Engineering and Technology

Nanoporous amorphous carbon nanopillars with lightweight, ultrahigh strength, large fracture strain, and high damping capability

Z. Li, A. Bhardwaj, et al.

This groundbreaking study by Zhongyuan Li and colleagues explores the creation of nanoporous carbon nanopillars that achieve remarkable lightweight and ultrahigh strength properties. With a yield strength surpassing most engineering materials, these pillars uniquely exhibit elastic and plastic behaviors alongside impressive damping capabilities, paving the way for innovative applications in structural engineering.

~3 min • Beginner • English

Introduction

The study addresses the long-standing challenge of achieving lightweight materials that also combine ultrahigh strength, large deformability, and high damping capability. Traditional approaches struggle because strength scales with mass density, and many fabrication methods cannot realize nanoscale ligament dimensions that leverage size effects (“smaller is stronger”) and flaw tolerance to boost both strength and ductility. Nanoporous materials offer a route to reduce density while retaining high effective strength due to nanoscale ligaments. However, existing methods for nanoporous metals/ceramics often limit ligament thickness to ~50–100 nm and involve heavy constituent densities, limiting specific strength. Carbonaceous materials, especially amorphous carbon, promise high specific strength. The purpose of this work is to develop an economically scalable method to fabricate fully dense and nanoporous amorphous carbon nanopillars with tunable porosity and nanoscale ligament thickness, enabling systematic mechanical characterization. The study aims to demonstrate simultaneous lightweight, ultrahigh strength, large fracture strain, and high damping capability, and to reveal the underlying deformation mechanisms (notably local sp2-to-sp3 transitions).

Literature Review

Nanoporous materials (<100 nm pore size) possess high surface area and tunable topologies, enabling applications in separations, catalysis, energy storage, biomedicine, and more. Mechanical advantages include high strength-to-weight ratios. Established fabrication routes include dealloying and hard/soft templating, microwave irradiation, additive manufacturing, ion-beam, and laser processing. Nanoporous metals/ceramics typically achieve 10–200 MPa strength at densities of 1–10 g cm−3, but have limitations: (i) dealloying/templating generally restrict ligament thickness to ~50–100 nm, limiting maximization of size-strength effects and ductility improvements due to flaw tolerance; (ii) metals/ceramics have lower specific strength due to high density. Recent approaches produced nanoporous amorphous carbons (via sequential dealloying, templating, two-photon lithography), achieving sub-50 nm ligaments and tunable architectures, but two-photon lithography is costly and slow, and prior works focused mostly on electrochemical/biocompatibility rather than comprehensive mechanical property mapping with scalable methods. There is a need for scalable synthesis with precise porosity and length-scale control to enable statistically robust mechanical evaluation and comparison to structural materials.

Methodology

Fabrication: Films (~5 µm) of self-assembled nanocomposites comprising PDMS-b-PEO bottlebrush block copolymers (BBCP) as sacrificial porogens and phenol-formaldehyde (PF) resin as carbon source were spin-coated (1000 rpm, 30 s) on cleaned Si wafers (IPA and DI water ultrasonication, 10 min each; UV-ozone 15 min). Nanoimprint lithography (NIL) used h-PDMS stamps: imprint at 170 °C, 180 psi for 10 min to transfer patterns while crosslinking PF. After cooling, stamps were removed. Carbonization: tube furnace under N2 at 750 °C for 1 h (10 °C min−1 ramp), degrading BBCP and converting PF to carbon, yielding mesoporous carbon. Residual surface film removed by O2 plasma reactive ion etching (HF power 10 W, 12 mtorr, O2 40 sccm, 90 s). Fully dense controls fabricated identically but without BBCP.

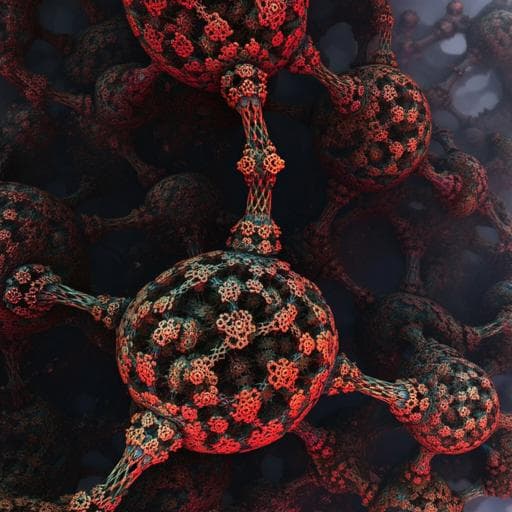

Structures: Nanopillars ~300 nm diameter, ~1 µm height, prepared at porosities 0, 40, 46, 51, and 59%, giving densities 0.66–1.6 g cm−3. Pore size ~50 nm typical; ligand thickness down to ~20 nm or thinner; additional pore-size tuning via BBCP molecular weight (250, 500, 750 kDa) at BBCP:PF = 1:2 produced pore sizes with 51% porosity: small 21.8 ± 3.3 nm, medium 39.4 ± 4.0 nm, large 79.4 ± 10.0 nm. Uniform porous architecture confirmed by SEM/HRTEM; amorphous nature by HRTEM and SADP (halo rings ~1.15 Å and ~1.95 Å).

Materials synthesis: PDMS-b-PEO BBCP synthesized by ROMP using Grubbs III catalyst; molecular weights 250, 500, 800 kDa. PF resin synthesized in basic medium (phenol with NaOH; formaldehyde molar ratio 2:1 to phenol; 70 °C for 1 h; neutralization, solvent exchange and THF redissolution). BBCP and PF solutions (THF, 40 and 50 mg mL−1) mixed at weight ratios 1:1.5, 1:2, 1:3, 1:4, concentrated to ~300 mg mL−1 prior to coating. Ratios ≤1:1 avoided due to fragile imprinting.

Mechanical testing: In situ uniaxial compression of nanopillars in SEM (Nanoflip nanoindenter, flat diamond tip) at constant displacement rate 10 nm s−1; stress–strain via Sneddon correction; yield strength defined at 1% plastic strain using offset method (line with slope E through 0.01 strain). Cyclic compression: six cycles between −95% of average fracture stress and 12% of that maximum, at 25 nm s−1. Nanoindentation (iNano, Berkovich tip) on adjacent thin films at 0.2 s−1 strain rate; depths ~1/10 film thickness to avoid substrate effects. FIB-milled micropillars (2 µm dia, 6 µm height) used for size-effect checks.

Characterization: SEM for morphology; HRTEM/TEM (Titan Themis AC-STEM, 300 kV) with cross-sectional lamella prep by FIB; EELS at 250 kV; sp2 fraction via two-window integration (1s-π*: 282–286 eV; 1s-σ*: 288–298 eV). Raman (633 nm) before/after ~35% compressive strain, Gaussian fitting of D (~1380 cm−1) and G (~1560 cm−1) bands.

Simulations: Amorphous carbon model at 1.6 g cm−3 with ~90% initial sp2 fraction generated via liquid-quench methods; LAMMPS (version 2021-09-29) with AIREBO potential. Equilibration 500 ps (NPT, 300 K, 0 MPa), then loading–unloading NEMD at 300 K with strain rate 1×10^8 s−1, timestep 0.2 fs (N_o ε τ ensemble). Hybridization assigned by nearest-neighbor coordination within 2.0 Å (sp: 2, sp2: 3, sp3: 4 neighbors).

Key Findings

- Fabrication and structure: Scalable NIL of self-assembled BBCP/PF nanocomposites yields fully dense and nanoporous amorphous carbon nanopillars (~300 nm diameter, ~1 µm height) with porosities 0–59%, pore sizes down to ~22 nm, and ligament thickness ~20 nm or below. HRTEM/SADP confirm amorphous structure with smooth pore surfaces and no detectable critical surface flaws.

- Density: Fully dense pillars ~1.6 g cm−3; nanoporous pillars 0.66–0.82 g cm−3 depending on porosity.

- Elasticity and strength: Young’s modulus and strength decrease with increasing porosity; scaling with relative density follows E ~ ρ^1.42 and σ_f ~ ρ^2.03. Yield and fracture strengths reach 50–75% of the Suquet upper bound across porosities, exceeding the typical 20–25% efficiency seen in cellular solids.

- Deformability: Large elastic strain up to ~13% and fracture strain up to ~35% observed. Fracture occurs via shear banding.

- Transition in ductility: A non-monotonic transition in fracture and plastic strains occurs as porosity increases (notably higher fracture strain at 59% porosity than at 51%) and as pore size decreases at fixed porosity (51%). Increased plasticity correlates with ligament thickness approaching ~10 nm or less (e.g., ~11.3 nm at 59% porosity; ~7.2 nm at 51% with small pores), consistent with nanoscale flaw tolerance.

- Damping: Pronounced mechanical hysteresis in cyclic compression; loss factor η up to 0.033 (high damping range, comparable to Nitinol Ni–Ti shape memory alloys with η ≈ 0.028–0.041). Nanoporous pillars generally show lower η than fully dense ones, attributed to mixed stress states in bending ligaments, but η increases when ligaments become extremely thin.

- Mechanism: EELS shows sp2 fraction reduction of ~4% in highly deformed regions (~98% → ~94%), indicating sp2-to-sp3 transition. Raman reveals increased D peak intensity and positive G peak shift after ~35% compression, consistent with increased sp3 content and local topological changes (e.g., folding/curvature). MD simulations show sp3 fraction increases by ~13% at 40% strain, with partial reversibility upon unloading; permanent ~3.7% reduction in sp2 bonds, matching EELS. Nonlinear slope changes in unloading in both experiment and simulation explain hysteresis.

- Size effect and flaw absence: FIB-fabricated micropillars (2 µm dia) exhibit similar properties to nanoimprinted pillars, indicating robustness up to micrometer scale and lack of critical flaws. Smooth pore surfaces and nanoscale ligament thickness sustain ultrahigh specific strength despite increased surface area.

- Performance landscape: Compared to materials of similar density, these nanopillars lie among the strongest and most deformable; they occupy a previously unfilled region of specific yield strength vs. specific Young’s modulus, with exceptionally high specific modulus of resilience (estimated on the order of ~50,000 J kg−1).

Discussion

The results demonstrate that combining NIL with self-assembled BBCP/PF nanocomposites yields amorphous carbon nanopillars that simultaneously achieve low density, ultrahigh strength, large elastic and plastic strains, and high damping—properties typically considered mutually exclusive. The key enablers are nanoscale ligaments (leveraging “smaller is stronger” and flaw tolerance) and a deformation mechanism governed by local sp2-to-sp3 transformations: reversible portions enable large elastic recovery and high energy dissipation (hysteresis), while irreversible portions produce substantial plasticity without visible cracking, culminating in fracture strains up to ~35%. The observed scaling (E ~ ρ^1.42; σ_f ~ ρ^2.03) and strengths reaching 50–75% of the Suquet upper bound underscore the architectural efficiency and absence of detrimental defects.

Compared to state-of-the-art amorphous carbon nanolattices that are ultra-strong but brittle, the present nanopillars are markedly more deformable and exhibit significant damping capacity, while also being fabricated rapidly and scalably with minimal shrinkage. The materials achieve an unprecedented combination of specific yield strength and specific modulus, implying exceptionally high specific modulus of resilience and energy absorption/release potential. The non-monotonic ductility transition with decreasing ligament thickness (~10 nm threshold) provides a design guideline: thinner ligaments can increase plasticity and damping even within nanoporous geometries where mixed stress states typically suppress the sp2-to-sp3 transition in tensile regions. Overall, the findings validate the hypothesis that tunable nanoporosity in amorphous carbon can maximize size effects and controlled hybridization transitions to achieve a superior multifunctional mechanical property set.

Conclusion

This work introduces a rapid, scalable NIL-based route to fabricate fully dense and nanoporous amorphous carbon nanopillars with precisely tunable porosity (0–59%), pore size (~22–80 nm), and nanoscale ligament thickness (~20 nm or below). The resulting materials combine ultralow density (0.66–1.6 g cm−3) with ultrahigh specific strength, large elastic strain (~13%), large fracture strain (up to ~35%), and high damping (loss factor up to 0.033), with strengths attaining 50–75% of the Suquet upper bound. Experimental (EELS, Raman, cyclic compression) and atomistic simulations reveal that reversible and irreversible sp2-to-sp3 transitions, together with nanoscale ligament size effects, govern elasticity, plasticity, and hysteresis. The nanopillars populate a previously unoccupied performance space in specific modulus vs. specific strength, indicating exceptional specific modulus of resilience.

Future directions include: exploring alternative pore architectures to approach the Suquet upper bound further; theoretical modeling of the ~10 nm critical ligament thickness for ductility transitions; scaling studies to millimeter–centimeter dimensions to assess size effects and defect statistics; and integrating additional functionalities (e.g., embedded nanoparticles, ALD coatings, bimodal pore distributions) for application-tailored performance in aerospace, military, energy, biomedical, filtration, and catalysis.

Limitations

- Scale effects: While micropillar tests (2 µm diameter) showed similar properties to nanopillars, behavior at larger, bulk-like scales remains untested; statistical occurrence of weak spots may emerge at millimeter–centimeter scales.

- Critical thickness understanding: The observed ductility transition near ~10 nm ligament thickness lacks a quantitative theoretical framework; geometry, atomic arrangement, and plasticity mechanisms require further modeling.

- Headroom to bounds: Despite high efficiency, strengths remain below the Suquet upper bound, suggesting architectural optimization could yield further gains.

- Simulation constraints: MD used high strain rates inherent to NEMD, leading to elevated stress levels; while strain-governed transitions are captured, quantitative stress values are rate-influenced.

- Mixed stress states: In nanoporous pillars, bending-induced tensile regions can suppress the sp2-to-sp3 transition, reducing plasticity and damping relative to fully dense pillars; optimizing architecture to mitigate tensile regions may be necessary for maximal damping.

- Process notes: Although shrinkage is low (<20%), precise control across very large areas and very thick films may pose engineering challenges that were not fully evaluated here.

Related Publications

Explore these studies to deepen your understanding of the subject.