Chemistry

Osmotic pressure enables high yield assembly of giant vesicles in solutions of physiological ionic strengths

A. Cooper, V. Girish, et al.

This supporting information examines how small amounts of dissolved polymer can generate osmotic pressure that counteracts increased membrane–membrane adhesion in physiological ionic strength solutions, thereby enabling high-yield assembly of giant unilamellar vesicles (GUVs). It addresses whether polymer-assisted gentle hydration can overcome electrostatic screening effects (short Debye lengths and divalent cation binding) that typically suppress GUV yields in salty buffers, and quantifies polymer concentrations, osmotic pressures, and statistical differences in yields across substrates, temperatures, lipid compositions, and buffer ionic strengths.

The work contextualizes prior methods showing sugar-doped gentle hydration produces GUVs (Tsumoto et al., 2009) and that nanoscale curvature can promote high GUV yields (Pazzi & Subramaniam, 2020). It leverages classic theory and measurements of intermolecular and surface forces (Israelachvili) to frame adhesion and electrostatic screening, including direct force measurements between bilayers and the role of calcium in adhesion/fusion (Marra & Israelachvili, 1985; Leckband et al., 1993). It cites polymer solution thermodynamics via second virial coefficients for PEG (Wang et al., 2002) to compare osmotic pressures of macromolecules versus small solutes. Additional references cover effects of dissolved gases on interfacial forces, ion-lipid interactions (Kučerka et al., 2021), divalent ion effects on bilayer structure, and material properties of agarose and PVA relevant to assisting films.

- Estimation of dissolved polymer concentrations during hydration and imaging: A 1 w/w% polymer solution (0.3 mL ≈ 0.3 g) is deposited on a 484 mm^2 coverslip. Hydration uses 0.15 mL buffer over a 113 mm^2 chamber area. Using a mass-balance scaling (Eq. S1), the maximum polymer concentration in the hydrating solution is ≈0.47 w/w%. The harvested vesicle suspension is diluted 30× into polymer-free sedimentation buffer for imaging, yielding a maximum of 0.016 w/w% polymer in the imaging chamber (assuming complete dissolution; actual solubility is lower).

- Sedimentation assessment: GUV suspensions are placed in a 1000 μm-tall imaging chamber. After 3 h, fields at z = 5 μm (imaging plane), 100 μm, and 900 μm above the coverslip are imaged for DOPC GUVs harvested from bare glass and from LGT agarose-coated glass. GUVs are abundant at the imaging plane and absent in bulk planes, indicating negligible effect of the low polymer concentrations on sedimentation.

- Literature molar yield benchmarking: From Reference 1, 63 ± 14 GUVs (10–80 μm diameter) are counted in a 20 μL aliquot from a 500 μL harvest using 1×10^-9 mol lipid. Using Eq. S2 and upper-bound assumptions (77 GUVs at 80 μm diameter, DOPC headgroup area 72.4×10^-4 μm^2, Avogadro’s number, volume scaling), the maximum molar yield is calculated. The definition of molar yield is mol lipid in GUV membranes divided by mol lipid used.

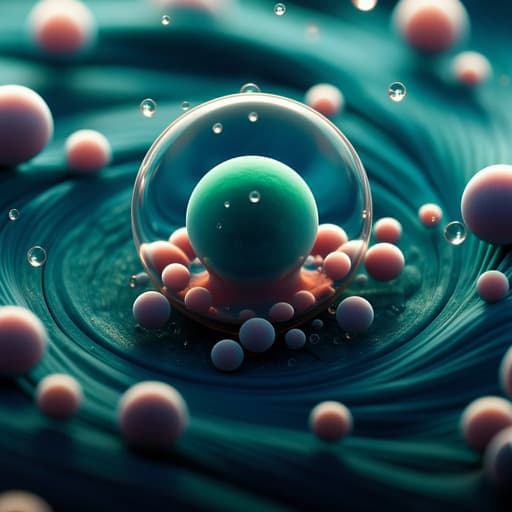

- Budding energy model: The free energy for forming spherical buds from a flat membrane templated on a surface is modeled starting from a Helfrich-based functional (Eq. S3), simplified to an effective adhesion potential and constant area budding (Eq. S4). Edge energy is neglected (assumed lipid source, no breaks). Changes in energy between low-salt and salty solutions include adhesion energy differences and osmotic pressure work terms (Eqs. S5–S6). Volume change in the disk-to-spherical bud transition and ΔP = cRT for ideal small solutes are used (Eqs. S7a–S7b) to derive a condition for equal energies between low and high salt (Eqs. S7c–S7d), yielding the required interlamellar polymer concentration (Eq. S8).

- Parameter choices for estimates: Adhesion energies: low-salt w ≈ 1×10^-6 J m^-2; salty w ≈ 1×10^-5 J m^-2. Interlamellar spacing h = 4 nm. Bud diameter ≈ 1 μm (radius 0.5 μm). Ideal gas constant and room temperature are used for ΔP = cRT.

- Macromolecular osmotic pressure: For polymers at moderate concentrations, ΔΠ includes second virial contributions (ΔΠ ≈ cRT + B2 c^2 RT/M, conceptually), implying higher osmotic pressures than ideal small solutes at the same c; hence even lower polymer concentrations could suffice than predicted by ideal Eq. S8.

- Dry polymer in interlamellar stacks: Estimated polymer mass per substrate area is 0.003 g over 4.84×10^-3 m^2. Assuming uniform stacks of 5 bilayers with 4 nm spacing, and polymer MW ≈ 120,000, the dry polymer concentration in the interlamellar volume is ≈2.58 M; only ~0.009% dissolution would meet the osmotic requirement for budding in salty solutions.

- Electrostatics: Debye screening lengths are computed using Eq. S9 with full ionic compositions (Tables S10–S11) for buffers: 100 mM sucrose; PBS + 100 mM sucrose; PBS + 5 mM MgCl2 + 100 mM sucrose; 140 mM KCl + 5 mM CaCl2 + 100 mM sucrose; 600 mM NaCl + 100 mM sucrose. pH of unbuffered 100 mM sucrose and 140 mM KCl + 5 mM CaCl2 solutions measured ≈ 5.5.

- GUV assembly conditions and statistics: GUVs assembled via gentle hydration on bare glass or polymer films (PVA; ultra-low, low, medium, and high gelling temperature agarose) at 22 °C and 37 °C, in various buffers (low-salt 100 mM sucrose; PBS±divalent ions; 140 mM KCl + 5 mM CaCl2; 600 mM NaCl), with 100 mM sucrose in all cases. Size distributions collected; ANOVA and Tukey’s HSD post hoc tests performed to compare molar yields across conditions. Additional experiments with lipid mixtures mimicking mammalian exoplasmic leaflet (MEL) and ERGIC membranes are analyzed similarly.

- Microscopy observations: In the absence of flow, dense fields of surface-attached buds are seen on LGT-agarose surfaces after 2 h; few to no free-floating structures are seen in bulk planes.

- Polymer concentration and sedimentation: The maximum possible polymer concentration in the imaging chamber is ~0.016 w/w% (assuming complete dissolution), which shows no measurable effect on GUV sedimentation; GUVs are observed at the imaging plane (5 μm) and absent at 100 μm and 900 μm planes for both bare glass and LGT agarose conditions (Fig. S1).

- Benchmarking molar yield: Using literature data (Reference 1), the maximum molar yield is calculated as 6.0×10^-4%. Restricting sizes similarly (10–100 μm), the fructose-doped technique performed here yields 3.9×10^-2%, approximately two orders of magnitude higher, yet still very low in physiological salt solutions.

- Osmotic pressure requirement: With w_low-salt ≈ 1×10^-6 J m^-2, w_salty ≈ 1×10^-5 J m^-2, h = 4 nm, and a 1 μm bud, the ideal calculation gives a required interlamellar polymer concentration c ≈ 0.2407 mM (~0.24 mM) to balance increased adhesion in salty solutions (Eq. S8). Considering polymer non-ideality (positive second virial effects), even lower polymer concentrations would suffice.

- Dry polymer availability: The estimated dry polymer concentration within interlamellar stacks is ~2.58 M (for MW ≈ 120 kDa), implying only ~0.009% of the deposited polymer needs to dissolve to provide sufficient osmotic pressure for budding in salty solutions.

- Electrostatic screening: Calculated Debye lengths: 170 nm (100 mM sucrose), 0.75 nm (PBS + 100 mM sucrose), 0.73 nm (PBS + 5 mM MgCl2 + 100 mM sucrose), 0.77 nm (140 mM KCl + 5 mM CaCl2 + 100 mM sucrose), and 0.39 nm (600 mM NaCl + 100 mM sucrose). Divalent cations at mM levels can bind/bridge charges, further enhancing adhesion at similar Debye lengths.

- Statistical comparisons of yields (selected outcomes): • At 22 °C, LGT agarose in PBS yields are not significantly different from bare glass in low salt (p = 0.347, NS); many assisting compounds (PVA, MGT, LGT) significantly increase yields versus bare glass in PBS (p ≤ 1.59E-04). Fructose-doped lipid does not improve yields versus bare glass in PBS (NS). • At 37 °C, LGT agarose in PBS yields are significantly lower than bare glass in low salt (p = 1.58E-04) but not different from bare glass in PBS (p = 0.436). Several assisting compounds significantly increase yields versus bare glass in PBS (p ≤ 8.84E-04). • For lipid composition, DOPC vs ERGIC and ERGIC vs MEL show significant differences in yield at 22 °C on LGT and on PVA; DOPC vs MEL is generally not significant. • Across ionic buffers (using LGT agarose), all physiological/high-salt buffers show significantly decreased yields versus low salt (p ≤ 2.15E-08). Yields among PBS, PBS + 5 mM MgCl2, 140 mM KCl + 5 mM CaCl2, and 600 mM NaCl are not significantly different from each other in several pairwise comparisons (NS).

The data support a mechanism in which small amounts of dissolved polymer in the interlamellar spaces generate sufficient osmotic pressure to offset the increased adhesion between membranes induced by physiological ionic strengths, enabling membrane budding and GUV formation. Electrostatic screening at high ionic strength (short Debye length) and divalent cation binding increase adhesion and reduce yields relative to low-salt conditions. Polymer films such as LGT agarose and PVA improve yields in PBS compared to bare glass, and at 22 °C, LGT in PBS can achieve yields comparable to low-salt controls. The osmotic pressure requirement is modest (~0.24 mM in an ideal estimate), and given polymer non-ideality, even lower dissolved concentrations can be effective. Importantly, the polymer concentrations in the imaging chamber are very low (≤0.016 w/w%), with no detectable impact on sedimentation or viscosity, indicating that observed yield improvements arise from interfacial assembly processes rather than bulk rheology. Collectively, these findings provide a quantitative framework for polymer-assisted GUV assembly under physiological ionic conditions and reconcile low bulk polymer concentrations with effective interlamellar osmotic action.

Small amounts of dissolved polymer can provide sufficient osmotic pressure to balance salt-enhanced membrane adhesion, enabling higher-yield GUV assembly under physiological ionic strengths. Empirically, polymer-assisted substrates (e.g., LGT agarose, PVA) increase yields in PBS relative to bare glass, with some conditions at 22 °C approaching low-salt performance. Electrostatic analyses confirm that physiological salts and divalent ions strongly enhance adhesion, consistent with reduced yields in those buffers. Theoretical estimates and stack geometry indicate that only a minute fraction (~0.009%) of deposited polymer needs to dissolve to drive budding, while overall polymer levels in the imaging chamber remain too low to affect sedimentation. Future work could refine non-ideal polymer thermodynamics in confined interlamellar spaces, quantify polymer–lipid interactions during hydration, and map optimal polymer types and concentrations across diverse lipid compositions and ionic environments.

The osmotic pressure analysis assumes ideal behavior, constant ΔP, and neglects edge energies by assuming an available lipid source; real systems involve small length scales, high local concentrations, large polymer molecular weights, partial polymer solubility, and time-dependent hydration/dissolution, all of which can induce non-ideal behavior. Potential polymer–lipid interactions are not explicitly modeled. Some buffers were unbuffered and exhibited acidic pH (~5.5), which may influence adhesion and yield. Many quantitative results are based on upper-bound estimates (e.g., size distributions, counts) to compute maximum yields, potentially overestimating actual yields.

Related Publications

Explore these studies to deepen your understanding of the subject.