Engineering and Technology

Observation of stress corrosion cracking using real-time in situ high-speed atomic force microscopy and correlative techniques

S. Moore, R. Burrows, et al.

Conjoint corrosion and stressing of a metal or alloy can result in the development of cracks which propagate through the material, causing failure due to the reduced fracture resistance. This phenomenon is known as stress corrosion cracking (SCC). Localised corrosion such as SCC can occur without obvious outward signs while causing significant deterioration of structural integrity. Subtle environmental changes can lead to considerable differences in SCC behaviour, making occurrence difficult to predict and often leading to sudden, unexpected failures across industries including gas, oil and nuclear. Techniques capable of imaging SCC processes non-destructively and in situ are critical to understand the physical mechanisms and their sequence. A range of techniques has been used—optical and electron microscopies, atom probe tomography (APT), electrochemical noise, and scanning vibrating electrode technique—spanning length and time scales, but high-resolution methods rarely permit realistic in situ conditions. The present work uses a newly developed contact-mode high-speed AFM (HS-AFM) to obtain high temporal and spatial resolution for such measurements. AFM provides topographic maps via a sharp probe; HS-AFM increases speed by orders of magnitude, enabling multiple frames per second with nanometre lateral and atomic height resolution in gaseous, liquid, or near-vacuum environments, suitable for solid–liquid interfaces and in situ corrosion studies. Here, intergranular SCC (IGSCC) was induced in thermally sensitised AISI 304 stainless steel in 395 mg L−1 aqueous sodium thiosulfate, a model system that reliably produces SCC. Thiosulfate solutions are used in numerous industries and are known to induce IGSCC in sensitised austenitic stainless steels under tensile stress. Prior studies largely used reaction sensing; visualisation had been limited to optical microscopy or post-corrosion SEM. The aim here is to provide dynamic, in situ observations of the cracking process together with high-resolution topographical, subsurface, and chemical ex situ analyses. Two principal mechanisms are discussed in the literature for sensitised 304 SS in thiosulfate: film rupture and anodic dissolution, and hydrogen-induced fracture. High crack velocities up to 8 μm s−1 have been reported, not fully explained by dissolution alone; dissolution possibly enhanced by strain-induced martensite at GBs has been proposed, while hydrogen-induced fracture has been invoked to explain brittle microcracks along multiple GBs. There is consensus that elemental sulfur at the crack tip is important, preventing repassivation by enhancing Fe and Ni dissolution at sensitised GBs and/or catalysing hydrogen entry leading to embrittlement. In this work, HS-AFM is applied to better understand the underlying mechanisms within this IGSCC system. Since IGSCC results from susceptible microstructure, environment, and local tensile stress, the study first interrogates each factor individually, and then combines them to initiate and study IGSCC. Complementary APT, EDX, and subsurface FIB/SEM analyses complete the characterisation.

The paper reviews prior SCC studies in sensitised AISI 304 stainless steel exposed to thiosulfate solutions, highlighting two dominant mechanistic frameworks: (1) film rupture with anodic dissolution at grain boundaries, potentially accelerated by strain-induced martensite, and (2) hydrogen-induced fracture producing brittle microcracks along multiple GBs. Reported crack velocities up to 8 μm s−1 suggest that dissolution alone may be insufficient to explain kinetics. The literature agrees on the importance of elemental sulfur at crack tips in suppressing repassivation and enhancing Fe/Ni dissolution and/or catalysing hydrogen ingress. Previous in situ techniques included optical microscopy, TEM, electrochemical noise, and SVET; however, the highest-resolution methods typically lacked the environmental compatibility for in situ observation. Direct dynamic visualisation of mechanisms, especially at the nanoscale in liquid, had been limited prior to HS-AFM.

Materials and preparation: AISI 304 stainless steel (1 mm sheet, Goodfellow) was thermally sensitised at 600 °C for 70 h, air cooled, and sectioned into 20 × 5 mm rectangles or 3.5 mm wide dog-bone shapes. Composition was measured by ICP-OES/combustion analysis. Surfaces were mechanically polished from SiC P120 to P4000, then 3–0.25 μm diamond pastes, followed by 12 h vibropolishing in colloidal silica. Samples were thoroughly cleaned (water/detergent, acetone, ethanol, isopropanol, Milli-Q water). EBSD characterised grain size and orientations. High-speed AFM: A contact-mode HS-AFM (Bristol Nano Dynamics Ltd.) with interferometric detection provided height sensitivity ±15 pm. Imaging was performed in liquid using a contact-mode MSNL-10 cantilever in a bespoke piezo flexure stage. Real-time data were acquired with custom software and processed in Gwyddion 2.53; an integrated 20× optical microscope aided feature identification. In situ environmental conditions: Corrosion environment was 395 mg L−1 aqueous sodium thiosulfate. Time-lapse HS-AFM imaging of localised corrosion was performed without applied stress (example frame acquisition time 0.5 s). Stress application and SCC tests: A micro three-point bend rig enabled tensile stressing during immersion. Pre-exposure to thiosulfate was varied from 0–20 days; optimal initiation was achieved by a 6-day pre-exposure, after which samples were plastically bent by 1.00 ± 0.01 mm (yield stress), producing a local maximum strain ~0.02 at the apex (modelled). SCC initiation typically occurred within 1 day of stressing; through-width failure (3–5 mm) occurred over hours. HS-AFM monitored regions ahead of visible crack tips at frame rates up to 2 s−1 to capture initiation and early propagation. Ex situ HS-AFM: Post-failure samples were mounted in transparent acrylic, repolished, and imaged in deionised water to characterise cracked and uncracked GBs. FIB/SEM: An FEI Helios NanoLab 600 dual-beam (Ga+ source) performed serial sectioning and imaging to reveal subsurface crack networks. FIB milling used 30 kV, 6.5–20 nA; SEM imaging used 10 kV, 0.34 nA at 52° tilt. EDX and EBSD: Conducted on a Zeiss Sigma VP FEG-SEM with EDAX EDX (30 kV, 120 μm aperture); data processed with TEAM V4.1 and OIM software. Atom Probe Tomography: Site-specific FIB lift-out prepared needles from an arrested crack tip region, guided by an electron-beam-deposited Pt fiducial. Needles were annularly milled to ~50 nm tip radius; seven needles were prepared. A Cameca LEAP 5000 XR operated in laser pulsing mode (50 pJ, 200 kHz, 50 K, 0.5% detection rate). 3D reconstructions used a 37 at.% oxygen iso-concentration surface to delineate oxide from metal; proximity histograms quantified compositional gradients.

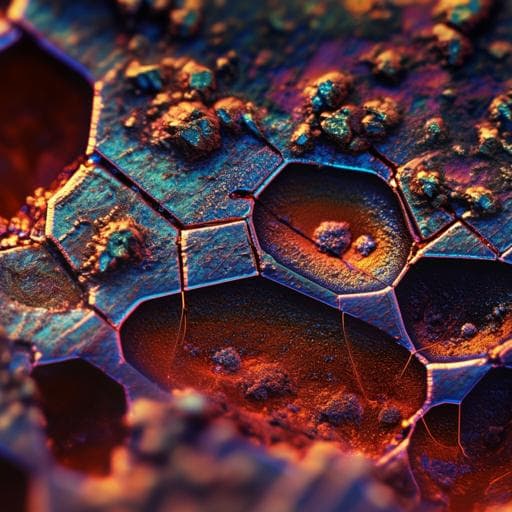

- HS-AFM visualised nanoscale features of sensitised 304 SS: GB carbide precipitates (~30–300 nm) and slip bands; slip step heights down to ~0.5 nm (two dislocations). EBSD showed grain diameters from ~1–43 μm (avg ~15 μm). - In thiosulfate without applied stress, preferential attack occurred at GB carbide sites, producing intergranular micro-pits; carbide-associated features diminished but carbides were not universally dissolved. - During in situ SCC, grain boundary uplift of tens of nanometres was observed ahead of crack tips. Uplift was localised to cracking regions and exceeded relief from mechanical deformation alone, suggesting subsurface processes and/or oxide formation. - Real-time HS-AFM captured crack propagation as a smooth, continuous process at the surface, not stepwise; an example apparent velocity was ~23 nm s−1 between sequential frames (slower than literature reports of up to 8 μm s−1). - Ex situ HS-AFM on cracked samples showed widened cracked GBs (~2× width of non-cracked GBs). Carbide precipitates remained along one side of cracked GBs, implying asymmetric dissolution of Cr-depleted regions adjacent to carbides. - APT at an arrested crack revealed a layered oxide on crack walls: an inner Cr-rich oxide (Cr peak up to ~18 at.% near 0.5 nm from the interface), overall oxide thickness ~20 nm. The GB/oxide interface exhibited severe Cr depletion (~6.8 at.%) and Ni enrichment (up to ~18 at.%). Na was detected outside the oxide, consistent with retained electrolyte in a porous outer oxide. - FIB/SEM serial sectioning ahead of surface crack tips revealed a network of subsurface intergranular cracks lined by porous oxide; oxide thickness varied from tens to hundreds of nanometres and did not fill the GBs, consistent with stress-driven propagation. - The oxide thickness scale was comparable to the observed GB uplift, supporting a mechanistic link between pre-oxidation and uplift. - Evidence collectively indicates subsurface-dominated crack advance with local chemical modification (oxide formation, Cr depletion, Ni enrichment) facilitating mechanically driven rupture.

The study addresses the challenge of directly observing SCC mechanisms at relevant spatial and temporal scales. By isolating and then combining microstructure, environment, and stress, HS-AFM provided real-time surface morphology evolution, while APT and FIB/SEM supplied composition and subsurface structure. The observed GB uplift ahead of crack tips, with magnitudes comparable to measured oxide thicknesses, suggests that oxidation at or ahead of subsurface GBs can induce local volumetric expansion or structural modification manifesting as surface uplift. Subsequent applied tensile stress appears to rupture this oxide-weakened boundary, enabling stress-driven crack advance. The smooth, continuous crack extension observed at the surface contrasts with previously reported stepwise microcracking attributed to hydrogen fracture; while subsurface behaviour could still involve intermittent events, the present data support a dominant role for pre-oxidation/film rupture coupled with mechanical loading. APT revealed severe GB sensitisation (Cr ~6.8 at.%) and Ni enrichment (~18 at.%) at the oxide interface, consistent with preferential dissolution and altered passivation behaviour at sensitised GBs. The layered oxide, porous and not filling GBs (tens to hundreds of nanometres thick), further supports a non-passivating, deposited corrosion product facilitating stress-controlled crack propagation. The synergy of chemistry and mechanics is evident: thiosulfate-induced GB modifications produce weakened interfaces that localise stress; limited diffusion in an occluded subsurface crack interior sustains aggressive chemistry; and local deformation (slip, potential martensite) concentrates ahead of tips. HS-AFM proved particularly powerful for capturing initiation and very early propagation before tip-convolution artefacts dominate, complementing bulk and subsurface techniques. Overall, the findings refine SCC models for this system, favouring a stress-driven film rupture mechanism with pre-oxidation, while not excluding contributions from hydrogen-assisted processes.

This work demonstrates that in situ contact-mode HS-AFM, combined with correlative APT, FIB/SEM, EDX, and EBSD, yields new mechanistic insight into intergranular SCC of sensitised AISI 304 in thiosulfate solution. Newly reported phenomena include grain boundary uplift preceding visible cracking, a layered oxide on crack walls with an inner Cr-rich layer, severe GB Cr depletion with Ni enrichment at the oxide interface, and a predominance of subsurface crack propagation with porous oxide that does not fill GBs—consistent with stress-driven fracture of oxide-weakened boundaries. Surface crack propagation appeared smooth and continuous at the observed scales. These observations support a model where pre-oxidation at or ahead of the subsurface crack tip weakens GBs and induces uplift, followed by mechanically driven rupture (film rupture), while other mechanisms (e.g., hydrogen effects) may contribute. Future work should focus on deconvoluting sulfur signals in APT mass spectra, quantifying uplift–oxide relationships spatiotemporally, extending HS-AFM to different alloys and environments, and integrating electrochemical measurements to link local chemistry with mechanical evolution for SCC mitigation strategies.

- HS-AFM tip–surface interaction may influence local mass transport (potential stirring or diffusion hindrance), affecting reaction rates and observed timescales; however, no reactions were seen in non-corrosive media. - AFM imaging suffers from tip convolution and loss of resolution as cracks deepen and widen, limiting quantitative analysis to initiation and early propagation. - The measured surface crack velocity (~23 nm s−1) was derived from two frames and may not represent overall kinetics. - Observations of smooth propagation were surface-based; subsurface cracking could proceed in a stepwise manner. - APT analysis could not conclusively quantify sulfur due to mass-to-charge overlap (32 Da, S vs O2), limiting direct assessment of sulfur’s role. - Porous oxide and retained electrolyte complicate chemical attribution (e.g., Na presence) post-testing. - Environmental and mechanical boundary conditions in the micro-bend setup may not fully replicate service conditions.

Related Publications

Explore these studies to deepen your understanding of the subject.