Engineering and Technology

Impact of solid-electrolyte interphase reformation on capacity loss in silicon-based lithium-ion batteries

T. Vorauer, J. Schöggl, et al.

Silicon-based anodes promise high energy density due to their high theoretical specific capacity, low cost, and abundance, but suffer from up to ~300% volume expansion/contraction during cycling, causing rapid capacity fade and limited lifetime. A key process is the formation and reformation of the solid electrolyte interphase (SEI) at the silicon surface, which is strongly influenced by electrode architecture, electrolyte composition, cycling protocol (e.g., C-rate), and especially by cell configuration (half-cell vs full-cell). Conventional Si composite anodes feature Si domains (amorphous Si with FeSi2 inclusions) embedded in a porous carbon binder domain (CBD) and graphite matrix; ionic transport is governed by the pore network while electronic transport relies on conductive additives and binder. Repeated lithiation/delithiation induces cracking, loss of electrical contact, and progressive SEI evolution, but the structural and chemical progression of SEI reformation in industrially relevant full cells across multiple length scales remains insufficiently understood. This study aims to clarify how SEI reformation into a thicker silicon-electrolyte composite (SEC) around Si domains evolves with cycling in a full-cell configuration, and how this affects active material utilisation and capacity retention.

Prior studies have shown SEI formation on Si comprises F, O, C, and P and initially forms ~20 nm layers; volume changes induce cracking and SEI growth on newly exposed surfaces, potentially degrading nanostructures such as Si nanowires. SEI and performance are sensitive to C-rate. Cell configuration critically affects Si activation and SEI evolution; half-cells and full cells can yield different structural and chemical outcomes. Structural changes at different particle sizes and pore clogging linked to SEI growth have been observed, but correlative proof in full cells spanning micro- to nanoscale with chemical specificity has been limited. Imaging methods including micro-X-ray computed tomography (µ-XCT)/X-ray microscopy (XRM) and FIB-FESEM tomography with EDS and ToF-SIMS have been applied to battery electrodes, but comprehensive, correlated, multi-scale, multi-modal workflows for industrially relevant full cells remain scarce. This work builds on these advances by integrating XRM, FIB-FESEM tomography, EDS, ToF-SIMS, and deep-learning segmentation to resolve structural/chemical evolution and links it to electrochemical and chemo-mechanical modelling.

Electrodes and full-cell configuration: The anode is a technology-relevant Si-nanocomposite consisting of amorphous Si (a-Si) and crystalline FeSi2 (c-FeSi2) domains embedded in porous carbon binder domain (CBD) and graphite. Negative electrode composition (wt%): 50% Si-based active material (3M L20772; active contains ~20% graphite, 25% a-Si, 55% c-FeSi2 by weight), 41% graphite (BTR918), 2% carbon black (Super P), 7% lithium polyacrylate (LIPAA) binder (PAA MW 450,000). Area capacity ~2.40 mAh cm−2 (as reported). Full pouch cells employ Celgard 2400 separator and electrolyte of 1 M LiPF6 in 3FEC/7EMC (v/v) with 2 wt% VC; cathode is NMC (1/1/1) with 2.0 mAh cm−2 loading; Al (cathode) and Cu (anode) current collectors. Electrochemical cycling: Maccor 4000 tester. Cycling at 0.5 C; rate capability checks at cycle 25 and every 100 cycles (C/10, C/5, C/2, 2 C). Capacity retention after 300 cycles at C/2 ~70%. Correlated multi-scale imaging workflow: XRM used first to select representative volumes of interest (VOIs) for subsequent nanoscale analysis. XRM (Zeiss Xradia 620 Versa): 60 kV, 108 µA, LE1 filter, 40° objective with optical magnification, 220 nm voxel, 360° rotation, 3001 projections, 23 s exposure. Volume ~400 × 31 × 417 µm3. XRM-FIB/SEM correlation achieved via surface tracking marks and ZEISS Atlas 5/3D packages. FIB-FESEM tomography: Zeiss Crossbeam; voxel 12 × 12 × 12 nm3 (imaging at 2.0 kV, 1.0 nA; FIB 30 kV/3 nA). Sample preparation included ~20 nm Ir sputter coat, Pt deposition and FIB shaping for planarity. 3D-EDS mapping: 5 kV, 4 nA, voxel ~50 × 50 × 250 nm3 with slices every 250 nm; elements mapped include C, Si, O, Fe (selected 2D examples). Acquisition per slice ~1.5 min; total 3D imaging + EDS times ~23–29 h depending on sample. ToF-SIMS: TOFWERK C-TOF connected to FIB-FESEM; overview 20 × 20 µm2 at 10 kV/10 pA; final 7 × 7 µm2 at 30 kV/10 pA; 1024 × 1024 pixels, 12.8 µs dwell, 4×4 binning. Corrected for 54° acquisition angle in post-processing. Sensitive to 7Li, 6Li, 16O, 19F. Noise thresholding (>10% of max intensity) applied to EDS and ToF-SIMS maps. Deep learning segmentation: Convolutional neural network (U-Net architecture; Python segmentation models) trained on labelled FIB-FESEM images (Ilastik; labels guided by EDS). Training on Nvidia GPUs (1000 epochs total). Images normalised to first significant local maximum and by standard deviation; resized to 1248 × 1952 px. Four-phase segmentation: Si/FeSi2, graphite, pores, CBD (pristine) or CBD+SEC (cycled). Accuracy ~90%. Comparable sub-volumes (7 × 7 × 7 µm3) chosen ensuring graphite 30–40 vol% for statistical consistency across states. SEC vs CBD discrimination: Combined CNN prediction with EDS and ToF-SIMS via logical operations to identify SEC pixels (intersection or union as defined) and CBD (symmetric difference), enabling estimation of SEC fraction within CBD+SEC for 3 and 300 cycles. Chemo-mechanical modelling: Continuum solid mechanics framework using chemical affinity tensor to model stress-assisted SEI growth into Si as a localised chemical reaction across a moving interface (reaction front). Linear elastic Si and SEI phases with Young’s moduli E1 (Si) and E2 (SEI); stability analysis of planar front as function of moduli ratio E1/E2, chemical energy parameter γ, and transformation strain θ. Kinetics simulated via CutFEM extended to large-deformation mechanochemistry. Electrochemical modelling: Physics-based 2D microstructure-resolved model (COMSOL Multiphysics v5.6, DFN-based) using segmented microstructures as geometries. Simulated in half-cell configuration (Li-metal anode, 1 M LiPF6 (EC:EMC 3:7) electrolyte; as-received microstructure as cathode domain stand-in for Si composite region). Fixed applied current −4 × 10−6 A from zero lithiation to 0.2 V cutoff. Same parameters for 3- and 300-cycle microstructures; only SEC/CBD content varied according to experimental quantification (SEC:CDB ~65:35 at 3 cycles; ~80:20 at 300 cycles). Outputs: Li+ concentration, electrolyte potential, state of lithiation distributions.

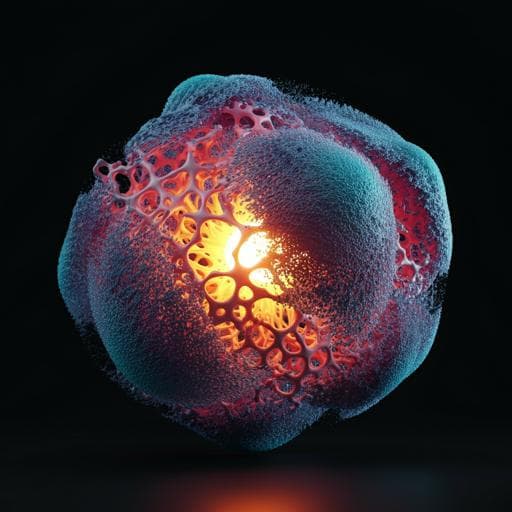

- Multi-scale correlative imaging and ML segmentation reveal that the initially nanometre SEI evolves into a micron-scale silicon-electrolyte composite (SEC) structure enveloping Si domains with cycling in a full-cell configuration.

- Deep-learning quantification shows a notable Si-core volume fraction loss of about 50% from pristine to 300 cycles; the CBD+SEC phase grows correspondingly (ML segmentation: dark-green phase increases from ~13 vol% at 3 cycles to ~24 vol% at 300 cycles within the analysed VOIs).

- SEC vs CBD discrimination using combined CNN+EDS+ToF-SIMS indicates the SEC fraction within the CBD+SEC region increases from about 65% (3 cycles) to about 80% (300 cycles).

- EDS shows increasing oxygen signal at Si interfaces with cycling; ToF-SIMS maps 7Li concentrated in regions of low Si EDS intensity around Si cores (core–shell-like structure) at both 3 and 300 cycles, indicating Li trapping in SEC.

- Averaged ToF-SIMS/EDS elemental increases from 3 to 300 cycles: 7Li +167%, 6Li +151%, 16O +546%, 19F +155% in SEC regions, consistent with electrolyte decomposition (LiPF6-derived species) and formation of LixSi, SiOx, and possibly lithium oxides within SEC.

- Even after 300 cycles, intact Si cores remain, indicating underutilised interior active material due to SEC growth and transport limitations.

- Electrochemical modelling (using experimentally segmented microstructures) shows strong Li+ depletion within SEC and proximate domains at end of discharge (Li+ as low as ~1e−19 mol m−3 in inner SEC vs ~1e−3 mol m−3 in proximate regions), heterogeneous electrolyte potentials, and poor lithiation of inner Si particles (<5%) vs outer reaching ~10%.

- Histogram of state of lithiation: maximum ~30% (3 cycles) vs ~24% (300 cycles); median 7.4% vs 5.1%, respectively; difference ~2.3% indicates further reduced utilisation with SEC growth.

- Simulated discharge potential profiles regress earlier for 300 cycles at lower potentials (~0.4 V), consistent with increased SEI/SEC hindering active surface area.

- Chemo-mechanical stability analysis shows the planar Si/SEI reaction front stability depends on Young’s modulus ratio E1/E2; qualitative change in stability regions when E1/E2 crosses ~1; unstable fronts promote interface waviness/heterogeneities consistent with observed SEC morphology.

- Full-cell cycling performance shows ~70% capacity retention at C/2 after 300 cycles; structural analyses link capacity loss to SEC growth, Si redistribution from core to vicinity, and Li trapping.

The study addresses how SEI reformation in full cells affects Si-based anode capacity by directly correlating 3D structure and chemistry across scales and by modelling transport and mechanics. The results show that repeated SEI reformation produces a thicker, heterogeneous SEC around Si domains. This growth consumes Si from the core vicinity (evidenced by ~50% Si-core volume loss and reduced grey-value separation), accumulates electrolyte-derived species (O, F), and traps Li in the SEC (ToF-SIMS 7Li), forming a core–shell configuration that impedes Li+ transport to interior Si. Electrochemical simulations on measured microstructures confirm severe Li+ depletion within SEC regions and reduced lithiation of inner Si particles, explaining underutilisation of active material and the observed capacity fade. The chemo-mechanical model indicates that interfacial stability is governed by elastic property mismatch and transformation strain/chemical driving force; unstable fronts can amplify local stress/geometry perturbations (e.g., pores/cracks), fostering heterogeneous SEC growth and further transport hindrance. Together, these findings connect SEC reformation and growth to transport limitations, Li trapping, and mechanical instabilities that collectively reduce capacity in industrially relevant full-cell configurations, distinct from graphite anodes and from half-cell behaviours.

This work establishes a correlative, multi-scale, multi-modal workflow, enhanced by deep learning segmentation, to resolve the structural and chemical evolution of Si anodes in full cells. It reveals that the SEI evolves into a micron-scale SEC that grows with cycling, redistributes Si from the core to the interface, traps Li, and increasingly obstructs ionic access to interior Si. Quantitatively, Si-core volume declines by ~50% and SEC fraction within CBD+SEC increases from ~65% to ~80% between 3 and 300 cycles; oxygen and fluorine from electrolyte decomposition accumulate; modelling shows severe Li+ depletion in SEC and reduced lithiation of inner Si, aligning with ~70% capacity retention at C/2 after 300 cycles. Chemo-mechanical analysis implicates elastic modulus ratios and transformation strain in front stability, offering a mechanistic explanation for heterogeneous SEC morphologies. Future research should focus on material and architectural designs that stabilise SEI formation and minimise reformation (e.g., Si-alloys/compounds, tailored binders/additives), engineer interfacial mechanical properties (e.g., modulus matching, graded layers), and optimise pore/electrode architectures to sustain ionic pathways and limit SEC growth. Extending modelling to include trapped Li in SEC, full-cell conditions, and dynamic chemistries will further guide practical design.

- Imaging resolution and contrast: Single nm-scale SEI layers cannot be resolved by FIB-FESEM; CBD vs SEC cannot be distinguished by FESEM grey values alone, requiring correlative EDS/ToF-SIMS with logical inference. EDS and ToF-SIMS maps do not fully coincide due to resolution, sampling depth, and drift, introducing uncertainty.

- Quantification uncertainties: CNN segmentation has ~90% accuracy; SEC/CBD discrimination relies on set operations combining imperfect datasets; small ROIs may bias isotope count statistics.

- Modelling simplifications: Electrochemical simulations use a half-cell framework and do not account for trapped Li within SEC; identical parameters applied to 3- and 300-cycle cases except SEC/CBD ratio; real full-cell dynamics and evolving kinetics are not fully captured.

- Generalisability: Results pertain to a specific Si-graphite-CBD composite, electrolyte (LiPF6 in FEC/EMC with VC), cycling protocol, and NMC cathode; different materials or protocols may change SEC evolution.

- Potential measurement artefacts: FIB-induced modifications (e.g., redeposition, Ga, Pt) and surface preparation steps could affect local chemistry/contrast; efforts were made to identify artefacts via EDS.

Related Publications

Explore these studies to deepen your understanding of the subject.