared to AC; MXene oxidation stability remains a concern in aqueous media.

- Coulombic and energy recovery losses (≈8–21%) and increasing electrode polarization with cycling suggest room for optimization of operating conditions and electrode design.

- Results were obtained in batch mode; continuous process optimization (flow rates, residence times, pumping strategies) may alter kinetics and energy metrics.

Related Publications

Explore these studies to deepen your understanding of the subject.