Engineering and Technology

Internal pipe corrosion assessment method in water distribution system using ultrasound and convolutional neural networks

Y. Sung, H. Jeon, et al.

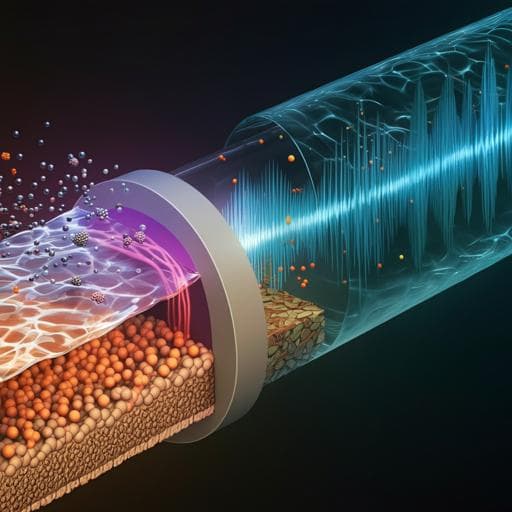

Internal pipe corrosion in drinking water distribution systems, especially in widely used cast iron pipes, produces iron oxide/oxyhydroxide scales that release iron into water (red water) and provide niches for harmful bacteria, posing health risks. Maintaining pipeline integrity and water quality requires continuous, non-destructive monitoring because corrosion causes wall thinning, pitting, leaks/bursts, hydraulic issues, and contamination. Conventional approaches (water chemistry analysis, coupon testing, internal visual inspection) are destructive or require downtime; inline corrosion monitors also need system interruption. Non-destructive testing (NDT) methods such as magnetic flux leakage (MFL) and eddy current (EC) are common but have limitations in quantifying defect size, sensitivity to lift-off, and material property confounds. Ultrasound-based NDT allows non-invasive, continuous measurement with higher resolution at higher frequencies. Scanning acoustic microscopy (SAM) uses a single high-frequency transducer to scan and form B-/C-scan images with micrometer-scale resolution. Prior work showed CNNs can infer physical properties from acoustic reflections of single cells, suggesting CNNs may also infer iron oxide particle concentrations in flowing water from ultrasound reflection signals. This study proposes a dual-mode system integrating SAM and CNN to (i) measure pipe wall thickness (corrosion) via high-frequency B-scans and (ii) classify iron oxide particle concentration in water via A-scan-based CNN analysis.

- Conventional corrosion assessment includes water chemistry, coupon testing, and visual inspections, which are destructive or require downtime. Inline corrosivity monitors also need system interruption, limiting practicality.

- NDT methods: MFL is efficient and reliable for ferromagnetic materials but requires robust defect quantification; EC works for conductive materials but is highly sensitive to lift-off and permeability effects can dominate responses.

- Ultrasound NDT is widely used; array transducers enable easy B-scans but are difficult to manufacture at very high frequencies (>15 MHz). SAM overcomes this by using a single high-frequency transducer, enabling resolutions down to ~7 μm at >200 MHz and is applied in materials and component inspection.

- Prior related works have used ultrasound with machine learning/CNNs for classifying cells and suspensions, indicating feasibility of extracting physical properties from acoustic reflections. However, obtaining internal pipe iron oxide information with NDT had not been addressed previously, motivating the present SAM+CNN approach.

System and hardware: A syringe pump (NE-4000) established steady flow (0.3 m/s) of water with Fe2O3 particles through the test pipe. A scanning acoustic microscopy system (Ohlabs Table SAM V2) acquired both B-scan images for thickness and A-scan signals for CNN classification. SAM settings: sampling rate 250 MS/s, gain 20 dB, PRF 200 Hz. Transducers: 20 MHz (V316-SU) for thickness B-scans; 5 MHz (V307-SU) for A-scan collection. Transducer performance: 5 MHz, Vpp 3.0 V, center 5.4 MHz, bandwidth 37.6%; 20 MHz, ~1.6 Vpp, center 19.0 MHz, −6 dB fractional bandwidth 110.3%.

Specimens and corrosion preparation: Brass pipes with thicknesses 477–958 μm were used as water distribution models. Accelerated corrosion was induced by immersion in 1 M nitric acid and heating at 60 °C for 24 h. Three pipes (958, 531, 528 μm) were also corroded to evaluate measurable reductions. Thickness reference measurements used a digimatic indicator (Mitutoyo ID-C150XB, 1 μm resolution).

FEA for corrosion-induced stress: Axisymmetric finite element analysis (ANSYS) modeled hoop stress changes with wall thinning. The pipe wall was meshed with five through-thickness element layers. Two cases under 300 psi internal pressure were evaluated for an OD 6.625 in pipe with wall thicknesses 0.28 in and 0.14 in.

Ultrasound data acquisition for CNNs: A-mode reflection signals were collected within pipes containing Fe2O3 particles (median size 10 μm). Six concentration classes: 1, 5, 15, 20, 100, 300 mg/L (1–15 mg/L reflect small differences relevant to water quality standards; higher concentrations extend range). For each class, 10,000 signals were acquired (total 60,000).

Signal preprocessing and input representation: Short-time Fourier transform (STFT) converted time-domain A-scans to spectrograms to capture time-frequency features. STFT parameters: window size 32, hop length 4, frequency resolution 1024. The spectrograms (approx. 1024×250×1) were used as CNN inputs.

CNN architectures and training: Four backbones were implemented with batch normalization and dropout after conv layers to mitigate overfitting.

- VGGNet: 3×3 conv filters, 2×2 max pooling; architecture with one initial conv, three VGG modules, another conv, interleaved pooling, and four fully connected (FC) layers.

- InceptionNet: stacks of 3×3 conv + pooling top layers followed by sequences of 1×1 and 3×3 conv; eleven inception modules of varying kernel combinations (including 1×1, 3×3, 5×5, and 7×7) arranged serially without branching subtasks.

- ResNet: eight residual blocks (each two 3×3 conv layers plus residual connection) with stride 2 and 2×2 pooling to expand receptive fields for high-resolution spectrograms.

- EfficientNet: fourteen MBConv blocks with depthwise conv (3×3 or 5×5), inverted residuals, squeeze-and-excitation, and channel scaling to balance depth/width/resolution. All models used Adam optimizer, ReLU activations (Softmax at output), and minimized cross-entropy loss for six-class classification.

Evaluation protocol: Five-fold cross-validation on the full 60,000-signal dataset, preserving class distributions. Metrics: accuracy, precision, recall, F1-score, computed per fold and averaged with standard deviations.

Thickness measurement via SAM: B-scan imaging with the 20 MHz transducer measured wall thickness. Results were compared to DI references to quantify measurement error and assess sensitivity to small corrosion changes (tens of micrometers).

- Finite element analysis: Halving wall thickness from 0.28 in to 0.14 in under 300 psi increased von Mises stress from 22.53 MPa to 44.25 MPa (~96% increase), confirming the inverse relation between wall thickness and hoop stress and the risk escalation with corrosion.

- Thickness measurement accuracy: For six brass pipes (thicknesses 958, 889, 784, 683, 531, 477 μm), SAM vs DI showed errors ~7–48 μm, all within 10%. For three pipes intentionally corroded, thickness reductions were 76, 69, and 80 μm; SAM vs DI differences were 2–36 μm, demonstrating micrometer-scale sensitivity to corrosion.

- CNN-based concentration classification (six classes: 1, 5, 15, 20, 100, 300 mg/L; 10,000 signals/class, five-fold CV): • ResNet: Avg accuracy 0.9972, precision 0.9983, recall 0.9972, F1 0.9969; SDs ≤ ~0.006, with near-perfect confusion matrices in most folds. • VGGNet: Avg accuracy 0.9735, precision 0.9724, recall 0.9716, F1 0.9668; SD ~0.03–0.035. • EfficientNet: Avg accuracy 0.9716, precision 0.9724, recall 0.9716, F1 0.9668; SD ~0.031–0.035. • InceptionNet: Avg accuracy 0.9423, precision 0.9392, recall 0.9423, F1 0.9285; SD ~0.022–0.030.

- Model behavior insights: Depth and large receptive fields are critical for capturing correlations among distant time-frequency components in spectrograms; multi-scale inception-style analysis was less effective for low concentration classes. VGGNet exhibited relative robustness to noisy outliers and low concentrations compared to EfficientNet. All models showed lower performance at low concentrations (e.g., 1–15 mg/L) due to less distinctive acoustic features, though ResNet largely overcame this limitation.

The dual-mode SAM-CNN framework directly addresses the need for continuous, non-destructive assessment of both pipe structural integrity and water quality. High-frequency SAM B-scans provide precise wall thickness measurements at micrometer resolution, enabling detection of small corrosion-induced changes. Concurrently, CNN analysis of A-scan-derived spectrograms accurately classifies iron oxide particle concentrations, including small differences relevant to water standards (1, 5, 15 mg/L). The strong performance of deep ResNet models highlights the importance of large receptive fields to interpret time-frequency correlations tied to particle concentrations, while VGGNet’s simpler architecture demonstrated robustness to low-concentration indistinctiveness and outliers. The inferior performance of multi-scale InceptionNet suggests that straightforward depth and receptive field expansion are more important than multi-kernel scale mixing for this task. These findings validate that acoustic reflection signals contain discriminative signatures of particle concentration and that high-frequency ultrasound imaging can quantify corrosion non-invasively. The approach supports real-time monitoring and can be integrated with analytical thin/thick-walled equations or FEA for stress estimation, enabling predictive maintenance through time-series forecasting methods (e.g., ARIMA, LSTM, CNN) to anticipate failure while considering safety factors.

This work demonstrates a practical, precise, and non-destructive dual-mode system that integrates high-frequency SAM with CNNs to: (i) measure pipe wall thickness for corrosion assessment with micrometer accuracy, and (ii) classify iron oxide particle concentrations in flowing water with high accuracy (up to ~99.7% with ResNet). The study provides architectural insights indicating that sufficient network depth and receptive field size are key to extracting particle concentration features from acoustic spectrograms, and that simpler architectures can aid robustness at low concentrations. The validated SAM-CNN hybrid system paves the way for continuous in situ monitoring of water distribution pipelines, supporting real-time integrity and water quality assessment and enabling predictive maintenance through coupling with stress models and time-series prediction. Future research should include extensive validation in real cast iron infrastructures, broader contaminant and particle type assessments, on-line deployment under varied hydraulic and environmental conditions, and domain adaptation to handle field variability.

The study relied on brass pipes and accelerated corrosion protocols due to the difficulty and time required to generate realistic corrosion in operational water supply pipes. Although brass and cast iron share similar acoustic properties (impedance, speed of sound, density), field validation on cast iron is needed. Creating controlled, real-world corroded samples remains challenging, and laboratory conditions (flow, temperature, particle distributions) may not fully represent distribution system variability.

Related Publications

Explore these studies to deepen your understanding of the subject.