Medicine and Health

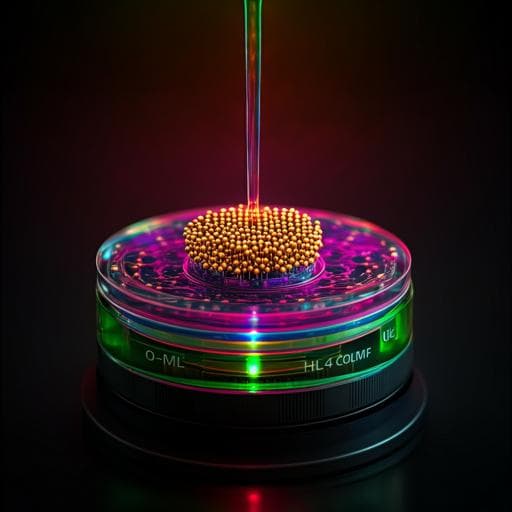

Monolithic integration of nanorod arrays on microfluidic chips for fast and sensitive one-step immunoassays

Y. Wang, J. Zhao, et al.

Discover how a team of researchers, including Ye Wang and Jiongdong Zhao, have developed innovative nanorod arrays on microfluidic chips that revolutionize fast and sensitive flow-through immunoassays. With unprecedented sensitivity and rapid results for cardiac marker detection, this breakthrough paves the way for enhanced point-of-care diagnostics.

Related Publications

Explore these studies to deepen your understanding of the subject.