Earth Sciences

In situ observation of glass-like fragmentation of high-temperature silicate melts generating fine ashes

A. Namiki, S. Okumura, et al.

Explosive volcanic eruptions disperse ash that affects the environment and society; ash size, shape, and distribution control atmospheric residence and dispersal. Fragmented magmas produce particles with diverse sizes and morphologies, with some ashes preserving pre-fragmentation bubbles and others being bubble-free. Dense, fine ashes are common in ash explosions after Strombolian and in Vulcanian eruptions. Magma, though a viscous fluid, can fragment in a brittle manner when deformation is rapid relative to the viscoelastic relaxation time, commonly expressed by the Deborah number (De = γ τr with τr = η0/G∞). Prior elongation experiments suggested thresholds around De ~ 0.01–0.04 for brittle fragmentation, even though De ~ 0.01 is nominally in a viscous regime. Shock-tube decompression of bubbly magma indicates brittle fragmentation when ΔP φ exceeds a critical value, and fragment size decreases with increasing ΔP φ, implicating pressurized pre-existing bubbles. Whether dense, bubble-poor ashes typical of certain low-intensity eruptions can be produced by such bubble-driven mechanisms remains unclear. Meanwhile, materials science shows that glass fracturing below Tg exhibits mixed elastic and dissipative processes near crack tips, including cavitation and crack branching, yielding characteristic mirror–mist–hackle surface morphologies. It is unknown whether these glass-like fracture processes occur in high-temperature silicate melts. This study performs in situ high-temperature tensile experiments on rod-shaped soda glass and haploandesite melts to observe fracture development, quantify rheology from stress–strain curves, and relate deformation regime to fragmentation and fragment generation.

Prior work establishes that magma fragmentation depends on deformation rate relative to viscoelastic relaxation (De = γ η0/G∞). Extensional tests identified a brittle-fragmentation threshold at De > ~0.01–0.04, applied to crystal-bearing magmas and conduit models. Rapid decompression of bubbly magmas shows brittle fragmentation when ΔP φ exceeds a threshold; finer fragments occur at larger ΔP φ, stressing the role of gas overpressure in bubbles. However, dense ashes from Strombolian ash explosions and Vulcanian eruptions challenge purely bubble-driven fragmentation. In glasses at room temperature, fracture surfaces exhibit mirror–mist–hackle morphologies; mirror size scales as σ−1/2, and crack propagation involves stress corrosion and nanocavity nucleation/coalescence akin to ductile fracture in metals. Dynamic fracture studies reveal cavitation, nonlinearity, and branching instabilities at high crack speeds. These insights suggest that void nucleation and branching may govern fragmentation and roughness, but their applicability to high-temperature silicate melts had not been directly tested.

High-temperature tensile fragmentation experiments were conducted on rod-shaped silicate samples using a vertical tensile testing apparatus (AND MCT-1150) within an annular furnace. Rod samples were attached via spheres to Inconel pistons; the upper piston applied constant-velocity extension at prescribed strain rates. Force (Kyowa LUX-B-200N-ID, 14 kHz eigenfrequency) and displacement (Keyence LK-G155A, response time 100–1000 µs) were recorded to compute engineering strain x/L and stress F/[π(w/2)^2], with L and diameter w measured at the onset of each run. Deformation and fracture were imaged in situ by a high-speed camera (Photron FASTCAM SA-Z) through furnace ports configured for front lighting and black back background to enhance contrast. Alignment was carefully adjusted by reorienting a piston slit to minimize off-axis loading; fractures near grips were flagged as potential misalignment effects. Post-mortem fracture surfaces were characterized by SEM (JEOL JSM-7001F) and laser confocal microscopy (Olympus LEXT OLS4000) to quantify smooth and rough regions and topography. Samples: soda glass and transparent, Fe-free haploandesite (andesite analog) prepared by melting (soda glass ~1200 °C; haploandesite 1500 °C), bubble removal by extended hold (up to 40 h), fibre pulling with a quartz rod, cutting, and adding end spheres; samples were cooled without annealing. Experiments varied sample temperature, strain rate, and preheating history. For soda glass, operating temperatures ~600–660 °C with preheating ≤820 °C; for haploandesite, 880 °C without preheating (unless noted). Representative conditions (Table 1) included strain rates from ~0.0036 to 0.027 s−1 for soda glass and 0.0055 to 0.053 s−1 for haploandesite; sample diameters ~0.56–0.80 mm and lengths ~22–35 mm. In some runs, preheating or prior elongation produced locally thinner sections; associated stress estimates could carry up to ~40% error due to cross-sectional variation. Rheological parameters (elongation viscosity ηelong assumed 3× shear viscosity η, and Young’s modulus E) were inferred by fitting measured stress–strain curves to an extensional Maxwell model under constant strain rate: σ(t) = 3ηγ̇[1 − exp(−t/τ)], with τ = 3η/E and assuming ν≈0.5 (E≈3G); effects of ν≈0.25 were considered. Relaxation time was estimated by two approaches: (1) τ = 3η0/E∞ using zero-strain-rate viscosity and infinite-rate modulus (yielding τ ≈ 1.3 s for soda glass, τ ≈ 0.31 s for haploandesite), and (2) a strain-rate–dependent estimate τe based on the onset of shear thinning and modulus asymptote, informed by Cox–Merz-type analogies; differences between τ and τe help rationalize fragmentation thresholds. Data quality considerations included potential furnace port cooling leading to sample temperatures a few to ~>10 °C lower than set points at high T, confirmed by prior calibration.

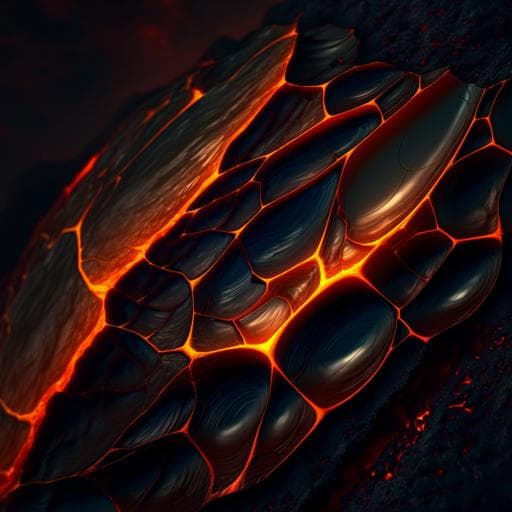

- In situ high-speed imaging shows that at high temperature both soda glass (600–660 °C) and haploandesite melts (880 °C) fracture by rapid crack propagation without necking, consistent with brittle-like failure; crack traverses the 0.6–0.8 mm rods within ≤10−5 s (propagation time <10−6 s estimated from E ~20 GPa and ρ ~2500 kg m−3).

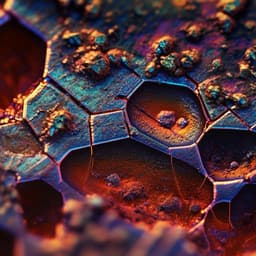

- Fracture surfaces consistently exhibit dichotomous smooth and rough regions analogous to room-temperature glass (mirror–mist–hackle). Rough regions, often lower in topography relative to smooth zones, are the source of secondary small fragments; roughness wavelengths increase with distance from smooth areas and include micrometer-scale textures at the boundary.

- Fragment size decreases as strain rate increases; at γ = 0.027–0.053 s−1 finer fragments are observed compared with γ ~0.0036–0.0044 s−1.

- A preheating condition that created a locally thinner section (preheat 820 °C; test at 650 °C, γ = 0.0044 s−1) produced smooth fracture surfaces with no notable small fragments, and fluctuating stress–strain curves prior to failure, indicating that local thinning reduces required force and affects fracture mode.

- Haploandesite at 880 °C shows similar smooth–rough fracture surface morphology; small crescent-shaped fragments originate from rough regions. At slower strain rates (γ ≈ 0.027 s−1), viscous shape deviations at rims coexist with fracture; at faster rates (γ ≈ 0.053 s−1), surfaces show less clear smooth–rough differentiation and finer fragments.

- Stress–strain analysis: In most experiments, stress initially rises (elastic response) and then plateaus toward 3ηγ (viscous regime); fragmentation typically occurs after the onset of viscous deformation, evidenced by σmax/(3ηγ) ≈ 1 across fragmented and non-fragmented cases, largely independent of normalized strain rate τeγ. Measured peak stresses are on the order of 10^8 Pa.

- Deviations (σmax/(3ηγ) < 1) are mainly in colder glass (≤615 °C) at rapid τeγ > 0.01 and in cases with strong preheating-induced geometry effects, where rheological estimates are less constrained.

- Fragmentation thresholds are not governed solely by strain rate, stress, or strain; samples under similar early stress–strain evolution sometimes fragment and sometimes do not. Critical strain for fragmentation depends on material: haploandesite requires larger strain than soda glass.

- Compositional structure (NBO/T): more polymerized haploandesite (lower NBO/T) withstands larger strains before fragmentation; less polymerized soda glass (higher NBO/T) likely forms subnanometre chemical heterogeneities (e.g., Na/Ca/Fe clusters) that act as void nucleation sites at smaller strains, shortening the path to fragmentation.

- Comparison with prior De-based thresholds indicates that fragmentation can occur in regimes previously considered viscous (γ < 0.01/τ), likely due to extensional geometry efficiently nucleating voids that drive crack initiation and branching.

- Normalized analysis shows fragmentation occurrence aligns with the viscous stress scale 3ηγ, suggesting viscous deformation promotes conditions for crack nucleation and branching that generate dense fine ash-like fragments.

The experiments directly demonstrate that high-temperature silicate melts can undergo glass-like fracture characterized by smooth and rough surface zones, with rough regions generating small fragments via crack branching. Although visually brittle (no necking), stress–strain curves show that fragmentation typically occurs after viscous deformation begins (σmax ≈ 3ηγ), indicating that viscous flow locally around crack tips enables ductile processes such as void nucleation and coalescence that destabilize cracks and cause branching. This reconciles the apparent contradiction between viscous deformation regimes and brittle-like fragmentation, and explains how dense, fine ash can be produced without relying on pre-existing pressurized bubbles. The findings challenge the universality of simple Deborah-number thresholds for fragmentation; in extensional geometries, void nucleation is efficient, and fragmentation can occur for γ below classical 0.01/τ. Material dependence—through network polymerization (NBO/T)—modulates the critical strain, with more polymerized melts sustaining larger strains prior to fragmentation. Extrapolating to natural magmas, abundant flaws (bubbles, crystals, volatile heterogeneities) would provide multiple crack nucleation sites; under high stress or rapid strain, numerous cracks initiate and branch, generating finer fragments than the initial flaw spacing. Under lower stress with higher vesicularity, viscous deformation thins melt films and realigns heterogeneities, lowering the stress required for fracture and facilitating fragmentation into pumice/scoria and less frequent branching. Thus, the mechanism of fine dense ash production in ash-rich Vulcanian and post-Strombolian explosions can be explained by branching cracks in viscously deforming, relatively low-vesicularity melts, with fragment size inversely related to applied stress as in glass fracture (narrower mirror regions at higher stress).

This study provides in situ evidence that high-temperature silicate melts fragment via glass-like mechanisms: tensile deformation initiates cracks that, aided by ductile processes around crack tips, branch and generate small fragments from rough fracture regions. Fragmentation commonly occurs after the onset of viscous deformation (σmax ≈ 3ηγ) and is not uniquely controlled by strain rate; material structure (polymerization/NBO-T) influences the critical strain. These insights offer a unifying explanation for the generation of fine, dense volcanic ash in low-intensity eruptions without invoking solely bubble overpressure, and call for incorporating extensional, void-nucleation-driven fragmentation into eruption models. Future work should quantify branching dynamics versus stress, extend experiments to volatile-bearing, crystal- and bubble-laden natural compositions, refine temperature control and geometry effects, and link fracture-surface metrics to fragment size distributions to better parameterize ash production in models.

- Temperature control: visualization ports in the furnace can reduce the actual sample temperature below set points by several to >10 °C at high operating temperatures, introducing uncertainty in viscosity and modulus estimates.

- Geometry-induced uncertainty: preheating that created locally thinner sections led to up to ~20% diameter variation and potential ~40% stress-estimation error; strain concentration and radial strain components are not captured by the simple Maxwell model used for fitting.

- Alignment: despite careful alignment, residual misalignment may introduce non-tensile stresses; fractures near grips were noted and may reflect stress concentrations at joints.

- Rheology estimation: viscosity and modulus were inferred from finite-strain extensional tests assuming ηelong = 3η and ν≈0.5; deviations in Poisson’s ratio and non-Maxwell behavior at low temperatures or with geometric nonuniformity limit parameter accuracy. Relaxation times τ and τe differ by orders of magnitude, complicating De-based thresholds.

- Sample representativeness: haploandesite is Fe-free and bubble/crystal free to ensure transparency and avoid crystallization; natural magmas contain crystals, bubbles, and volatiles that act as flaws and alter rheology and fracture behavior.

- Optical limitations: transparent samples in a bright furnace are challenging to image; frame rate and resolution limit direct observation of sub-microsecond crack tip processes and micrometre-scale roughness formation dynamics.

Related Publications

Explore these studies to deepen your understanding of the subject.