Engineering and Technology

High frequency beam oscillation keyhole dynamics in laser melting revealed by in-situ x-ray imaging

Z. Wu, G. Tang, et al.

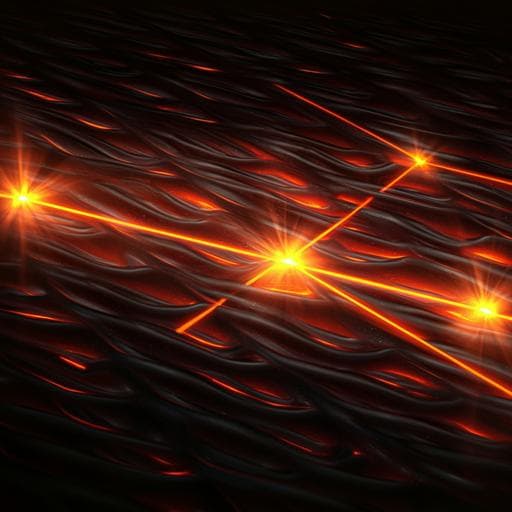

Laser powder bed fusion (L-PBF) aims to transition from rapid prototyping to high-throughput manufacturing. While standard linear scans with Gaussian beams provide a workable process window at nominal powers (<500 W) and speeds (<1500 mm s−1), they face limitations at higher productivity targets, including uncontrolled porosity and bead-up arising from high peak fluence. High-speed beam oscillation offers a means to spatially and temporally redistribute laser energy, potentially increasing productivity, improving build quality, and enabling microstructure control. Prior success of beam oscillation has been shown mainly in laser welding at up to kHz frequencies, but L-PBF’s higher scan speeds demand multi-kHz oscillation, which has been enabled by piezo-actuated mirrors. The central question addressed here is how oscillating beam strategies affect keyhole and melt pool dynamics at kHz frequencies relevant to L-PBF and how those dynamics influence defect formation and surface patterns. The purpose is to reveal spatiotemporal keyhole evolution under oscillation via in-situ synchrotron X-ray imaging and validate observations with a multiphysics model to inform process control strategies.

Previous studies on laser oscillation largely focus on welding. Early work demonstrated benefits of oscillating beams for tailored blanks and defect healing, gap bridging, and improved penetration in dissimilar joints. Across 20–1000 Hz oscillation, reports show altered melt pool shape/topology, wider heat dissipation, and reduced brittle fusion zones. Oscillation patterns (e.g., circular) can reduce thermal gradients and interrupt fluid flow, refining grains and improving ductility; similar grain refinement was observed up to ~80 Hz. However, these welding-oriented frequencies and scan conditions differ from L-PBF, which requires significantly higher oscillation frequencies due to higher linear scan speeds. The current work extends understanding to multi-kHz oscillation relevant to L-PBF, addressing a gap where prior knowledge came mainly from metallography or top-down imaging rather than operando subsurface visualization.

Experiments: Dynamic X-ray radiography (DXR) was conducted at the APS 32-ID-B beamline (Argonne National Laboratory) using high-energy synchrotron X-rays to image Ti-6Al-4V melt pool/keyhole dynamics through optically opaque samples. The setup employed a ytterbium fiber laser (IPG YLR-500-AC, 1070 nm, max 540 W) coupled to a GE fast scanning mirror (FSM) operating at 5.5 kHz upstream of a galvo scanner (IntelliSCANde 30) with a 340 mm f-theta lens. This enabled circular beam oscillation superimposed on linear scanning with a focused spot size of ~160 µm. The X-ray beam was orthogonal to the laser and imaged via a LuAG:Ce scintillator (100 µm) and a high-speed camera (Photron SA-Z) at 50 kHz. Samples were Ti-6Al-4V plates (no powder) ~50 mm long, 3 mm tall, 0.5 mm thick in 1 atm argon at room temperature. Keyhole depth was measured from the top surface to the keyhole bottom in DXR images (contrast from local density changes via Beer–Lambert). A 3×5×6 parameter matrix surveyed 3 laser powers (300, 400, 500 W), 5 circular oscillation diameters (0, 0.09, 0.12, 0.18, 0.24 mm), and 6 linear scan speeds (0.2, 0.4, 0.6, 0.8, 1.0, 1.2 m s−1), totaling 90 conditions. Simulations: A validated FaSTLAB (FAST Lattice Boltzmann) multiphysics model simulated melt pool dynamics, including ray tracing with multiple reflections, phase transitions, liquid flow, evaporation, and recoil pressure. The model omits explicit metal vapor and cover gas dynamics. Simulations used a 3200×960×1920 µm domain at 10 µm resolution with 100 ns time steps. Five representative conditions (two linear, three oscillating) were modeled for comparison with experiments. Data analysis included extraction of keyhole depth time series, Fourier analysis to identify characteristic frequencies, and laser absorption estimation from traced rays in simulations.

- Oscillating vs linear keyhole depths: At 400 W, 400 mm s−1, 0.12 mm diameter, oscillating keyholes exhibited up to ~125 µm depth variation within a single oscillation unit. The average keyhole depth with oscillation was 99 ± 39 µm vs 267 ± 28 µm without oscillation. Simulated linear depth averaged 284 ± 7 µm; simulated oscillating average was 146 ± 22 µm. - Governing factors: Keyhole depth extrema are not synchronous with transient laser speed extrema. Local pre-heat (underlying temperature) strongly influences depth, often more than instantaneous speed. Positions A–D in an oscillation cycle show distinct thermal histories and shapes; positions with remelting (C) are deepest. - Laser absorptivity dynamics: Linear scans show higher average absorption (~70%) with shorter-range fluctuations, consistent with deeper keyholes. Under oscillation, absorptivity varies over a longer range and is phase-shifted relative to transient speed by ~50 µs (~0.56π), indicating absorptivity is driven by keyhole morphology rather than speed alone. - Chevron pattern formation: Oscillation induces periodic surface swelling synchronized with keyhole movement, producing chevron units whose number matches oscillation cycles. Oscillation reduces the melt pool length-to-width ratio relative to linear scans, implying potential for melt-pool shape control and periodic solidification. - Parametric trends (90 conditions): Across 300, 400, 500 W, average keyhole depth decreases with increasing oscillation diameter and scan speed (reduced energy density). Depth reduction with speed is steep from 0.2 m s−1 then plateaus beyond ~0.6 m s−1 (transition toward conduction mode). - Stability (standard deviation of depth): Larger oscillation diameters generally reduce keyhole depth fluctuations. In some regimes, oscillation yields lower standard deviations than linear scans, suggesting reduced stochastic instability. - Frequency-domain behavior: FFT of depth profiles shows a characteristic peak at ~5.5 kHz for oscillating cases (the oscillation frequency) and a weaker harmonic near ~11 kHz when depth approaches zero within a cycle (e.g., 0.18 mm diameter). Linear scans lack such a narrow peak and show higher broadband intensity. - Porosity mitigation: DXR of solidified tracks shows linear scans (e.g., 400 W, 0.2 m s−1, D=0; energy density ~12.5 J mm−2) yield clusters of keyhole pores. Introducing oscillation eliminates pores even at smaller diameters (e.g., D=0.09 mm; ~8 J mm−2) and in cases with higher energy density than a porous linear baseline (e.g., 400 W, 0.4 m s−1, D=0 vs oscillating 400 W, 0.2 m s−1, D=0.12; 500 W, 0.2 m s−1, D=0.09). - Mechanistic insights for porosity: Oscillating keyholes are more equiaxed and reside in larger molten volumes, reducing collapse propensity and providing longer/safer escape paths. Keyhole shape (aspect ratio), depth, and melt pool length jointly influence pore formation and escape. - Model–experiment agreement: Maximum keyhole depths from simulations closely match experiments across tested conditions, indicating the model captures essential oscillating melt pool physics. Protrusions inside keyholes (pore precursors) were observed experimentally; the code can simulate such events though not observed in these runs.

The study addresses how multi-kHz beam oscillation alters keyhole dynamics in laser melting relevant to L-PBF. Oscillation introduces controlled, periodic fluctuations dominated by local thermal history (pre-heat) and modifies absorptivity with a measurable phase lag relative to beam speed, underscoring that geometry-driven absorption governs energy coupling. By spreading energy, oscillation reduces average keyhole depth and length-to-width ratio, and can lower stochastic instability compared to linear scans. The emergence of a strong, single-frequency signature in depth fluctuations suggests that oscillation can regulate and potentially stabilize keyhole dynamics, in contrast to broadband, less predictable linear behavior. Periodic surface swelling synchronized with oscillation cycles links process kinematics to solidification morphology (chevron pattern periodicity), opening pathways to tailor surface texture and possibly microstructure. Crucially, oscillation raises the threshold for keyhole porosity, suppressing pores in cases where linear scans produce defects, likely owing to more equiaxed, stable keyholes and altered melt pool volumes and escape times. Agreement between simulations and experiments validates the multiphysics model as a tool for deeper exploration and process optimization.

In-situ synchrotron X-ray imaging and validated Lattice Boltzmann simulations reveal that kHz laser beam oscillation produces continuous, periodic keyhole fluctuations controlled by local pre-heat and transient speed. Oscillation distributes energy over a wider area, reducing average keyhole depth and the melt pool length-to-width ratio. It imprints process periodicity onto the surface as chevron patterns synchronized with oscillation cycles. Importantly, oscillation can reduce keyhole instability and increase the threshold for porosity formation, suppressing pores under conditions that yield defects with linear scans. These findings indicate that beam oscillation is a promising strategy for productivity gains, defect mitigation, and melt-pool shape control in laser-based AM. Future work should elucidate the full mechanisms behind porosity reduction, quantify parameter-dependent phase shifts between absorptivity and speed, and extend studies to include additional physics (e.g., vapor/gas dynamics) and powder-bed conditions to guide practical scan strategy development.

- Experimental geometry: Tests were performed on thin Ti-6Al-4V plates without powder; edge effects in thin samples likely influenced fluid flow and thermal diffusion (noted discrepancies at certain oscillation positions). - Modeling scope: Current simulations omit explicit metal vapor and cover gas dynamics, which can be important in keyhole regimes. - Mechanistic completeness: A complete explanation for porosity reduction with oscillation is not yet determined; multiple interdependent factors (keyhole shape/aspect ratio, depth, melt pool length, fluid flow, thermal fields) require further study. - Parameter dependence: The observed phase shift (~50 µs) between transient speed and absorption depends on process parameters and material properties; additional experiments are needed for validation and generalization.

Related Publications

Explore these studies to deepen your understanding of the subject.