Chemistry

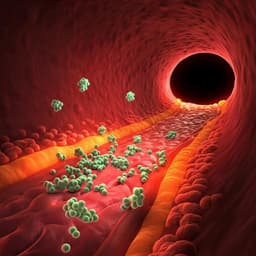

Methyl formate as a hydrogen energy carrier

R. Sang, Z. Wei, et al.

Discover the exciting research by Rui Sang, Zhihong Wei, and colleagues on methyl formate as a groundbreaking hydrogen storage material. Their innovative approach to hydrogen production highlights rapid efficiency and selectivity under mild conditions, opening new possibilities for clean energy applications.

Playback language: English

Related Publications

Explore these studies to deepen your understanding of the subject.