Chemistry

Host-guest charge transfer for scalable single crystal epitaxy of a metal-organic framework

A. Mantel, B. Stöger, et al.

The study addresses the challenge of growing bulk single crystals of metal-organic frameworks (MOFs), which is crucial for fundamental research and practical applications. While prior reports achieved millimeter-scale MOF crystals (e.g., MOF-5 and HKUST-1) and up to ~6–7 mm for certain systems via specialized methods, truly bulk, centimeter-scale crystals remain rare. The authors propose using DMSO as a solvent with zinc acetate and terephthalic acid (TPA) precursors—commonly used for MOF-5 in DMF/DEF—to access a distinct, charge-transfer MOF whose host-guest electrostatic interactions can drive scalable, continuous homoepitaxial growth to centimeter lengths. The purpose is to elucidate the structure and growth mechanism enabling unlimited single-crystal epitaxy.

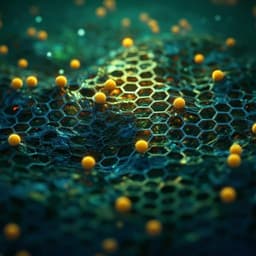

Background literature highlights the importance of MOF single-crystal growth for applications and fundamental studies, with sizes typically limited to a few millimeters for well-known systems (e.g., MOF-5, HKUST-1) and up to 6–7 mm for cyclodextrin-based and Zn(3-ptz)2 systems; Marangoni-effect-assisted growth has yielded centimeter-long thin needles but not bulk crystals. The host-guest chemistry of MOFs allows in-situ or post-synthetic encapsulation, with charged MOFs (cationic or anionic) counterbalanced by oppositely charged guests. Anion-pillared MOFs, assembled using anionic pillars between metal nodes and organic linkers, provide a precedent for constructing ionic frameworks. Among Zn–terephthalate MOFs (e.g., MOF-5, MOF-2, and related pillar-layer systems), the present framework is related in employing terephthalate layers with pillar units but is distinguished by anionic acetate pillars and cationic Zn(DMSO)2+ chains occupying alternating channels, achieving charge compensation and open porosity. These references frame the novelty of using host-guest electrostatics to drive scalable, single-crystal homoepitaxy.

Synthesis and first crystal growth: Zinc acetate dihydrate (2.14 g, 9.75 mmol) was dissolved in 6 mL DMSO; terephthalic acid (TPA; 0.54 g, 3.25 mmol) was dissolved in 6 mL DMSO. The TPA solution was added to the zinc acetate solution (ZnOAc:TPA molar ratio 3:1), stirred for 1 min, and 2 mL of the mixture was transferred to a 20 mL glass vial (27 mm diameter). The vial was held at 40 °C. DMSO was selected due to higher TPA solubility (~20 wt%) compared to DMF (~6.7 wt%). After ~13 days, transparent square-cuboid crystals up to ~3.7 mm length formed.

Homoepitaxial growth protocol: A crystal from the first growth served as a seed in a secondary precursor solution (20 mL vial, 27 mm diameter). To suppress nucleation, the Zn:TPA molar ratio was adjusted to 4:1–5:1. The solution was replaced every 2–4 days with a freshly prepared one; upon each exchange the crystal was washed in DMSO. If residual microcrystals adhered to surfaces, the crystal was dipped in 0.6 M ZnAc in DMSO to etch surfaces, rinsed in DMSO, and, for centimeter-long crystals where microcrystals persisted, surfaces were mechanically scraped (e.g., nail file) and then washed. This stepwise process was repeated over months to extend crystal dimensions while maintaining single-crystal morphology.

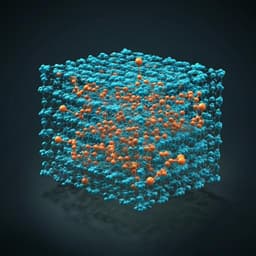

Structural characterization (SXRD): Single-crystal X-ray diffraction (SXRD) determined an orthorhombic structure (space group Pbca) with lattice parameters a = 21.8209(18) Å, b = 21.8491(11) Å, c = 35.597(3) Å, and α = β = γ = 90°. The unit cell comprises 16 cuboidal subunits. The framework consists of 2D Zn–terephthalate square lattices pillared by acetate anions via diatomic Zn nodes, forming 1D channels along b. SXRD indicates every second channel is filled with a chain of cationic Zn(DMSO)2+ complexes; alternating channels remain open.

Computational methods (DFT and electrostatics): Density functional theory calculations were performed with ORCA 5.0.4 using the B3LYP functional and 6-31G basis set. Geometry optimizations were carried out for a Zn(DMSO)6 model encapsulated within a single cuboidal framework subcell (framework atoms frozen). Electrostatic potential maps were computed and visualized (Avogadro 1.2.0) to analyze host-guest charge distribution. Optimized orientations of Zn–S bonds in adjacent subcells align with SXRD-derived orientations. Calculations show pairing of each Zn(DMSO)2+ with two acetate anions oriented to face the cation along the chain, yielding alternating acetate orientations along c and unfilled neighboring channels along b.

Imaging and monitoring growth: Sequential optical photographs documented growth in the initial solution (days 6, 8, 10, 13) and through multiple secondary growth steps (0, 4, 7, 11, 13 days), showing elongated growth along the top and bottom facets corresponding to a-b plane terminations, consistent with growth along c via alternating deposition of Zn–terephthalate layers, acetate pillars, and Zn(DMSO)2+ chains.

- A charge-transfer MOF was synthesized from zinc acetate and terephthalic acid in DMSO, forming large, transparent square-cuboid crystals without modulators.

- SXRD resolved an orthorhombic Pbca structure (a = 21.8209(18) Å, b = 21.8491(11) Å, c = 35.597(3) Å; α = β = γ = 90°) comprising 2D Zn–terephthalate square lattices pillared by acetate anions via diatomic Zn nodes, creating 1D channels along b.

- Every second 1D channel hosts a chain of cationic Zn(DMSO)2+ complexes, while alternating channels remain open, achieving charge neutrality of the anionic framework and maintaining porosity.

- DFT optimization and electrostatic potential mapping corroborate host-guest ionic pairing: each Zn(DMSO)2+ is electrostatically paired with two acetate monoanions facing the cation, with acetate orientations alternating along c, and methyl groups protruding into adjacent unfilled channels.

- Initial growth yielded crystals up to ~3.7 mm length in 13 days at 40 °C in DMSO with ZnOAc:TPA = 3:1.

- Stepwise homoepitaxial growth in secondary solutions (Zn:TPA = 4:1–5:1; periodic solution exchange and washing/etching) produced bulk crystals reaching ~19.8 × 4.2 × 4.2 mm after ~5 months, with continued extension at both ends; overall lengths up to ~2 cm were achieved.

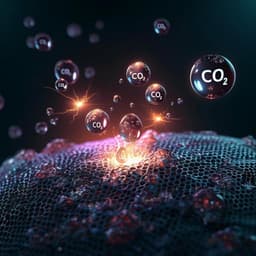

- Growth proceeds by alternating deposition of Zn–terephthalate layers, acetate pillars, and Zn(DMSO)2+ chains along c, favored by host-guest electrostatic attraction, enabling scalable single-crystal epitaxy with no apparent size limit under sustained supply.

- Practical observations include faster extension along opposite end facets (a-b plane), surface aging and reduced transparency in older middle sections, and occasional microcrystal nucleation requiring etching or mechanical removal to maintain epitaxial growth surfaces.

The work demonstrates that host-guest electrostatic attraction between an anionic, acetate-pillared Zn–terephthalate framework and cationic Zn(DMSO)2+ chains can drive continuous, single-crystal homoepitaxy. By alternating deposition of oppositely charged framework components and guest chains, the system mimics ionic crystal growth, sustaining structural coherence and enabling centimeter-scale bulk crystals. The architecture’s charge balance (two monoanionic acetate pillars per dicationic filler) inherently preserves open porosity in alternating channels, reconciling large-crystal growth with accessible voids. Compared with prior approaches that achieved millimeter-scale crystals or needle-like centimeter crystals, this method yields macroscopic, bulk single crystals with scalable dimensions. The findings suggest a generalizable strategy: selecting ionic building units and complementary charged guest species, particularly in solvents like DMSO that support high linker solubility, can enable reproducible homoepitaxy and potentially heteroepitaxy across related MOF families.

The study establishes homoepitaxy of an anionic (Zn2(BDC)2OAc)2 framework filled with 1D arrays of Zn(DMSO)2+ cations, achieving bulk single crystals extending to ~2 cm through stepwise growth over months. The host-guest charge-transfer interaction underpins continuous, shape-preserving epitaxy with no evident size limit, while retaining open porosity in alternating channels. The approach suggests broad applicability: numerous combinations of metal acetates and linear dicarboxylic acids in DMSO may enable homoepitaxy across a family of charge-transfer MOFs and heteroepitaxy between them. Future work could explore patterned heteroepitaxy with varied linkers and metal nodes, optimize growth kinetics and surface conditioning to minimize microcrystal nucleation, and further resolve guest disorder within channels.

- Structural resolution: SXRD could not fully determine the detailed molecular structure and orientations of the channel-confined Zn(DMSO) species due to disorder; assignments are supported by DFT but remain partially inferred.

- Surface quality control: During prolonged growth, microcrystals tend to nucleate on sidewalls, especially in the middle (older) sections, necessitating chemical etching and even mechanical scraping to restore epitaxial surfaces.

- Aging effects: The central, older portions of long crystals show reduced transparency indicative of aging, which may affect optical quality or defect densities.

- Process practicality: The stepwise protocol requires frequent solution exchanges, careful Zn:TPA ratio control (4:1–5:1) to suppress secondary nucleation, and extended timescales (months), which may limit throughput.

- Generality: While the authors hypothesize broad applicability to other metal acetate–dicarboxylate systems in DMSO, experimental validation across diverse chemistries and mixed-metal/linker systems remains to be demonstrated.

Related Publications

Explore these studies to deepen your understanding of the subject.