Food Science and Technology

Impact of hydrophilic substances on Ostwald ripening in emulsions stabilized by varied hydrophilic group surfactants

J. Kim, Y. Noh, et al.

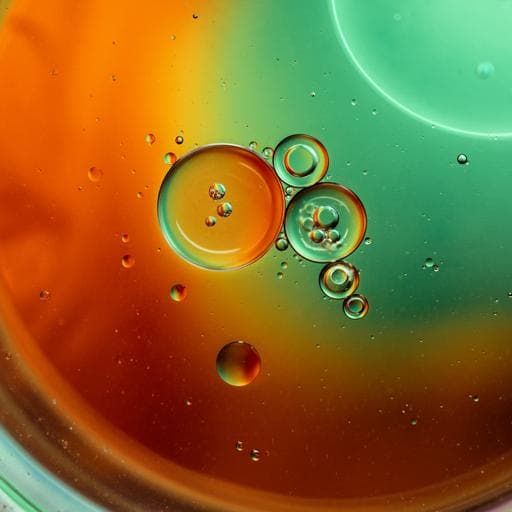

The study addresses how Ostwald ripening (OR) affects the stability of oil-in-water emulsions, which are widely used in foods and beverages and are inherently thermodynamically unstable. OR is particularly important in systems with oils of appreciable water solubility (e.g., essential oils, flavor oils, shorter-chain triglycerides) and is more rapid in nanoemulsions due to higher curvature increasing oil solubility. OR leads to droplet growth via molecular transport from smaller to larger droplets and can accelerate other destabilization mechanisms such as creaming and coalescence. The classical OR relation predicts growth increases with interfacial tension, oil solubility, and diffusion coefficient, implying emulsifiers (interfacial tension) and aqueous additives (viscosity, solubility) can modulate OR. The study aims to elucidate the effects of emulsifier head-group structure (Tween 60 vs Brij S20) and water-soluble additives (glucose, maltose, glycerol, propylene glycol) on OR in model n-decane emulsions and in mixed oil systems with corn oil as a ripening inhibitor, reflecting conditions relevant to concentrated beverage emulsions that contain high levels of hydrophilic additives.

Prior work shows OR can be mitigated by adding hydrophobic ripening inhibitors to polar oils (“compositional ripening,” CR), often triglycerides that also reduce creaming by acting as weighting agents. The OR rate for pure oils follows d(t)^3 = d(0)^3 + (64 γ Vm D S t)/(9 R T), highlighting roles of interfacial tension, solubility, and diffusion. Threshold mole fractions of inhibitor for kinetic vs thermodynamic OR suppression have been derived (X2 thresholds based on interfacial parameters and initial droplet size). Emulsifier interfacial properties and micelles can influence mass transport and OR; micelles can solubilize oil and increase OR. Additives such as polyols can alter interfacial packing, surfactant hydration, and oil solubility, potentially affecting OR. These concepts guided the present experimental design and interpretation.

Materials: Tween 60 (polyoxyethylene (20) sorbitan monostearate), Brij S20 (polyoxyethylene (20) stearyl ether), glycerol, sodium azide (Sigma-Aldrich); n-decane and propylene glycol (Daejung); glucose (Alfa Aesar); maltose monohydrate (Duksan); corn oil (local supermarket). All reagents were reagent grade. Emulsion preparation: Aqueous phases contained 0.5% (w/w) Tween 60 or Brij S20 in 10 mM phosphate buffer (pH 7) with 0.02% (w/w) sodium azide, plus 0, 5, 15, or 30% (w/v) of glucose, maltose, glycerol, or propylene glycol. Oil phases contained n-decane with 0, 5, 10, 20, or 30% (w/w) corn oil. Coarse emulsions (5% oil, 95% aqueous, w/w) were formed by high-shear blending for 2 min at 25 °C, then microfluidized (MN400BF) five passes at 100 MPa to form fine emulsions. Final pH was adjusted to 3 or 7, and samples stored at 25 °C in the dark. Droplet size: Measured during storage by laser diffraction (BT-9300ST), after dilution in matching pH buffer; refractive indices: oil 1.411, water 1.333; reported as volume-weighted mean diameter dv = Σni di^3 / Σni di^2. OR rate determination: Based on Lifshitz–Slyozov–Wagner theory, using rt^3 − r0^3 = ω t, where r0 and rt are initial and time-t radii; OR rate ω (µm^3/day) from linear regression of (rt^3 − r0^3) vs time. Relative OR rate expressed as percentage vs control without additive (or without corn oil). Viscosity: Aqueous phases measured at 25 °C using sine-wave vibro-viscometer (SV-10). Interfacial tension: Measured at 25 °C by pendant drop tensiometer (DSA 25) for n-decane or n-decane:corn oil (95:5 w/w) against emulsifier solutions; pendant drop via 1.8 mm needle; analysis with Advance 1.9.2.3 software. Statistical analysis: Experiments in triplicate; means ± SD; Duncan’s multiple range test, p < 0.05 (IBM SPSS v21).

- Compositional ripening via corn oil: Increasing corn oil fraction in the oil phase reduced OR. At ≥20% (w/w) corn oil, droplet growth was largely suppressed for n-decane emulsions independent of surfactant and pH (3 or 7). Predicted inhibitor mole fraction thresholds were X2 ≈ 0.007 (kinetic) and 0.022 (thermodynamic); experimental suppression at 20% corn oil corresponded to X2 ≈ 0.039, higher than the thermodynamic prediction. Initial droplet diameters were similar across oil compositions (Brij S20: 0.450 µm; Tween 60: 0.442 µm). - Surfactant effects without inhibitor: In the absence of corn oil, Brij S20-stabilized emulsions exhibited higher droplet growth (higher apparent OR rate) than Tween 60-stabilized emulsions, despite Brij S20 forming denser/thicker interfacial layers and lower interfacial tension. - Water-soluble additives without inhibitor (pH 3): Glucose and maltose reduced OR rates similarly; glycerol also reduced OR but less effectively; propylene glycol increased OR in Brij S20-stabilized emulsions above a certain concentration but had little effect in Tween 60-stabilized emulsions. - Mechanisms: Additives increased aqueous viscosity (glucose ≈ maltose > glycerol at equal concentration), likely reducing oil diffusion and droplet collisions. For Tween 60, interfacial tension decreased with increasing additive concentration for all three additives, potentially further reducing OR; for Brij S20, interfacial tension was little affected. - Water-soluble additives with inhibitor (95% n-decane/5% corn oil): Overall OR rates were lower than without corn oil. Glucose and maltose significantly reduced OR when raised from 0 to 5%, with little additional benefit at higher levels. Glycerol showed no significant concentration-dependent change. Propylene glycol increased OR above ~15% even with corn oil present. Interfacial tension changes were small in the presence of corn oil, suggesting viscosity and interfacial structural effects predominated. - Surfactant-dependent response: With corn oil present, Brij S20 emulsions showed lower growth rates than Tween 60, consistent with OR theory when coalescence was minimized. - pH effect: Storage pH (3 vs 7) had little impact on droplet growth due to the nonionic nature of the surfactants.

The findings demonstrate that both oil phase composition and aqueous additives regulate OR in food-grade emulsions. Corn oil acted as an effective ripening inhibitor for n-decane via compositional ripening, with experimental suppression requiring a higher inhibitor mole fraction than simple theory predicts. In the absence of inhibitor, Brij S20 systems showed faster droplet growth than Tween 60 systems, contrary to expectations from interfacial tension and presumed interfacial thickness. The authors attribute this discrepancy to coalescence superimposed on OR: rapid initial OR yields larger droplets prone to coalescence and creaming (especially in cream layers), which accelerates apparent growth and masks pure OR trends. Micelle-mediated solubilization may contribute to OR, but the observed trends suggest micelle concentration differences were not dominant. With ripening inhibitor present (smaller droplets, reduced coalescence), behavior aligned more closely with OR theory: higher interfacial tension associated with faster OR. Hydrophilic additives reduced OR mainly by increasing aqueous viscosity (lowering diffusion) and, in some cases (Tween 60), by slightly lowering interfacial tension. Differences between glucose/maltose and glycerol may also reflect distinct impacts on water structure and activity affecting hydrophobic hydration shells and possibly micellization. Propylene glycol uniquely increased OR (notably for Brij S20) by altering surfactant hydration, interfacial packing, curvature, and cosolvent-enhanced solubilization, indicating that single-chain-headgroup interfacial layers may be more susceptible to such perturbations than multi-chain headgroups. In mixed oil systems, propylene glycol still elevated OR above a critical concentration despite minimal interfacial tension changes, implying synergistic effects of corn oil and propylene glycol on interfacial structure. Overall, selecting appropriate aqueous additives and ripening inhibitors is crucial for designing emulsions with reduced OR and extended shelf life, especially for polar oil systems.

Corn oil effectively inhibits Ostwald ripening in n-decane emulsions via compositional ripening, with ≥20% (w/w) in the oil phase suppressing droplet growth across surfactant types and pH. Hydrophilic additives modulate OR in a surfactant- and concentration-dependent manner: glucose and maltose consistently reduce OR, glycerol provides a lesser reduction, and propylene glycol increases OR (notably with Brij S20) and above ~15% even when corn oil is present. Additive effects arise primarily from increased aqueous viscosity (reduced diffusion) and modest interfacial tension reductions; propylene glycol also perturbs interfacial structure and surfactant hydration. With ripening inhibitor present, coalescence is minimized and OR trends align with theory, revealing surfactant-dependent interfacial influences. These insights guide formulation of more stable emulsions and nanoemulsions for food and beverage applications using polar oils. Future work should clarify how propylene glycol and similar cosolvents modify interfacial layers for surfactants with differing head-group architectures.

Interpretation of OR rates in the absence of ripening inhibitor is confounded by concurrent coalescence and creaming, potentially masking pure OR behavior. The study used a specific model oil (n-decane) and two nonionic surfactants (Tween 60, Brij S20) at one surfactant concentration (0.5% w/w), at a fixed temperature (25 °C) and two pH values (3, 7), which may limit generalizability to other oils, emulsifiers, concentrations, or conditions. The mechanistic role of propylene glycol on interfacial layer structure remains unclear and was not directly probed beyond interfacial tension and viscosity measurements.

Related Publications

Explore these studies to deepen your understanding of the subject.