Engineering and Technology

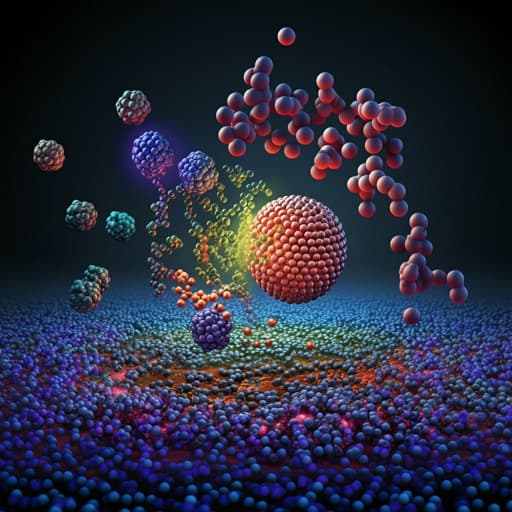

Highly Selective and Active PdCu Alloy Electrocatalyst for CO2 Reduction to CO

K. Bao, Y. Zhou, et al.

Explore the cutting-edge research by K Bao, Y Zhou, J Wu, Z Li, X Yan, H Huang, Y Liu, and Z Kang on the electrocatalytic reduction of CO2 to CO using PdCu alloys. Discover how the PdCu-2 alloy achieves an impressive Faradaic efficiency of 85% for CO, thanks to a unique synergistic effect between palladium and copper, while ensuring excellent stability and optimized performance.

~3 min • Beginner • English

Introduction

The study addresses the urgent need to convert and utilize CO2 due to environmental issues arising from excessive fossil fuel use, such as global warming and ocean acidification. Electrocatalytic CO2 reduction (CO2RR) is highlighted as a green and efficient approach compared to thermal catalysis, offering mild conditions and high conversion efficiency. However, CO2RR faces challenges including high overpotentials, low activity/selectivity of catalysts, and competition from the hydrogen evolution reaction (HER) due to similar reduction potentials, which diminishes Faradaic efficiency (FE) and product selectivity. Although noble metals like Au, Ag, and Pd show good selectivity, their high cost limits industrial scalability. The work focuses on designing low-cost, efficient PdCu bimetallic alloy catalysts to enhance CO2-to-CO conversion by tuning composition, morphology, and electronic structure to improve activity, selectivity, and suppress HER.

Literature Review

Methodology

Synthesis of PdCu alloy: Super-branched PdCu alloys were synthesized via a one-pot solvothermal method. For PdCu−2: 0.5 mmol K2PdCl4 and 1 mmol Cu(OAc)2·H2O were dissolved in a mixture of 12 mL 1-methylimidazole and 50 mL ethylene glycol, sonicated 15 min, then transferred to a 100 mL Teflon-lined autoclave and heated at 160 °C for 6 h. The product was collected by centrifugation, washed with water and ethanol (3×), and dried at 60 °C under vacuum for 12 h. Composition variants: PdCu−1 and PdCu−3 were prepared by varying precursor amounts (4 mmol and 0.25 mmol K2PdCl4, respectively). Pure Pd and pure Cu were synthesized using the same protocol but omitting the other metal precursor.

Electrode preparation: 5 mg catalyst dispersed in 1 mL 0.5 wt% Nafion aqueous solution, ultrasonicated 5 min to form ink. For carbon paper (1 × 1.5 cm), 400 µL ink was drop-cast on both sides and dried at 60 °C. For glassy carbon electrodes (GCE, 3 mm diameter), 6 µL dispersion was drop-cast and dried at room temperature.

Electrochemical measurements: LSV performed from 0 to −1.8 V vs SCE in N2- and CO2-saturated 0.5 M KHCO3 using GCE as working electrode, SCE reference, and Pt counter; potentials converted to RHE by E(RHE)=E(SCE)+0.241+0.059×pH. CO2RR tests used a two-chamber H-cell separated by Nafion 212, each chamber with 35 mL CO2-saturated 0.5 M KHCO3 and 30 mL CO2 headspace. Prior to chronoamperometry, 50 CV cycles between 0 and −1.8 V vs SCE were applied to activate the catalyst. Gas products (CO, CH4, C2H4, C2H6) were analyzed by Pana A60 GC; H2 by East-West Analysis GC. Liquid products were analyzed by 1H NMR (Bruker AVANCE III 400) with 500 µL electrolyte, 100 µL D2O, and 0.05 µL DMSO as internal standard. Faradaic efficiency FE = (z n F)/Q × 100%, where z is electron number, F = 96485 C mol−1, n product moles, and Q total charge.

Characterization: ICP-OES for composition; SEM, TEM, HRTEM, and EDS mapping for morphology and distribution; XRD for phase (JCPDS references Pd 05-0681, Cu 01-1241, PdCu 48-1551); XPS for surface chemical states (Pd 3d, Cu 2p). Electrochemical active surface area estimated via double-layer capacitance (Cdl) from CV at various scan rates; BET specific surface area measured. Electrochemical impedance spectroscopy (EIS) at open circuit with R(C(RW)) equivalent circuit for charge-transfer resistance (Rct); transient photovoltage (TPV) for charge retention and transfer, extracting decay time constant τ. Stability tested at −0.9 V vs RHE for >17 h, with post-reaction SEM and XRD.

Key Findings

- Composition and morphology: ICP-OES mass ratios Pd:Cu for PdCu−1, PdCu−2, and PdCu−3 were 83:17, 60:40, and 49:51, respectively. PdCu−2 forms 3D multi-branched “sea-cucumber-like” particles (~500 nm overall; branch length 50–100 nm, width 20–50 nm). EDS shows uniform Pd and Cu distribution.

- Structure and electronic state: XRD shows single-phase PdCu alloy with peaks at 2θ ≈ 41.42°, 48.21°, 70.54°, 85.29° corresponding to (111), (200), (220), (311) planes (JCPDS 48-1551). With increasing Cu, PdCu peaks shift to higher angles indicating lattice contraction. XPS: For PdCu alloys, Pd 3d binding energies shift negatively (~−0.1 eV) relative to pure Pd; in PdCu−2, Pd0 3d5/2 at 335.3 eV and 3d3/2 at 340.6 eV; Pd2+ at 336.2 eV and 341.5 eV. Cu 2p in PdCu−2 shows positive shifts vs pure Cu: Cu0 2p1/2 at 932.0 eV (+0.4 eV), Cu2+ 2p1/2 at 934.2 eV (+0.7 eV). Increased oxidized Pd and Cu fractions (~1:2 oxidized:zero-valent) with higher Cu content. The electronic interaction indicates electron transfer from Cu to Pd, modifying the d-band and adsorption energies.

- LSV and onset: PdCu−2 exhibits a more positive onset in CO2-saturated electrolyte (−0.56 V vs RHE) compared to N2-saturated (−0.75 V). At −0.9 V vs RHE, current density increases from −2.55 to −7.76 mA cm−2 in CO2 vs N2 electrolyte. Among PdCu−1/−2/−3, PdCu−2 shows the highest current density and smallest onset potential in CO2.

- Product selectivity and activity: Only gaseous products observed for Pd and PdCu alloys (CO and H2). PdCu−2 achieves a maximum FE(CO) of 85% at −0.9 V vs RHE, with corresponding current density −7.76 mA cm−2. FE(CO) increases from 53.9% at −0.7 V to 85% at −0.9 V, then declines at more negative potentials. Pure Pd shows maximum FE(CO) 65.31% at −0.8 V. PdCu−1 shows reduced FE(CO) relative to Pd due to small Cu incorporation; PdCu−2 (balanced Pd/Cu) maximizes FE(CO); PdCu−3 (higher Cu) decreases FE(CO) due to altered *CO adsorption. Pure Cu produces multiple carbon products with poor FE/selectivity.

- Surface area and kinetics: PdCu−2 has the largest electrochemically active surface area (highest Cdl) and the largest BET surface area (13.9592 m2 g−1) among the catalysts. EIS reveals significantly lower Rct for PdCu alloys vs pure metals; PdCu−2 shows the smallest semicircle and Rct ≈ 32 Ω, indicating faster charge transfer.

- Charge dynamics (TPV): Decay time constants τ: PdCu−3 0.173 ms, Cu 0.203 ms, Pd 0.256 ms, PdCu−1 0.286 ms, PdCu−2 0.313 ms. The longest τ for PdCu−2 indicates longer charge retention and higher electron concentration at the surface, favoring CO2 activation and CO formation.

- CO2 adsorption: CO2 adsorption capacity decreases with decreasing Pd content: PdCu−1 > PdCu−2 > PdCu−3.

- Stability: PdCu−2 maintains ~−5 mA cm−2 for over 17 h at −0.9 V vs RHE with minimal morphological change (slightly rougher surface) and slightly weaker XRD peak intensities post-reaction.

- Mechanistic proposal: CO2 preferentially adsorbs on Pd sites; electrons accumulate on Cu-rich regions facilitating activation to *CO2 and reduction through *COOH to *CO; appropriate Pd oxidation state ratio and alloying-induced electronic/strain effects enhance *COOH adsorption and *CO desorption; increased energy barrier for *CO protonation from Cu incorporation promotes CO selectivity.

Discussion

The work demonstrates that tailoring Pd–Cu alloy composition and morphology yields a catalyst (PdCu−2) that significantly improves CO2-to-CO electroreduction performance versus pure Pd or Cu. Alloying introduces synergistic electronic and geometric effects: (1) electronic interaction (electron transfer from Cu to Pd) shifts Pd and Cu binding energies, tunes the d-band, and optimizes adsorption energies for key intermediates (*CO2, *COOH, *CO), enhancing CO formation and facilitating CO desorption; (2) tensile strain from alloying contracts the lattice, further modifying the electronic structure; (3) morphology (3D branched nanostructures) increases active surface area (higher Cdl and BET) and provides abundant active sites; (4) improved charge transfer (lower Rct) and longer charge retention (largest TPV τ) increase local electron availability, accelerating CO2 activation and reduction steps while suppressing further protonation of *CO, which favors CO over deeper reductions and HER. Collectively, these factors deliver higher FE(CO) (up to 85% at −0.9 V vs RHE), higher current densities, and stable operation for >17 h. The mechanistic scheme aligns with observed selectivity trends: balanced Pd/Cu composition maximizes CO selectivity, while excessive Cu weakens *CO adsorption/desorption balance and reduces CO FE; pure Cu promotes multi-carbon formation with lower selectivity. Thus, composition-controlled PdCu alloys address the core challenges of CO2RR by lowering overpotential, enhancing activity/selectivity, and mitigating HER competition.

Conclusion

By optimizing the Pd:Cu ratio via a solvothermal synthesis, a super-branched PdCu alloy (PdCu−2, feed molar ratio 1:2) was identified as an efficient CO2-to-CO electrocatalyst, achieving FE(CO) of 85% at −0.9 V vs RHE and current density of −7.76 mA cm−2, with stable performance for over 17 h. Structural and spectroscopic analyses confirmed single-phase alloying and electronic modulation (XPS shifts, increased oxidized Pd fraction), which together with high surface area, low charge-transfer resistance, and prolonged surface charge retention account for the superior CO2RR activity and selectivity. The strategy demonstrates that PdCu alloying can reduce noble metal usage and cost while enhancing performance, and provides insights into charge-transfer behavior and intermediate adsorption tuning. Future work could extend to precise surface/oxidation-state engineering, operando spectroscopy to validate intermediate binding energetics, and scale-up in gas-diffusion electrodes for higher-rate CO production.

Limitations

Related Publications

Explore these studies to deepen your understanding of the subject.