Chemistry

Mechanical cleaning of graphene using in situ electron microscopy

P. Schweizer, C. Dolle, et al.

This groundbreaking research by Peter Schweizer and colleagues unveils a novel site-specific mechanical cleaning technique leveraging in situ electron microscopy. This method promises to effectively eliminate surface contamination from 2D membranes like graphene, enhancing experimental accuracy and paving the way for advances in nanocrystalline graphene synthesis.

~3 min • Beginner • English

Introduction

The study addresses the persistent problem of contamination on two-dimensional (2D) materials, particularly graphene, where even single adsorbates can significantly alter properties and complicate characterization and controlled surface chemistry. Existing cleaning techniques (thermal annealing, plasma, laser, chemical activation, current-induced, and initial AFM-based mechanical approaches) have not consistently delivered site-specific, fully atomically clean regions, and many methods are incompatible with sensitive samples. The research question is whether a site-specific, non-thermal, mechanical approach conducted in situ in electron microscopes can achieve atomic-scale cleanliness on both sides of suspended graphene membranes, elucidate recontamination mechanisms under vacuum and electron-beam exposure, and leverage this understanding to enable targeted in situ synthesis on cleaned areas.

Literature Review

Prior work has explored multiple graphene cleaning methods: heating/annealing (including high-temperature UHV aging), plasma treatments, laser cleaning, chemical activation strategies, and current-driven cleaning. Mechanical cleaning using AFM has been attempted but did not achieve atomically clean membranes. While some methods yield improvements, they lack spatial control over clean regions and can introduce energy or reactive species that are incompatible with sensitive or functionalized samples. Contamination from PMMA used in transfer is a notable source, and electron-beam-induced contamination growth in microscopy is a known issue. There remains a need for a controllable, site-specific, low-energy cleaning technique that can achieve atomic-scale cleanliness and provide insight into recontamination dynamics.

Methodology

Overview: The authors developed an in situ mechanical cleaning technique analogous to sweeping with a nanoscale 'broom'—a fine metal tip mounted on piezo-driven micromanipulators—to mechanically separate adsorbed contaminants from graphene without damaging the lattice. The approach is implemented in both SEM and TEM to clean both sides of suspended membranes.

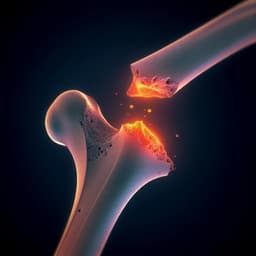

Physical principle: Cleaning relies on the disparity between strong intralayer covalent bonding within graphene and comparatively weak van der Waals interactions between contaminants (e.g., PMMA residues) and graphene. A tip pressed with sufficient normal force into contact sweeps laterally to unzip these weak bonds, displacing adsorbates while preserving graphene’s lattice.

SEM implementation: Conducted in a FEI Helios NanoLab 660 dual-beam FIB/SEM. Two independent three-axis micromanipulators (Kleindiek MM3A) equipped with as-received tungsten tips (radius ~50–150 nm; ~100 nm typical) were used, one for each side of a suspended membrane. Surface-sensitive secondary-electron imaging at 2 kV visualized contamination; STEM at 20–30 kV was used as needed. Cleaning proceeded by bringing a tip into contact (visual approach using depth-of-field and observing membrane deflection), then sweeping to remove contamination from one side, repeating from the opposite side until fully cleaned. Perspective views were obtained by tilting ~80° to observe induced wrinkles/topography.

TEM implementation: Performed in an aberration-corrected FEI Titan Themis 300 at 80 kV (to avoid knock-on damage). A Nanofactory STM holder provided a single three-axis manipulator outfitted with a custom crescent-shaped gold double tip (fabricated by electrochemical etching and FIB milling) to access both sides of the membrane sequentially. Imaging included CTEM, HRTEM with a monochromator, and EELS (Gatan GIF Quantum, 115 mm camera length, 2.5 mm aperture). Sample size was limited to a 3 mm half-grid due to holder geometry.

Sample preparation: CVD graphene (“Trivial Transfer Graphene,” ACS Materials) was released in DI water, picked up with filter paper, cut to ~2×2 mm², transferred to Quantifoil TEM grids, and PMMA support removed (20 s acetone bath + 2 h acetone vapor exposure). This process leaves residual PMMA typical of standard transfers.

Cleaning protocol: Fresh suspended graphene membranes (mono-, bi-, and trilayer) with residual organic contamination were cleaned by sequential sweeping from both sides. Contamination often adhered to the tip, increasing effective contact area and aiding removal; larger rigid debris could be pushed to edges. Cleaning durations were typically ~6 min (SEM) and ~11 min (TEM), limited by SEM refresh rate (~0.5 Hz) and sequential double-tip approach in TEM; with faster SEM scanning, ~1 min cleaning was achievable. Raman spectroscopy post-cleaning showed no increased D-band, no shifts in G/2D bands, indicating no defect introduction.

Force measurements: A Kleindiek STMFA spring-table system (11 N/m calibration) recorded forces during SEM cleaning using template-matched deflection tracking in custom Python/OpenCV routines. Two geometries (top-down and perspective) allowed separation of lateral and normal components. Typical lateral cleaning force Fc ≈ 76.6 ± 11 nN; minimal normal force to achieve cleaning ≈ 50 nN (often exceeded up to 1.6 µN during operation to ensure contact). Membrane rupture threshold with used tips ~7.5 µN. Frictional component was assumed <1 nN; adhesion dominated. Estimated adhesion energy Ea ≈ 0.36 ± 0.05 J/m² from Fc−area analysis, consistent with graphite cleavage energy and organic desorption energies. For interconnected contamination removed in larger chunks, higher lateral forces were needed; a general relationship of ~6.7 µm⁻² (MPa) for removing arbitrarily sized contamination was observed, comparable to graphite interlayer shear strength. Success rates >80% on freshly prepared membranes.

Analytical characterization: HRTEM of cleaned regions showed pristine graphene lattice; only intrinsic defects (e.g., divacancies) were observed. EELS on as-prepared vs. cleaned membranes showed disappearance of the oxygen K-edge after cleaning (consistent with PMMA removal) and a plasmon loss peak shift from ~22 eV (PMMA-like) to ~16 eV (monolayer graphene-like), with improved C K-edge fine structure despite brief air exposure.

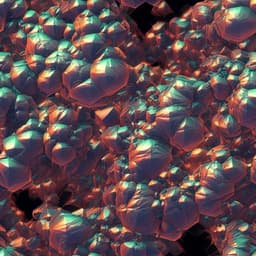

Recontamination studies: Ex situ exposure of cleaned membranes to ambient air for 5 min led to substantial recontamination (TEM showed discontinuous film with small clean patches; SEM showed continuous layer), reflecting differences in evacuation speed and vacuum levels (SEM ~10⁻⁵ mbar vs TEM ~10⁻⁷ mbar). In situ under the beam, clean membranes developed nanoscale amorphous contamination seeds under moderate electron dose (20 kV, 69.1 µA mm⁻²), preferentially at defects; seeds grew and coalesced over time. Space–time analyses (x–t slices) quantified area coverage growth, with an initial low-rate seed nucleation phase followed by linear growth and acceleration with additional seeding. Scan-rate experiments at identical dose rates compared slow (30 s per pass) vs fast (~0.7 ms per pass, 50 ns dwell) scanning: slow scanning produced uniform recontamination; fast scanning led to thicker contamination at scan-pattern edges and less in the center, indicating surface diffusion of precursors dominates over gas-phase supply. From edge accumulation and scan timing, a mean squared displacement analysis yielded a surface diffusion coefficient D ≈ 4.88×10⁻12 m² s⁻¹ for the mobile species, smaller than literature values for benzene and n-alkanes on graphite, implying larger, less mobile hydrocarbons.

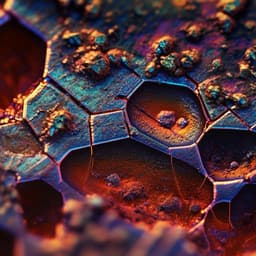

In situ synthesis using supplied precursor: Leveraging surface diffusion from contaminated surroundings, the authors deposited copper(II)-tetraphenylporphyrin (CuTPP) in dimethoxyethane onto graphene (including variants with chemical activation and covalent attachment) by drop-casting and rinsing to leave non-volatile residues. After mechanically cleaning a window, molecules diffused into the clean area and electron-beam exposure induced cross-linking and conversion, yielding growth of a second graphene layer starting at the illuminated area edges. Within ~6 min, a continuous second layer formed, with occasional initiation of a third layer. Fourier filtering of HRTEM separated layers: the new layer was nanocrystalline, turbostratically disordered (random in-plane orientations with [0001] texture), grain sizes of only a few nanometers, and grain boundaries composed of dislocation walls with 5–7 and 5–5–8 ring configurations. The process likely involves radiolysis/knock-on fragmentation of CuTPP and incorporation into the graphene lattice (Cu not clearly observed).

Key Findings

- A site-specific, in situ mechanical cleaning method using piezo-controlled metal tips achieves atomically clean suspended graphene membranes (both sides) over several µm² within minutes, without thermal or reactive treatments.

- Cleaning durations: ~6 min in SEM (limited by imaging refresh rate; ~1 min achievable with faster scanning) and ~11 min in TEM (limited by sequential double-tip approach).

- Mechanical thresholds: lateral cleaning force Fc ≈ 76.6 ± 11 nN; minimal normal force for cleaning ≈ 50 nN; operational normal forces up to ~1.6 µN; rupture threshold ~7.5 µN for the used tips.

- Adhesion energy between contamination and graphene estimated as Ea ≈ 0.36 ± 0.05 J/m², matching graphite cleavage and organic desorption energies; frictional contribution <1 nN.

- For interconnected contamination, higher forces are needed; a general relationship of ~6.7 µm⁻² (MPa) was observed for removing arbitrarily sized contamination, close to graphite interlayer shear strength.

- Success rate >80% on freshly prepared membranes; Raman spectra show no increase in D-band and no band shifts, indicating no added defects; HRTEM confirms pristine lattice with only intrinsic defects.

- EELS: oxygen K-edge present in as-prepared samples disappears after cleaning; plasmon loss peak shifts from ~22 eV (PMMA-like) to ~16 eV (graphene-like), improving C K-edge fine structure.

- Recontamination: Ex situ air exposure (5 min) largely repopulates surfaces; under vacuum, higher vacuum (TEM ~10⁻⁷ mbar) breaks up films more than SEM (~10⁻⁵ mbar) but does not eliminate contaminants.

- In situ beam-induced recontamination manifests as nm-scale amorphous seeds that grow and coalesce; growth rate depends on scan parameters. Fast scanning leads to edge-localized buildup, evidencing surface diffusion as the dominant precursor supply mechanism over gas-phase diffusion.

- Estimated surface diffusion coefficient of mobile species on graphene: D ≈ 4.88×10⁻12 m² s⁻¹ (slower than benzene/n-alkanes), indicating larger, less mobile hydrocarbons.

- Using CuTPP as a precursor supplied by surface diffusion, electron-beam exposure converts diffusing molecules to a nanocrystalline, turbostratically disordered second graphene layer within ~6 min; grains are a few nm with expected 5–7 and 5–5–8 dislocation-based grain boundaries; a third layer can initiate thereafter.

Discussion

The mechanical cleaning approach directly addresses the challenge of achieving atomically clean, site-specific regions on suspended graphene, overcoming limitations of thermal or chemical methods that lack spatial control or are incompatible with sensitive samples. Quantitative force measurements show that cleaning operates well within graphene’s mechanical limits and is governed by adhesion energies consistent with known graphene/graphite interfacial energetics. Post-cleaning Raman and HRTEM confirm preservation of lattice integrity.

The analysis of recontamination mechanisms reframes what is considered 'clean' in high vacuum: although no stationary adsorbates are visible, a dynamic population of mobile molecules persists and can be immobilized by the electron beam, leading to contamination growth. The dependence of recontamination patterns on scan speed, and the edge-localized buildup under fast scanning, demonstrate that surface diffusion, not gas-phase transport, primarily supplies precursors. The extracted diffusion coefficient suggests the mobile species are larger hydrocarbons (e.g., PMMA fragments and airborne hydrocarbons), aligning with EELS evidence and transfer-process residues. Recognizing surface diffusion as the main recontamination pathway enables experimental strategies (scan protocols, vacuum management, preconditioning) to mitigate contamination during imaging/analysis.

Furthermore, exploiting surface diffusion to deliver a defined molecular precursor (CuTPP) into a cleaned window enables controlled, beam-assisted synthesis of a nanocrystalline graphene overlayer with expected grain-boundary topologies. This demonstrates a route to site-selective nanoscale synthesis and patterning directly observed in HRTEM, extending the utility of mechanically cleaned 2D materials for in situ fabrication and study of structure–property relationships.

Conclusion

This work introduces an in situ, site-specific mechanical cleaning technique that reliably produces atomically clean suspended graphene membranes without thermal or reactive treatments, validated by Raman, HRTEM, and EELS. Quantitative force measurements establish operating windows and reveal adhesion-dominated mechanics consistent with graphene/graphite energetics. The study clarifies recontamination mechanisms in electron microscopes, identifying surface diffusion of mobile hydrocarbon species as the dominant precursor supply for beam-induced contamination, and quantifies their surface diffusivity. Leveraging this understanding, the authors demonstrate targeted, beam-assisted growth of a nanocrystalline second graphene layer from a supplied porphyrin precursor via surface diffusion.

Future research directions include: applying mechanical cleaning to a broader range of 2D materials and heterostructures; optimizing tip design and automation for faster, larger-area cleaning; engineering vacuum and scan protocols to suppress surface-diffusion-driven recontamination; identifying and controlling the chemical nature of mobile species; and expanding beam-assisted, precursor-driven in situ synthesis to tailor 2D architectures with controlled grain size, orientation, and doping.

Limitations

- Recontamination occurs rapidly upon air exposure and persists in vacuum as mobile molecules, challenging long-term cleanliness; maintaining pristine conditions requires careful vacuum and scan management.

- Mechanical cleaning success, while >80%, is not universal; membranes with pre-existing defects have reduced yield strength and can rupture under load. Interconnected or beam-cross-linked contamination requires higher forces.

- Larger rigid debris may be pushed to edges rather than removed entirely.

- TEM implementation is constrained by holder geometry (3 mm half-grid) and sequential access to both sides; SEM cleaning speed was limited by imaging refresh rate in reported experiments.

- The exact chemical identity of mobile contaminants is not fully resolved; diffusion coefficient estimates indicate larger hydrocarbons but specific species were not conclusively identified.

- During in situ synthesis, the detailed reaction pathway and the role of Cu in CuTPP remain unclear; incorporation of heteroatoms (e.g., nitrogen) into the lattice was not determined.

Related Publications

Explore these studies to deepen your understanding of the subject.