Engineering and Technology

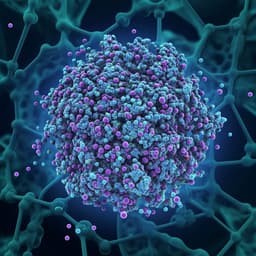

Highly durable and sustainable heterogeneous fabric using in-and-out fluorinated urethane coating for elimination of bacteria and oil-water separation

M. Choi, S. Park, et al.

This innovative research explores a novel coating material for enhancing the oil-water separation capabilities of porous activated carbon fabric (ACF). The team achieved remarkable hydrophobic properties, exceptional bacterial blocking efficiency, and durability through the use of fluorinated polyurethane coatings. Conducted by a dedicated group of researchers from Yonsei University and the Agency for Defense Development, this study paves the way for advanced filtration technologies.

Related Publications

Explore these studies to deepen your understanding of the subject.