Engineering and Technology

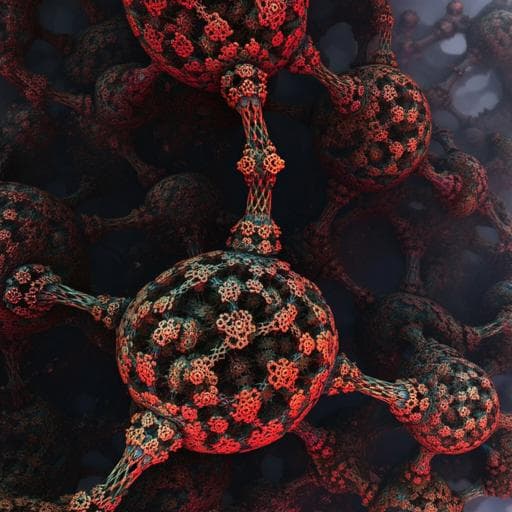

Nanoporous amorphous carbon nanopillars with lightweight, ultrahigh strength, large fracture strain, and high damping capability

Z. Li, A. Bhardwaj, et al.

This groundbreaking study by Zhongyuan Li and colleagues explores the creation of nanoporous carbon nanopillars that achieve remarkable lightweight and ultrahigh strength properties. With a yield strength surpassing most engineering materials, these pillars uniquely exhibit elastic and plastic behaviors alongside impressive damping capabilities, paving the way for innovative applications in structural engineering.

~3 min • Beginner • English

Related Publications

Explore these studies to deepen your understanding of the subject.