Engineering and Technology

High-resolution flexible iontronic skins for both negative and positive pressure measurement in room temperature wind tunnel applications

J. Wang, X. Wei, et al.

Wind tunnel measurements of surface pressure on aircraft models require conformal, high-resolution, wide-range sensors capable of detecting both negative and positive pressures because pressure on an airfoil varies with local velocity (Bernoulli principle). Traditional methods—pressure taps (invasive, require tubing, difficult near trailing edges) and pressure-sensitive paints (non-invasive but limited resolution, weather sensitivity, and occlusion)—have limitations for real-time, distributed measurements on complex, curved surfaces. Flexible pressure-sensor skins have emerged but typically offer limited sensitivity and narrow ranges of only a few kilopascals, suiting only low-speed applications. Iontronic capacitive sensors, which leverage electric double layers (EDLs) at electrode–ionic conductor interfaces, can achieve ultrahigh sensitivity and wide ranges by engineering interfacial microstructures; however, existing iontronic sensors have not addressed negative pressure sensing common in aerospace. This work presents a flexible iontronic skin integrating two sensors tailored for negative (S_n) and positive (S_p) pressure ranges, targeting room-temperature wind tunnel applications, with high pressure resolution across −100 to 600 kPa and compatibility with curved aircraft surfaces.

- Pressure taps and pressure-sensitive paints are standard in wind tunnel testing but face invasiveness, tubing constraints, poor resolution, environmental instability, and line-of-sight limitations for cameras.

- Flexible pressure-sensor skins have been investigated for aerodynamic applications but typically suffer from low sensitivity and narrow operating ranges (few kPa), limiting them to low-speed scenarios.

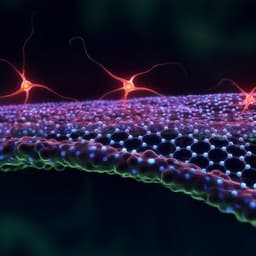

- Iontronic pressure sensors replace the traditional dielectric with an ionic soft material to form EDLs, enabling capacitance dominated by interfacial contact area rather than electrode separation. Prior designs use microstructured interfaces to achieve high compressibility and sensitivity over broad ranges. Despite progress, prior iontronic sensors have not been engineered to detect external negative pressure relevant to aerospace conditions.

- Recent studies have demonstrated strategies for high sensitivity, linearity, and wide range using intrafillable microstructures and tailored network topologies, informing the present bi-intrafillable microstructure approach for enhanced performance and bandwidth.

Sensor concept and structure:

- Two iontronic capacitive sensors were developed for negative (S_n) and positive (S_p) pressure. Both are sealed devices comprising: microstructured top electrode (Au-coated polyimide, PI-Au), flat PI-Au bottom electrode, a microstructured ionic gel film between electrodes, and a PDMS spacer to fix the interlayer distance and form a sealed chamber equilibrated to ambient pressure.

- Interfacial microstructures: a bi-intrafillable configuration combining microstructures on both the electrode (~15 µm features) and ionic gel (~2.2 µm features) was selected via finite element analysis (FEA) to maximize contact-area modulation at high pressures and reduce interlocking for fast dynamics. Feature size mismatch mitigates mechanical interlocking, improving response-relaxation times.

Negative-pressure sensor (S_n):

- Uses a thicker ionic gel such that, at rest, the gel fully contacts the top electrode, introducing a pre-contact interfacial pressure (P_i). External negative pressure reduces interfacial contact pressure, decreasing contact area and capacitance.

- Assembly includes application of a 100 kPa pre-pressure to establish full contact, followed by sealing under −40 kPa to bond the top layer and spacer before releasing the pre-pressure.

Positive-pressure sensor (S_p):

- Uses a thinner ionic gel so that the top electrode is initially separated by an air gap (≈10 pF baseline). Positive pressure initiates contact, transitioning from small air-gap capacitance to high EDL super-capacitance, enabling high sensitivity over a wide range up to 600 kPa.

Ionic gel preparation and properties:

- Double-network ionic gel composed of P(VDF-HFP), polyurethane (PUA), and ionic liquid [EMIM][TFSI], fabricated by solution casting onto a sandpaper template and UV curing, then peeling. The double network enhances crosslinking to prevent IL leakage under 1 MPa load and provides fatigue resistance under compression.

- Mechanical and environmental characterization: maximum fracture energy ≈427.1 J·m⁻²; tunable Young’s modulus via PUA content (selected 10 wt% PUA for balance of properties); negligible drift over 5000 compression cycles at 1 MPa; stable cyclic compression across relative humidity 12–98%; thermal stability up to 180 °C.

- Electrical characterization via AC impedance: equivalent circuit fitting yielded EDL capacitance per unit area and conductivity (σ ≈ 8.07 × 10⁻2 S·m⁻1). Conductivity was insensitive to PUA content.

Electrode microstructure fabrication:

- Microstructured PDMS molds replicated from commercial sandpaper; PI precursor cast and cured on PDMS mold to yield microstructured PI films (~40 µm). PI surfaces were plasma treated and NaOH-treated; 300 nm Au deposited by sputtering to form electrodes.

Sensor assembly details:

- Four-layer stack: bottom electrode, PDMS spacer (35 µm; ring inner side 3 mm, outer 5 mm), ionic gel layer, and microstructured top electrode/encapsulation. Plasma treatment used to activate bonding surfaces. S_n assembled with pre-pressure and negative-pressure sealing steps; S_p assembled without pre-contact.

Characterization setups:

- S_n measured in a custom chamber with pressure gauge, controlled inlet/outlet valves; LCR meter captured capacitance vs. controlled negative pressure.

- S_p characterized across 0–600 kPa positive pressure; dynamic response assessed for step loads (e.g., 100 kPa) and vibration frequencies up to 400 Hz.

- Mechanical durability tested under up to 10,000 compression cycles (peak 420 kPa) and 5000 bending cycles (radii ~4.2–4.4 mm). Environmental tests: humidity and temperature effects documented; temperature drift noted with potential calibration.

Wind tunnel experiments:

- Room-temperature wind tunnel with 245 mm test section providing stable flow. A NACA-0012 airfoil (chord 150 mm) mounted with laminated S_n and S_p arrays along the chord (sensing units N1–N4) on curved surfaces.

- Free-stream velocity (U∞) measured by commercial anemobarometer; angles of attack (AOA) varied 0–35°.

- Multi-channel synchronous acquisition circuit: capacitance-to-digital converter (CDC), FPGA controller, wireless module; data processed on PC to map capacitance to pressure and generate spatial pressure distributions along normalized chord x/c.

- Validation: sensor readings compared with a commercial pressure gauge at the leading edge under varying U∞ and AOA.

- Overall performance:

- Integrated flexible skin incorporating S_n (negative) and S_p (positive) sensors measures pressures from −100 kPa to +600 kPa with high resolution and conforms to curved wing surfaces.

Negative-pressure sensor (S_n):

- Pressure resolution: −20 Pa (0.025%) across the negative-pressure regime (−100 kPa to −10 Pa).

- Sensitivities: ~1.60 × 10⁻3 pF·kPa⁻1 (0 to −10 kPa), ~1.69 × 10⁻3 pF·kPa⁻1 (−20 to −10 kPa), ~1.58 × 10⁻3 pF·kPa⁻1 (−20 to −100 kPa).

- Dynamic response: relaxation time 38.7 ms at −80 kPa (includes valve and gas transit; intrinsic sensor likely faster).

- Stability: highly repeatable C–P curves across devices; negligible drift over 5000 bends (radius 4.2 mm) and under repeated cycles up to −80 kPa; stable across humidity; temperature increases signal via ion mobility but can be calibrated.

Positive-pressure sensor (S_p):

- Working range: 0–600 kPa covering commercial aircraft pressure regimes.

- Sensitivities: average ~2.52 × 10⁻2 pF·kPa⁻1 (<50 kPa), ~9.43 × 10⁻2 pF·kPa⁻1 (50–200 kPa), ~4.21 × 10⁻2 pF·kPa⁻1 (200–600 kPa).

- Limit of detection (unloaded): 0.05 Pa.

- Pressure resolution under load: resolves 100 Pa (0.025%) across base pressures of 20, 200, and 400 kPa; demonstrated 85 Pa increment at 400 kPa (0.02%).

- Speed: response 0.9 ms and relaxation 1.8 ms for 100 kPa steps; bandwidth supports vibration detection up to 400 Hz and superposition with static loads.

- Durability: negligible drift over 10,000 compression cycles at 420 kPa; robust after 5000 bending cycles (radius 4.4 mm).

Wind tunnel validation (NACA-0012 airfoil, room temperature):

- Sensor arrays adhered conformally along the chord (N1–N4). At AOA = 20°, as U∞ increased from 1.2 to 12.5 m·s⁻1, S_n showed monotonic negative capacitance changes consistent with commercial pressure gauge at the leading edge (N2).

- AOA detection: clear stepwise capacitance changes for AOA increments of 5° across U∞ = 3.5, 6.8, 9.6, 11.2 m·s⁻1; minimum capacitance near AOA ≈ 20°; beyond 20°, flow separation reduced negative pressure at the leading edge.

- Pressure mapping: along x/c, highest pressure near x/c ≈ 0.2 (N2). Total surface pressure increased from AOA 10° to 20°, then decreased beyond 20° due to separation. For AOA 10° and 20° across U∞ 3–11 m·s⁻1, pressures at all sensing points on the tested surface were negative, indicating lift; total pressure magnitude increased with U∞.

Comparative advantages:

- Thin, flexible, conformal skin; wide pressure range; high resolution and bandwidth; potential integration advantage over rigid MEMS sensors and non-invasive paints with lower resolution.

The study addresses the aerospace need for conformal sensors capable of resolving both negative and positive pressures with high resolution over a broad range. By engineering the iontronic interface—using a pre-loaded contact for S_n and an initially separated configuration for S_p—and optimizing bi-intrafillable microstructures with feature size mismatch, the sensors transform small pressure variations into large, fast, and stable capacitance changes. The double-network ionic gel provides mechanical robustness, environmental stability, and consistent electrical performance, enabling reliable long-term operation under high pressures, repeated bending, and dynamic conditions. Wind tunnel experiments on a NACA-0012 airfoil validate accuracy versus a commercial gauge, real-time AOA detection, and spatial pressure mapping along the chord, demonstrating relevance to aerodynamic characterization (e.g., identifying separation and lift trends). The ability of S_p to measure both static pressure and vibrations up to 400 Hz consolidates sensing modalities into a single, flexible device, offering practical benefits for aircraft testing and potential in-flight monitoring. Compared with traditional pressure taps and paints, the presented iontronic skin provides minimally invasive, high-resolution, and wide-range measurements on curved surfaces, meeting key requirements for modern aerodynamics research.

This work introduces a flexible iontronic skin integrating two complementary sensors to capture both negative (S_n) and positive (S_p) pressures with high resolution across −100 kPa to +600 kPa, fast dynamics (down to sub-millisecond), and strong durability. The skin conforms to curved airfoil surfaces and enables real-time pressure distribution mapping and AOA detection in room-temperature wind tunnels, aligning well with aircraft testing needs. The approach demonstrates an effective path to replace or augment conventional pressure taps and paints with a thin, robust, and sensitive skin. Future work may extend operation to low-temperature environments, scale sensor arrays for higher spatial resolution, and integrate on-board calibration (e.g., temperature compensation) and wireless data systems for in-situ flight testing.

- Temperature sensitivity and drift: signal magnitude increases with temperature due to ion mobility; although calibration can correct this, temperature changes can introduce drift.

- Low-temperature operation: iontronic sensors may not function normally in wind tunnels operating at low temperatures (as low as −50 °C), limiting current applicability primarily to room-temperature tests.

- Initial microstructure interlocking in S_n can slightly affect sensitivity in the very low negative-pressure range before full elastic contact is established.

Related Publications

Explore these studies to deepen your understanding of the subject.